|

|

Post by Penguin45 on Jun 29, 2023 21:16:19 GMT

I'm a ways from actually using it at all before I even think about doing upgrades. I doubt it would be necessary for the things I'm likely to be making. Cleaning has now hit fourteen hours.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr The column, head and motor are now spotless. Scruffy and faded, but spotless. Opened up the front control box...  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Oh dear. Actually, that's not quite what I said. The on/off function is part of the potentiometer. It's failed, so the PO has added a separate on off switch and and made a complete mess of the wiring. That's just dangerous. He did actually run the machine whilst I was collecting it, so I didn't think much of it at the time. Anyway, wiring diagram tracked down and the correct potentiometer sourced. It was ten quid, so why make a mess like that? Whilst I'm waiting, I decided to use the time to strip the base sections off completely and repaint them.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr It's an interesting little project and there'll be a nice machine at the end of it. Chris. |

|

|

|

Post by Penguin45 on Jun 30, 2023 17:39:37 GMT

|

|

|

|

Post by Penguin45 on Jul 1, 2023 21:53:05 GMT

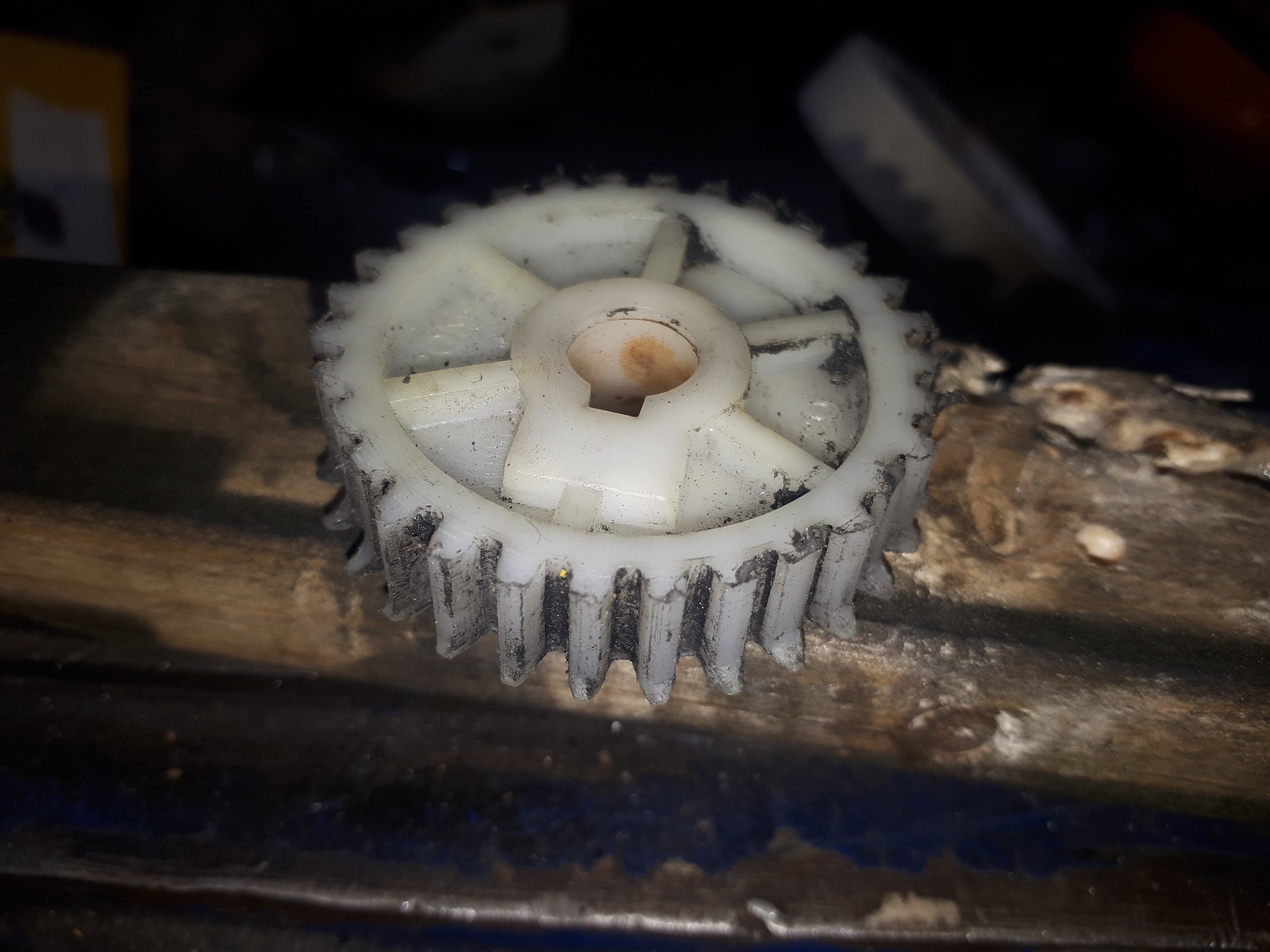

I took the head off and stripped the motor and top cover off. Cleaned out and re-greased the gear box prior to painting.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Found this. Doesn't look very healthy. I think metal replacements are available.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Head looking very yellow. I stripped out the electrics as I'm going to have to re-do a lot of them anyway, which made cleaning and painting the electrical boxes much simpler.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr And finally made a new side cover for the smaller box from an off-cut of acrylic. I should be able to start some mechanical re-assembly tomorrow when the paint has fully cured. I'm still waiting for bits and pieces which should have come on Thursday and Friday and I won't see until Monday. That's going to delay things a bit. Royal Mail really has become something of a bad joke. Chris. |

|

|

|

Post by Penguin45 on Jul 2, 2023 17:37:10 GMT

Spent a happy couple of hours putting stuff back together this afternoon.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr First on was the column. This can tilt 45° each way. Popular wisdom seems to suggest that this is not a good plan and tilting the work piece if required is far more reliable. So, spent a good while getting this plumb bob vertical, probably never to be touched again.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Head on next and various upsy downsy mechanisms refitted. New side cover for the electrical box worked out all right. All screws holes have had a tap run through to clear paint and any rogue swarf.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Other side saw the counter balance mechanism and gearbox ever re-installed. And that's as far as I can get at the moment until various new bits and pieces turn up. Pretty pleased with how it's going though. Chris. |

|

|

|

Post by Penguin45 on Jul 3, 2023 16:49:38 GMT

That should say "gearbox lever" at the end there. Anyway, still no Royal Mail, so no progress today. So, for the amusement of anyone who might be reading this, I give you my milling table perched on the table of the big Bridgeport Series I up in the engine shed at work.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr If you look closely, you can see it. C. |

|

|

|

Post by dave1800 on Jul 3, 2023 23:39:00 GMT

I have a Proxxon MF70 that would make your Clarke appear enormous. MF70David |

|

|

|

Post by Penguin45 on Jul 4, 2023 6:54:16 GMT

I had a look at one of them, but the owner said it didn't like steel much. He was mainly working with plastics and ali. He'd made some very interesting things with it though.

C.

|

|

|

|

Post by dave1800 on Jul 4, 2023 11:24:20 GMT

Yes, only really for small items and I don't use it for anything harder than alumunium. David I had a look at one of them, but the owner said it didn't like steel much. He was mainly working with plastics and ali. He'd made some very interesting things with it though. C. |

|

|

|

Post by Penguin45 on Jul 7, 2023 20:12:48 GMT

Still no post, so I can't quite finish it. Anyway, you saw the state of the wiring, so I thought I would re-do it all properly. My first action was to ring Clarke Technical and ask them to email me a copy of the wiring diagram. After a chat with a very helpful young man, he told me that they hadn't got it! I was somewhat taken aback... So, I'll have to work it out for myself then. I searched by model, by related model and finally by PCB number. This brought up results for mini lathes. I downloaded a few of them and after doing some comparisons with the wiring and switch gear in my mill, I managed to work it out. It works too, which was nice. Anyway, being a public spirited sort of chap, I drew up the resulting diagram nicely, MrsP converted it to a document and I've emailed it to the Technical Manager at Clarke. We can't have the UK Distributors not having important technical info.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Next up, I need some tee nuts. I've got one, which came with the mill (The PO had jammed it so badly he couldn't remove it), but you need a few to clamp things down properly. If only I had a mill..! Out with the angle grinder and the files.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr It's a bit crude, but it will let me clamp the vice down and make some proper ones. Eventually. Chris.

|

|

|

|

Post by Penguin45 on Jul 8, 2023 12:28:50 GMT

|

|

|

|

Post by Penguin45 on Jul 14, 2023 18:12:59 GMT

As far as repair and refurbishment work is concerned, the mill is now finished.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Labels turned up, so the front electrical box could be finished, as the fuse holder and lamp fit from the outside.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Wiring unrecognisable - neat and safe.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr New gib grub screws. Acting on advice from my mate Ady, these are stainless with a "dog" end. They will engage the gib strips more positively apparently, making them less likely to go out of adjustment. Some shoulder bolts turned up as well. Five minutes in the lathe meant that the hand wheel handles could be fitted neatly without the big ugly lock nuts. Tomorrow I will attempt to set the gibs up properly so that there is minimal play in the table, cross slide and head unit. Then try "tramming" the table to see how square and level it's finished up. Then I'll try and make something! One little side project has come to fruition.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Meet the Frankensander. Assembled from the best bits of two cr@ppy Chinese sanders and a proper motor. Barely slows down when the load is applied. Awesome. Chris. |

|

|

|

Post by dave1800 on Jul 15, 2023 14:52:02 GMT

That's looking really impressive, well done!

David

|

|

|

|

Post by Penguin45 on Jul 15, 2023 17:08:13 GMT

Cheers David. The Frankensander was put to work this morning, making corks for MrsP's various craft glassware projects.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Last two were quite tricky. Now being in the good books, I tried putting the mill to work. Bear in mind that I never, ever used one of these before and what knowledge I have is gleaned from studying the works of Blondihacks and This Old Tony on YouTube.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Chips! Yay! Facing off the ends on some 8mm aluminium. This is going to be the end panel for the table. It's a completely improvised set-up and no doubt my YouTube mentors would have conniptions. But - it works for this little piece anyway.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Being an honest sort of chap, the first one at the top is scrap. Somebody turned the Y axis handle the wrong way at a critical point. The bottom one is far from perfect, but does work.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr It fits. Nice.   Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr And after a visit to the Frankensander and a couple of licks of paint. Rather pleased with that as a first attempt. Chris. |

|

|

|

Post by Penguin45 on Jul 17, 2023 19:10:04 GMT

Levelling up the table has proved to be a bit of a headache. I'm waiting for a new dial indicator and stand (pinched in that burglary) to arrive, to try and do the job properly. I did manage to do a few tests though. Set up a length of aluminium in the vice and faced off the top surface. Results: 1st/ 29.26mm -> 29.17mm over 92.81mm. .0556° off. 2nd/ 28.44mm -> 28.27mm. .105° off. 3rd/ 27.30mm -> 27.18mm. .0741° off. The adjustment is in the pivot of the column, which I attempted between each pass. As you can see, I've made it worse!  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr You may need to blow the picture up, but you can see the taper opening as you travel up the square. I think I'll wait for the dial indicator to arrive before trying anymore adjustment and if I get nowhere, I'll have to bribe Ady to come over to the dark side for an afternoon. Chris. |

|

|

|

Post by Penguin45 on Aug 19, 2023 19:17:26 GMT

Work on the mill is continuing. I have added a tacho display, as I lack the skill to judge spindle speed with my level (complete lack!) of experience. £9.50 saw a sensor and display kit winging its way from China and a further £4.50 bought a 1 amp 12Vdc LED driver in the post.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Neatly mounted and the electrics hidden away. A complete steal for a total of £14. I've also bought a machine vice; a 4" Accu-Lock. Plenty of good reviews, despite the price point very obviously shouting "Chinese". I've taken an indicator over it and it really is very good. Unfortunately, just handling the vice saw the paint falling off! Presumably not de-greased prior to painting.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Scrubbed down with Scotchbrite, thoroughly de-greased and painted with a decent oil-based machinery paint.  Clarke CMD300 Mill Clarke CMD300 Mill by Penguin 45, on Flickr Re-assembled. I managed to keep the accuracy as well, so quite pleased. Prior to putting it back together I had to break the edges on every block ad straight edge, with the exception of the nicely chamfered jaws and their mounting blocks. At the price point I'm not going to complain. Chris. |

|