|

|

Post by Penguin45 on Aug 25, 2015 23:22:31 GMT

Lots of space to play in. I'm having first go..... Chris. |

|

|

|

Post by Penguin45 on Sept 9, 2015 15:14:23 GMT

And after the Matiz, indeed I have had first go.  Tie bar housing. Note serious bit of fillet welding around mounting plate. Full story HERE. Chris. |

|

|

|

Post by Penguin45 on Sept 9, 2015 19:26:11 GMT

All back together again and seems to be driving nicely.

Chris.

|

|

|

|

Post by tony on Sept 16, 2015 7:44:18 GMT

Hi, Chris

It's amazing to see your work and your garage where I cannot see a powered jacking machine. It's very hard to work with no enough room under a vehicle. Sometimes I have to do so. Good work.

Regards

Tony

|

|

|

|

Post by Penguin45 on Sept 20, 2015 17:13:21 GMT

Exhaust manifold joint re-sealed - clamp and bottom "U" clamp both worked slightly loose. Irritating weep of petrol finally nailed. Fuel line into carburettor was the culprit. Otherwise, all good.

Chris.

|

|

|

|

Post by Penguin45 on Mar 19, 2016 0:37:18 GMT

Further to a comment in Eugenie's thread a couple of month's back, the Red Dog has now been pushed into the garage for a clutch release bearing swap. Much demolition starting tomorrow then.

Chris.

|

|

|

|

Post by Penguin45 on Mar 20, 2016 23:57:33 GMT

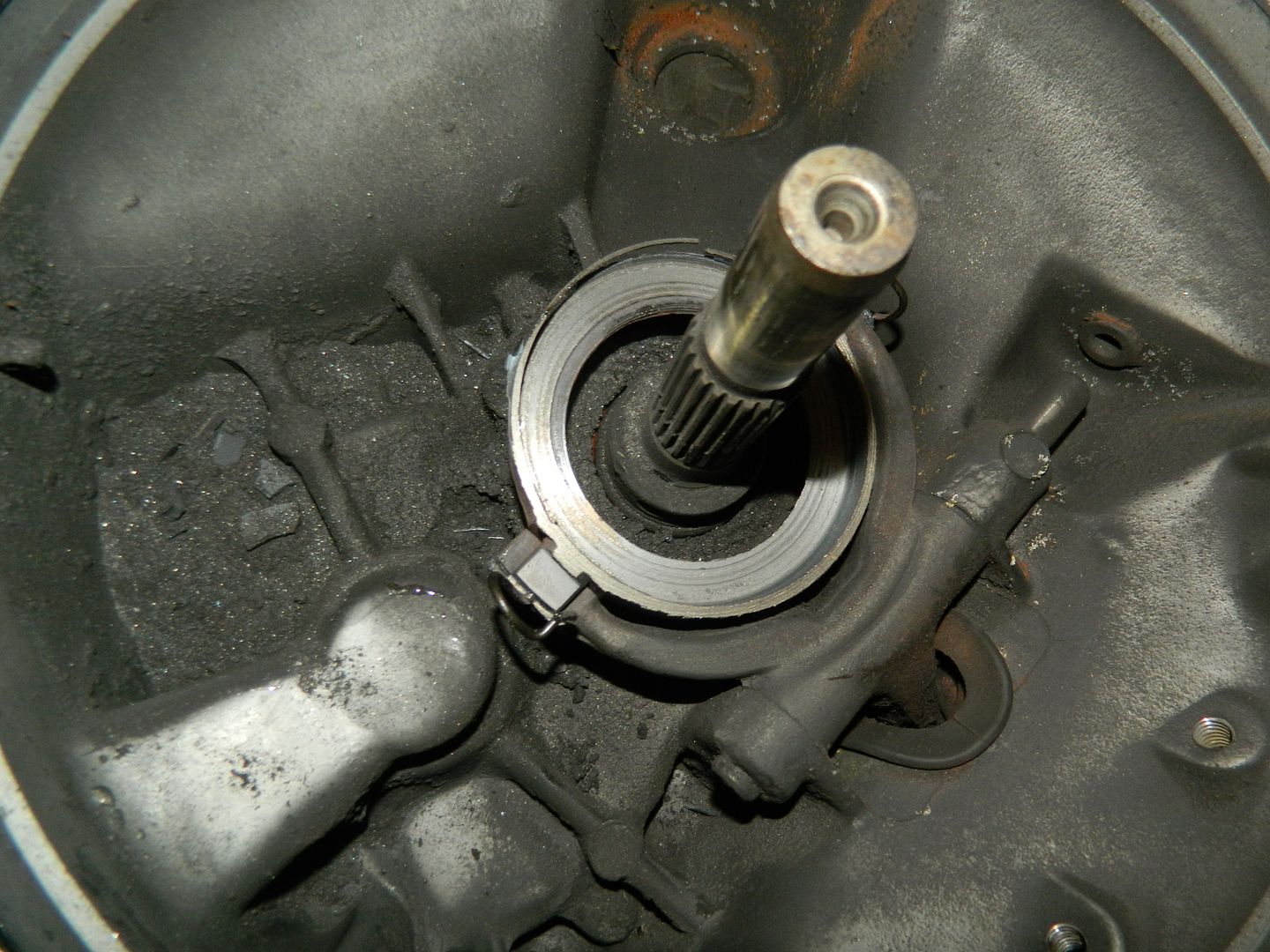

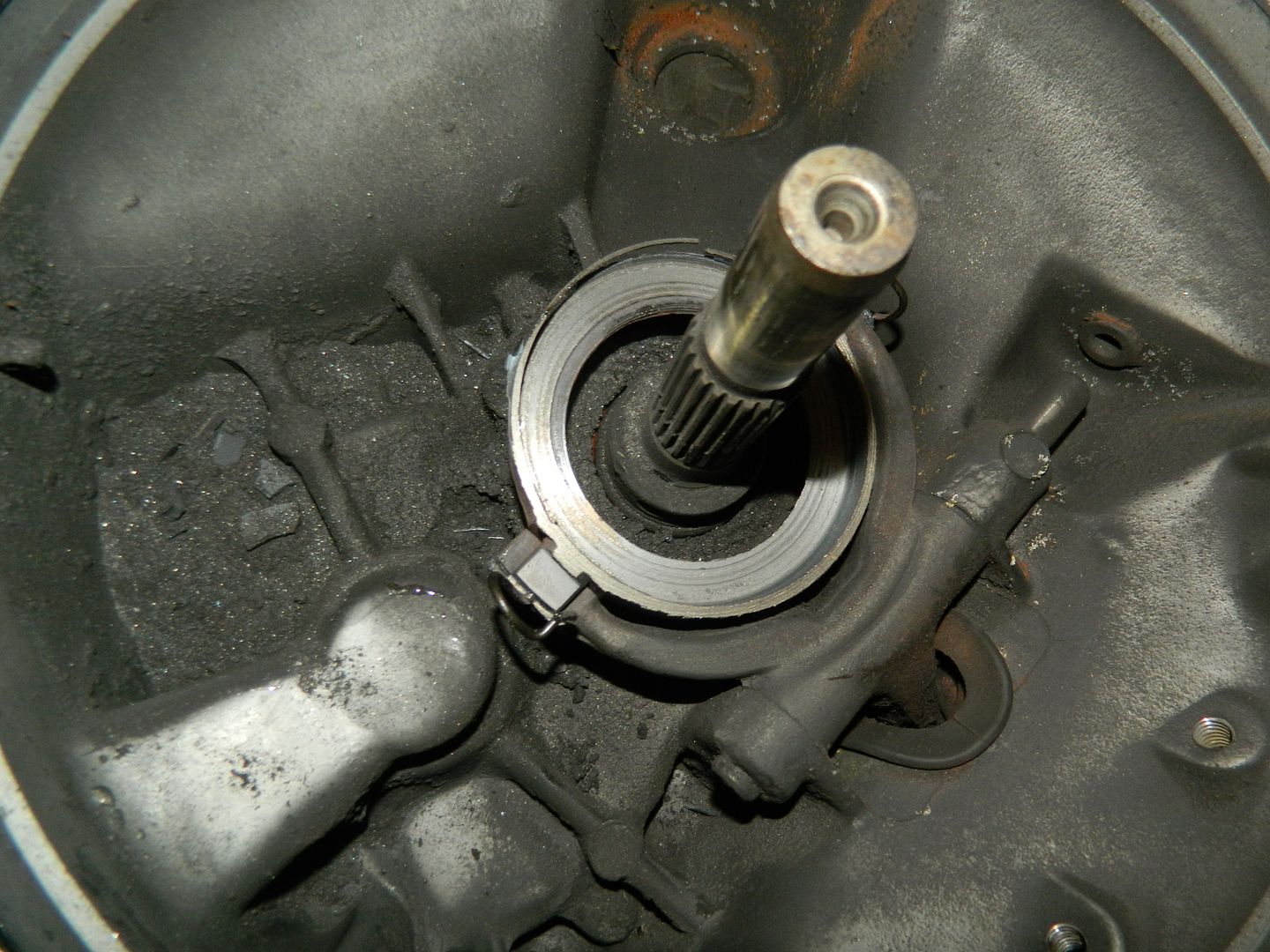

Got the engine out and the end housings off by Saturday evening. As suspected:   Release bearing completely shot. Spent ages trying to get the nut off the "stud down the hole", to no avail. Shining a torch down the hole revealed that it wasn't actually there. Wolseley Owners Club AGM today, so no progress. Will try and get some re-assembly done tomorrow. Chris. |

|

|

|

Post by charlypm on Mar 21, 2016 4:04:21 GMT

Mine looked almost exactly like yours  |

|

|

|

Post by Penguin45 on Mar 22, 2016 0:06:44 GMT

No, that's finished, Charly. Note how the flange on the clutch cover (steel) has worn away the cast iron around where the carbon used to sit. Note in the LOCI mag this month from Tony Wood says that he has some new CRBs available. He also has some part-worn ones if you wanted to make one of the roller bearing ones. Snoopy's got one in GLE now, which seemes to be working happily and no. 3 is about to go into the Red Dog. Hopefully the engine will be going back together tomorrow afternoon. Things got a bit complicated today, so engines didn't happen. Work - it's an absolute curse.  Chris. |

|

|

|

Post by bullyboy on Mar 22, 2016 8:14:56 GMT

Hi ALL

I have replaced mine as it was getting very low, just one question how long do these carbon bearing usually last?

Paul

|

|

|

|

Post by dave1800 on Mar 22, 2016 10:42:27 GMT

Hi Paul. I have had one last over 100K but that included lot of motorway driving. There are some obvious things you can do to extend the life including always taking the car out of gear when stopped in traffic and removing your foot from the clutch pedal, not slipping the clutch more than necessary when taking off, matching engine rpm with a blip of the throttle on downshifts and using the brakes rather than changing down a gear when safe to do so. Perhaps not so obvious is the need to ennsure the master and slave cylinders are in good order and not sticking. Any excess pressure in the line will hold the crb against the clutch harder and increase wear.

After that you are at the mercy of the quality of the carbon which has been variable in recent years. When replacing a crb I know it's too late now as you've done it then you should check the actuating arm to ensure it is not bent or worn and that the clips are located properly to ensure the carbon is absolutely parallel to the clutch cover.

One for Chris: given your experience with the roller crb would you recommend the mod to allow clutch adjustment for a carbon bearing?

regards

David

|

|

|

|

Post by bullyboy on Mar 22, 2016 12:25:15 GMT

Hi Paul. I have had one last over 100K but that included lot of motorway driving. There are some obvious things you can do to extend the life including always taking the car out of gear when stopped in traffic and removing your foot from the clutch pedal, not slipping the clutch more than necessary when taking off, matching engine rpm with a blip of the throttle on downshifts and using the brakes rather than changing down a gear when safe to do so. Perhaps not so obvious is the need to ennsure the master and slave cylinders are in good order and not sticking. Any excess pressure in the line will hold the crb against the clutch harder and increase wear. After that you are at the mercy of the quality of the carbon which has been variable in recent years. When replacing a crb I know it's too late now as you've done it then you should check the actuating arm to ensure it is not bent or worn and that the clips are located properly to ensure the carbon is absolutely parallel to the clutch cover. One for Chris: given your experience with the roller crb would you recommend the mod to allow clutch adjustment for a carbon bearing? regards David Thanks Dave for that, i have checked all is well and seems good, also that the clips are in the right place. I have have the slave/master cylinder refurbished with new st/st sleeves so they should be fine. So hopefully alls good. Paul |

|

|

|

Post by Penguin45 on Mar 23, 2016 0:09:43 GMT

Interesting. The new release bearing which I fitted when the Gold Seal engine went into Eugenie has only lasted about 9k miles. Everything was new, the release arm was free moving, yet it self destructed quite quickly.

By contrast, having now fitted the new clutch set into this one, I find that the release arm is virtually unmovable by hand. Mark assured me that he'd had the clutch done when he had the engine work done before the car went off the road, so again, it's only covered perhaps 8k miles. Strip down, clean and lube to come there then before the casing goes back on. This should fill the time whilst the new clips for the release bearing arrive - the current ones are scuffed due to the wear and I consider them to be untrustworthy.

Chris.

|

|

|

|

Post by Penguin45 on Mar 23, 2016 18:31:18 GMT

I have managed to remove the seized fork. 7/16" bolt on the outside of the casing has to go first, as it recesses into the shaft. A long 3/8" UNF bolt is needed to screw into the end of the shaft. A nut and washer is used to draw the bolt through in several stages.    What I believe BMC called a "make-up" tool.  Wear on the fork shaft, push rod hole and clevis pin. Not good. Chris. |

|

|

|

Post by tommydp on Mar 24, 2016 17:51:49 GMT

This has done 35 000 kms on my blue car. The carbon is 1.5 mms. A new one has 3 mms. Out of interest perhaps, just thought I'd share it. I'm putting in a new one while the engine is out. They're not long lasting. I'm sure quite a few 1800s were crushed due to the bearing giving up.  Tommy |

|