|

|

Post by Penguin45 on Oct 25, 2015 20:18:41 GMT

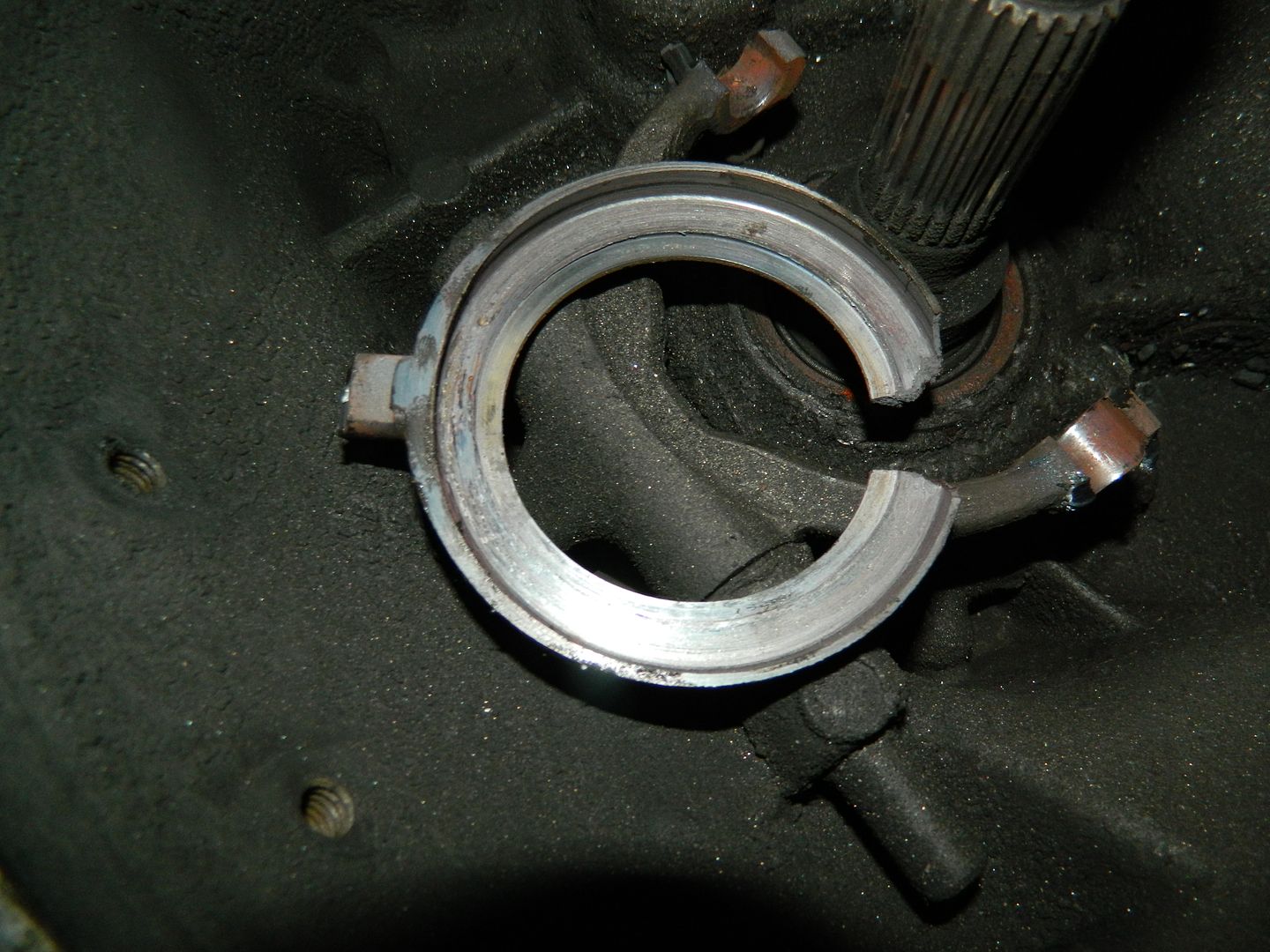

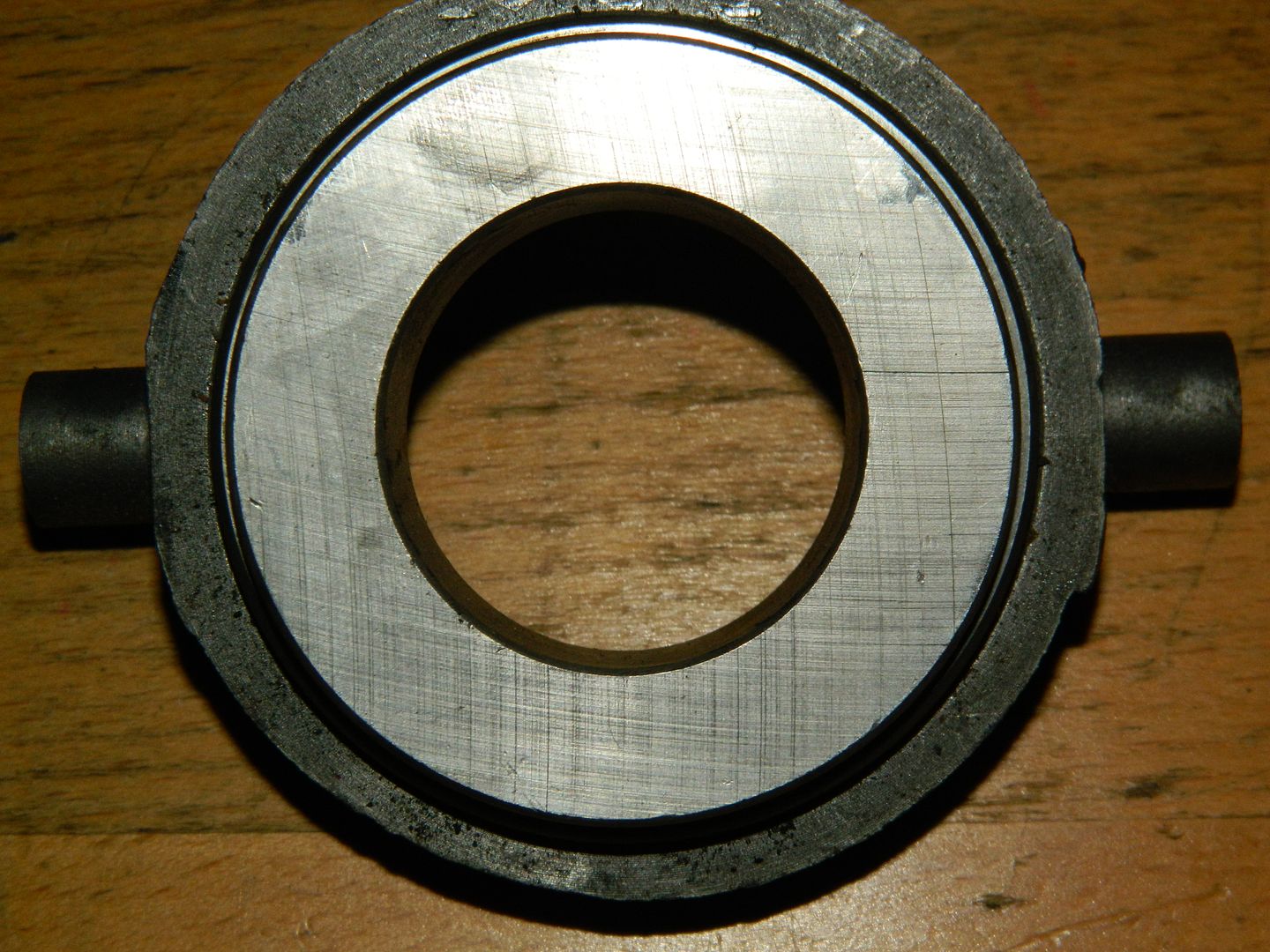

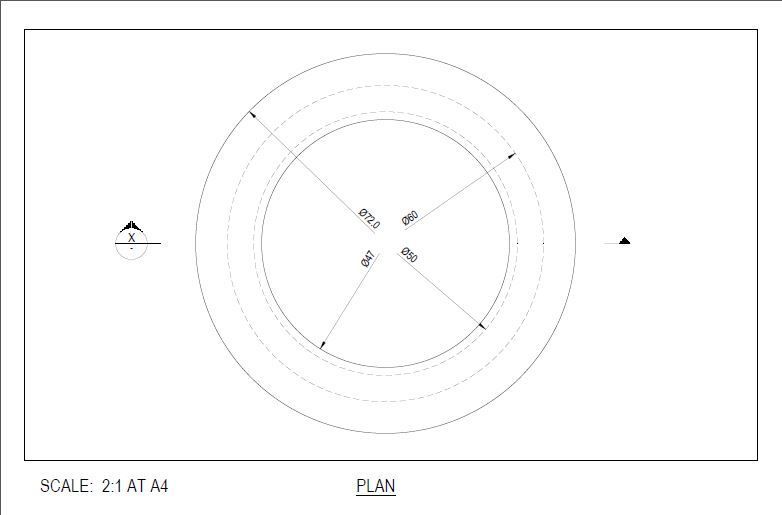

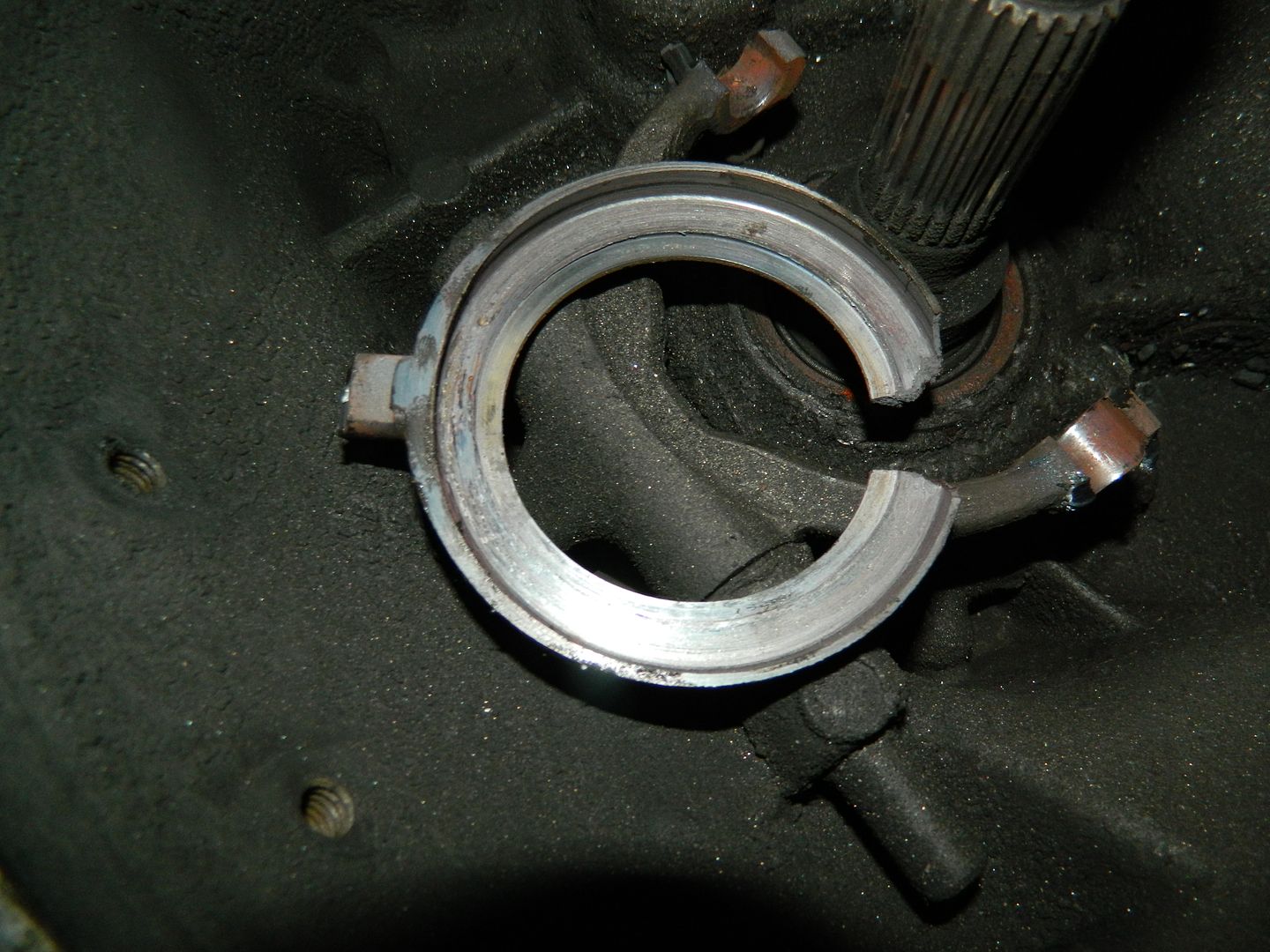

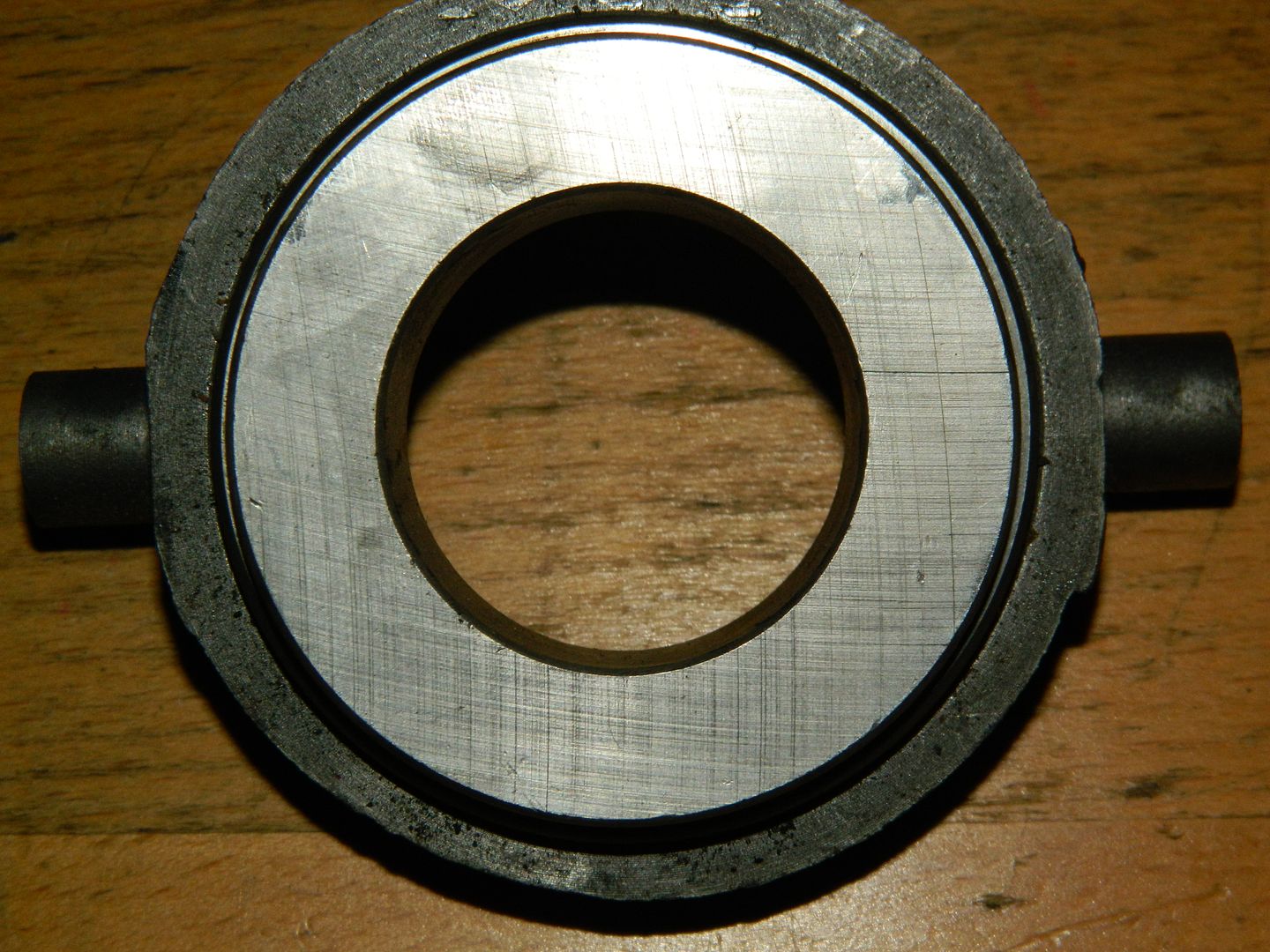

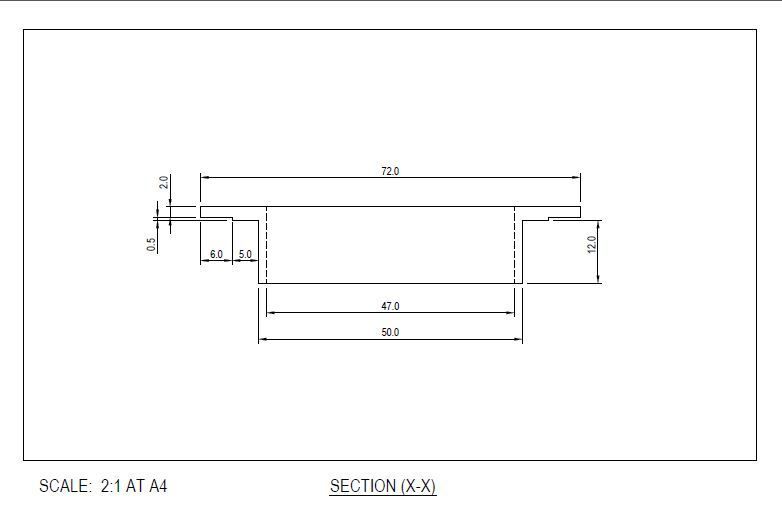

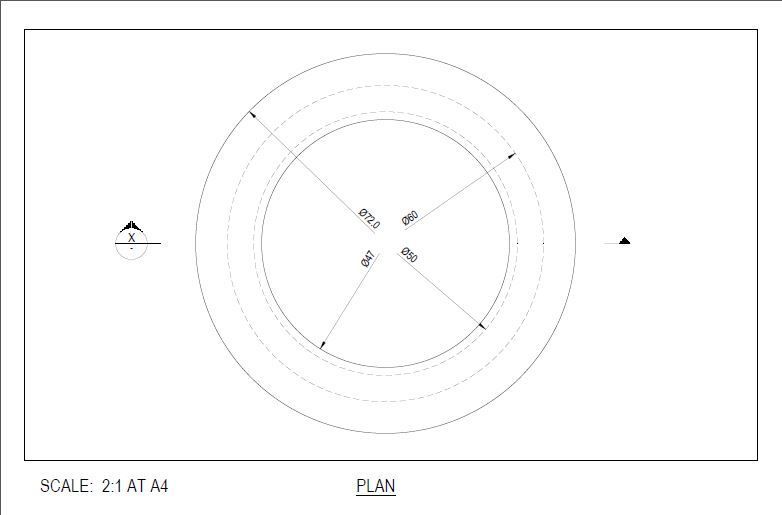

Finally made some progress with this. Having found the release bearing shattered when we pulled the engine out of Eugenie, I've been pondering alternatives due to increasing rarity and expense.   As found. Bandit1 of this parish showed me the release bearing he'd just bought for his MGB. It has a roller bearing and a face plate. I borrowed one from Chris the Painter round the corner (he has an MGB, too) and pulled it apart. It's just a standard roller bearing, with a push fit facing plate.   So, Mike Jordan came up with a worn (but intact) release bearing. Knocked the remains of the carbon out and set about some measuring. A 61910-2RS bearing is an almost exact fit in all three dimensions. It will need shimming into the housing with some .010" stock. Sketched up a facing piece, which the excellent Indiana Jones converted into a pukka engineering drawing. The rear face has a small step turned onto it to clear the rubber seal and outer edge of the bearing.  Bearing in the carrier.  Facing piece.  All pushed together.  Side view compared with new carbon release bearing. Height is spot on. Intention on fitting is to add a lightweight auxilliary return spring to the arm. Mike is suggesting that I should fabricate a depth stop mechanism as well, to restrict the overall travel of the clutch release arm. Still pondering that one. Anyway, engine will be back in the car fairly soon and we can find out how well it works. Chris. |

|

|

|

Post by Penguin45 on Jan 31, 2016 12:21:41 GMT

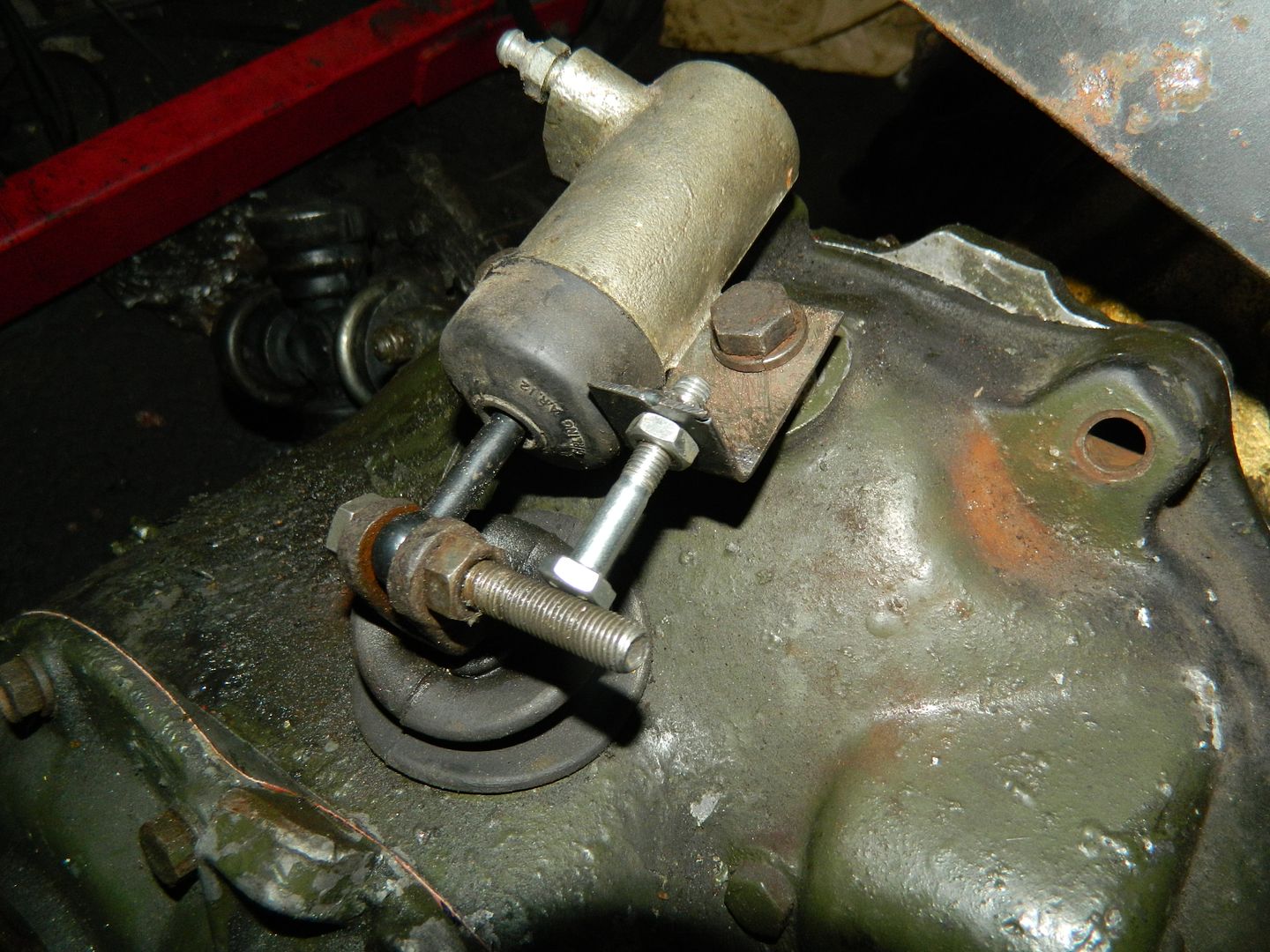

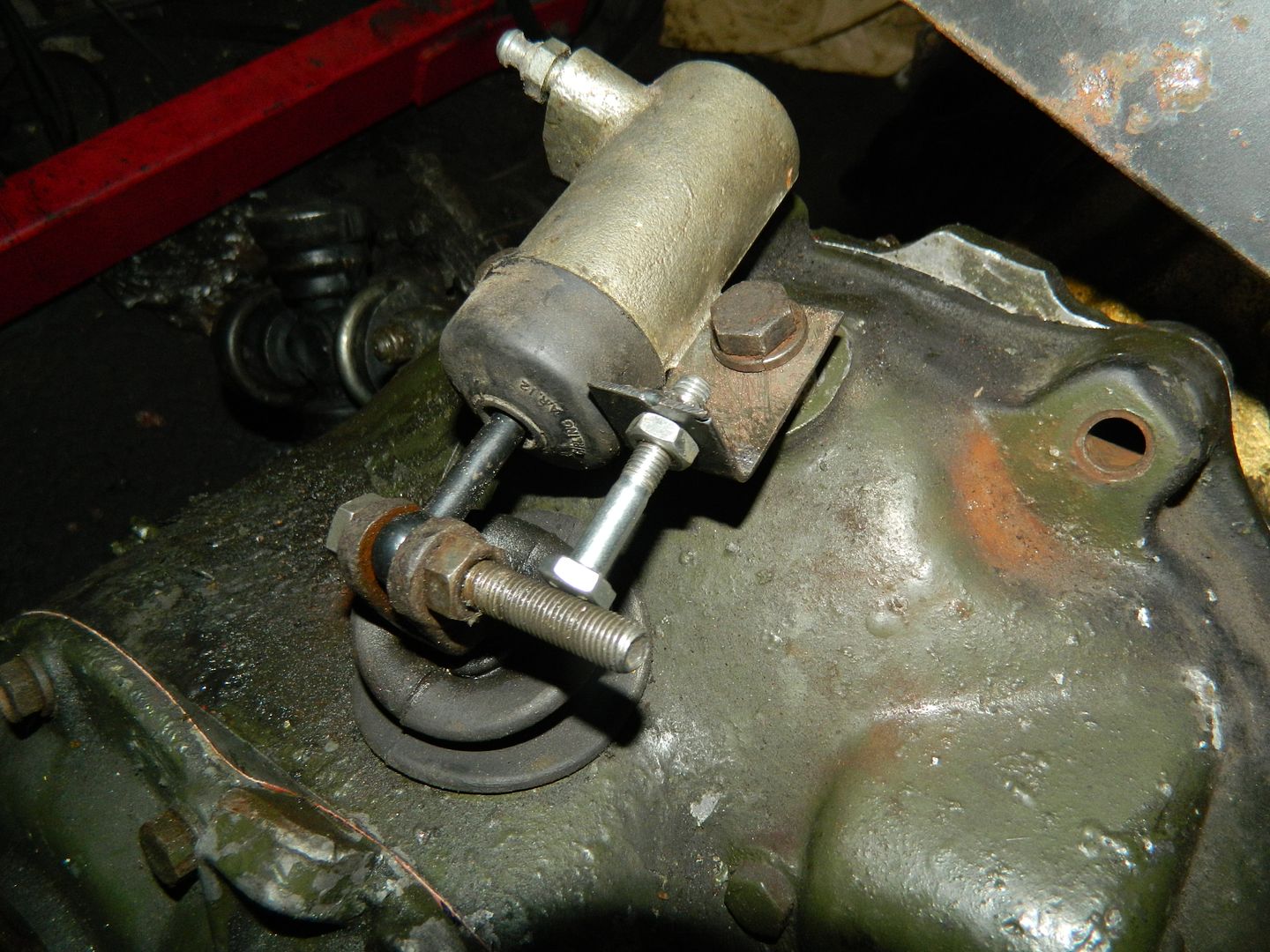

Just to tie this together a bit and help Charly see what got done:  Push rod and clevis pin as found. Both badly worn. Pushrod has been replaced.  Return stop as originally made. Clevis pin replaced with bolt. Shank threaded to allow a retaining nut to be run down to the fork on clutch arm.   Take two - bracket extended to allow a return spring to be added. It all seems to be working pretty well. Clutch action is quite light, revs don't drop with pedal depressed and there are no new or strange noises to be heard. I've done a couple of thousand miles with this now and I'm quite happy with it. Chris. |

|

|

|

Post by Penguin45 on Jan 31, 2016 12:30:22 GMT

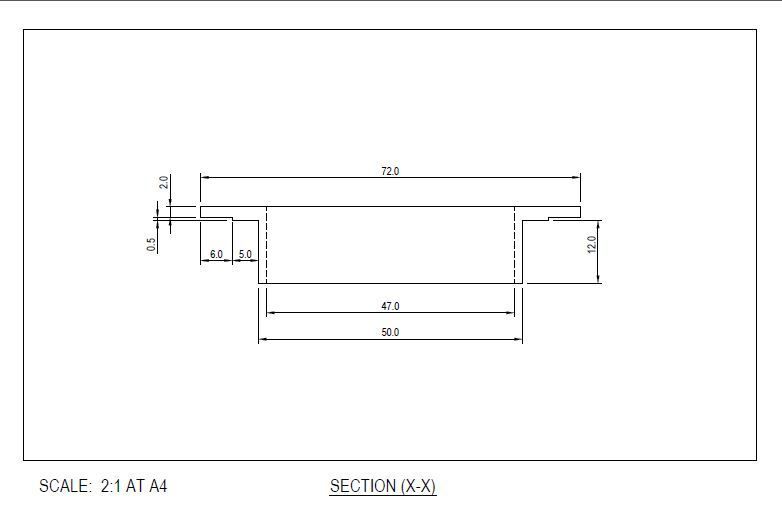

And for those far, far away contemplating doing this, here are the plans for the facing piece.   Chris. |

|

|

|

Post by indianajones on Jan 31, 2016 19:12:27 GMT

I should still have the PDFs and AutoCAD file for this lying about, shout out if you need it.

Cheers,

Andrew

|

|

|

|

Post by charlypm on Feb 2, 2016 6:18:52 GMT

I like this concept. I'm hoping my release bearing isn't too worn to use. When I pulled it apart, there was no carbon left on it. Another thought I have about it is the transmission always had trouble going into first gear, I'd have to turn off the motor some times to engage it. Would then worn bearing cause this or should I look at the synchro (baulk) rings?

|

|

|

|

Post by dave1800 on Feb 2, 2016 9:09:54 GMT

Engaging first gear cleanly can be an issue usually overcome by moving the gear stick to the second gear position and then pushing it forward. This was a trick on the non synchro first gear minis etc and I also still use it when engaging reverse on an old Toyota truck I use here sometimes. Too high an idle can make the problem worse. This stops the shaft from turning so making gear engagement easier which can be due to a number of causes including binding in the flywheel bush or the clutch plate sticking due to dried grease etc on the clutch shaft. Other causes could be a bent shaft or the synchro on first gear.

As your problem is so severe that you have to stop the engine, I would look first at whether there is any indication of the clutch sticking on the shaft as the most likely cause you can investigate now it is dimantled. It should all be dry and clean and the splines undamaged. My experience has been that synchro wear normally appears first on second gear. Another possibility is the cable adjustment but this may best be addressed when it is all back together, but worth checking now for anything obvious if you are going to dismantle the cables to stop leaks.

Regards

David

|

|

|

|

Post by charlypm on Feb 2, 2016 14:34:52 GMT

Yes, I'll check those items. Also I think I'll have my clutch disc relined, do you know the thickness?

Thanks

|

|

|

|

Post by Penguin45 on Feb 2, 2016 16:25:15 GMT

Afraid I haven't got the specs for the clutch thickness. However, GCP116 from Moss is a direct replacement and would surely be cheaper than having yours re-lined. Unless you want to uprate to kevlar linings, of course......

Chris.

|

|

|

|

Post by charlypm on Feb 3, 2016 2:30:24 GMT

No, don't need Kevlar, but lots of choices for MGB. I had no idea the clutch plate was the same. What else in the drive train is the same as other cars (Austin Healy MGB Cambridge etc.)?

|

|

|

|

Post by Penguin45 on Feb 5, 2016 18:22:38 GMT

Nothing else that I can think of, Charly. Take the clutch - you can use the friction disc, but the cover is different. Engine side you're pretty well covered by 5 bearing MGB stuff (After all, they adapted our engine to fit in their car, but most MGB owners don't know that.  . Front brakes are the M16 caliper fitted to millions of European Fords through the 60's and 70's. Rear brake cylinders are shared with the MGC, shoes with the Austin A50, A55 and A60 series cars. I think that's about it. Further to your clutch release bearing having no carbon (ie it's flush with the casting), don't think about re-using it. You'll be running metal on metal with the facing plate on the clutch cover. Chris. |

|

|

|

Post by charlypm on Feb 5, 2016 18:50:48 GMT

Nothing else that I can think of, Charly. Take the clutch - you can use the friction disc, but the cover is different. Engine side you're pretty well covered by 5 bearing MGB stuff (After all, they adapted our engine to fit in their car, but most MGB owners don't know that.  . Front brakes are the M16 caliper fitted to millions of European Fords through the 60's and 70's. Rear brake cylinders are shared with the MGC, shoes with the Austin A50, A55 and A60 series cars. I think that's about it. Further to your clutch release bearing having no carbon (ie it's flush with the casting), don't think about re-using it. You'll be running metal on metal with the facing plate on the clutch cover. Chris. |

|

|

|

Post by charlypm on Feb 5, 2016 18:51:58 GMT

Further to your clutch release bearing having no carbon (ie it's flush with the casting), don't think about re-using it. You'll be running metal on metal with the facing plate on the clutch cover.

Chris.[/quote]

No, I don't want to reuse it as is, I was thinking of using it with a bearing instead of a carbon surface.

|

|

wolseley1800

Member

Posts: 127

Attribute: The Voice of Doom!

|

Post by wolseley1800 on Mar 6, 2017 22:45:21 GMT

This is the new modified release bearing. It is a proper bearing that has been pressed into the housing. The one below has done about 7,000 miles. The bearing spins smoothly, no real marking on the face and no wear. Must mention that this is not my idea but another club member.  |

|

|

|

Post by andrewa on Mar 9, 2017 9:32:03 GMT

Sounds brilliant - as you may have picked up I'm on a noise reduction quest at the moment - does it offer and benefits in that regard?

Andrew

|

|

|

|

Post by dave1800 on Mar 9, 2017 10:11:59 GMT

I would imagine that the carbon bearing is quieter until it wears out and you have metal on metal screeching. I saw some ear plugs in the supermarket, maybe a better option than trying to quieten a Crab! I just used to love the fact that you could hear every bit of mechanical chatter so usually knew well in advance of something that was about to fail! David Sounds brilliant - as you may have picked up I'm on a noise reduction quest at the moment - does it offer and benefits in that regard? Andrew |

|

. Front brakes are the M16 caliper fitted to millions of European Fords through the 60's and 70's. Rear brake cylinders are shared with the MGC, shoes with the Austin A50, A55 and A60 series cars. I think that's about it.

. Front brakes are the M16 caliper fitted to millions of European Fords through the 60's and 70's. Rear brake cylinders are shared with the MGC, shoes with the Austin A50, A55 and A60 series cars. I think that's about it.