|

|

Post by snoopy11 on Apr 8, 2017 20:54:57 GMT

It all because you put something from the evil prince of darkness Mr Lucas within 100 ft of your car.

|

|

|

|

Post by 1800heap on Apr 8, 2017 23:06:44 GMT

Now, the hard questiion is this: The car is using an ETi100 electronic ignition, which uses the contact breakers as a switch, so why would the condenser failing still cause the car to run badly? My brain hurts.  Chris. Hi Chris Now I thought that the condensors job (basically a capacitor) was to prevent the car emitting nasty Radio frequency noises as you drive around. This RF is caused by the little spark from the contact breakers when they open l believe. You used to sometimes get it on the old AM radios as a nasty buzz that varys with engine speed! Capacitors depending on the type, only have a certain life even if you don't use them! This is because they have an electrolyte in them that drys out over time. Also high temperature shortens life. The higher the temp the shorter the life. This is usually factored in when smart fellows design electronic gear. It is also why smart IT people put air conditioning in communications cupboards! Sony elecyronic equipment of the 90's was notorious for bad caps! Caps can go two ways. They either change in Capacitance or develope internal resistance but usually both. They can develop an internal short circuit too. This can be seen in dead electronic equipment when they get hot and pop or get a big buldge on the top!! This resistance is bad as you have found out! If you still have the culprit condensor and you have a meter that measures resistance you can test it. Low resistance is bad. In fact anything except very high resistance is usually bad! What should happen on a good condensor when you connect your meter the resistance will climb well into the meg ohm range as the meter charges the cap. The faster it climbs the smaller the Capacitance. Bear in mind I haven't tested a good one to see, I am just going by general capacitor behavior. New old stock condensors are likley to have a short service life because of the above reasons! Nick |

|

|

|

Post by dave1800 on Apr 9, 2017 1:41:01 GMT

You are jinxed by ignition systems! I am not familiar with the ETI100 ignition system but it will be either the type that switches a power transistor or capacitor discharge type. If the former the contact breaker is usually left in place to aid transfer back to conventional ignition in the case of unit failure. If the ignition is of this type then simply removing and not replacing the condensor would have been sufficient. I am very surprised that the condensor would have failed as it would only be handling 12-14V instead of the normal 300-400V induced in the coil primary. In a conventional non electronic system the condensor limits the rate of rise and voltage in the coil primary when the CBs open. This prevents loss of energy by an excessive voltage across the open CB and the coil windings. It forms a LC (inductance-capacitance) circuit and is tuned to the coil inductance to optimise the energy transfer to the plugs. It is typically around 0.22ufd and formed from aluminium foil wrapped around mylar film (older units used waxed paper). This type of capacitor doesn't contain any electrolyte but can gradually break down through thermal stress and sparks burning away the foil. The early electronic units that utilised the CB as the trigger also incorporated a similar capacitor internally across the output transistor to protect the transistor from excessive voltages. Later units used avalanche diodes to protect the output transistor clamping the induced voltage to around 380-400V. More recently IGBTs (a form of transistor) have been used that have built in protction, again limiting the voltage to between 350-430V to protect the coil and IGBT. I am confused why you experienced overheating, normally misfiring should result in less heat. Unfortunately I am not convinced you have definitely cured the problem; it could be the internal unit capacitor that recovered after cooling down or the output transistor on its way out - or the coil. As 1800heap suggested check whether the condensor is showing any leakage (resistance) as if it is this would have screwed up the CB triggering. If the unit is a capacitor discharge type again this could be an internal capacitor issue. Sorry if this isn't good news but I fear your ignition saga is an ongoing story! regards David Now, the hard questiion is this: The car is using an ETi100 electronic ignition, which uses the contact breakers as a switch, so why would the condenser failing still cause the car to run badly? My brain hurts.  Chris. |

|

|

|

Post by 1800heap on Apr 9, 2017 7:04:08 GMT

Unfortunately for you Chris David may well be right about your fault still being present. I have been enlightened about the main reason for the condensor thanks David. I have thought it was for reducing RF for about 20 years!! It probably helps with the service life of the contacts as well. Makes sence to use foil type caps for better service life. I thought for some reason the condensors had PCB's in them (Polychlorinated biphenyls. A nasty chemical!) not sure why! Bad memory strikes again!

As David said they will still suffer in the heat. Incase you didn't realise the coil is powered with 12 volts but when the magnetic field colapses as the contacts open, voltage is induced in the opposite direction in the primary winding as well as the secondary. This voltage is quite high and is why you get a shock sometimes when playing around with the primary side of the coil. Also if you are a silly fellow like me and forget to ground your plug when testing for sparks a nasty shock from the secondary! Much higher voltage!

Nick

|

|

|

|

|

|

Post by dave1800 on Apr 9, 2017 8:43:17 GMT

Nick

Capacitors are used to reduce RF and power line noise. It used to be common to see one across the dynamo and also from the coil power terminal to ground as well as across radio power feeds often as part of a suppressor arrangement. The one inside the distributor will also reduce RF noise as well as peforming its primary function.

David

|

|

|

|

Post by 1800heap on Apr 9, 2017 9:52:12 GMT

All good David what I ment was I thought the primary function was RF didn't consider anything else. You have in fact enlightened me as I said. Happy to be enlightened I am far from an expert!

Nick

|

|

|

|

Post by dave1800 on Apr 9, 2017 11:48:50 GMT

I wish I had the internet 50 years ago, I have learned so much in the last ten years and now realise some of what I thought I knew was wrong or incomplete. I remember the days when an oily Haynes manual was all you had to refer to do everything. It's great to be able to have access to so much information.

David

|

|

|

|

Post by peppib on Apr 9, 2017 13:56:52 GMT

Thats why I stick to points, A well maintained points set up is less hassle than some electronic setups ( in my humble opinion, I might add )

You will always get a points system sorted in an emergency ?

Worse comes to worse, a dizzy in the boot all fitted up with points, condensor etc ready to fit is a good thing...

Good luck with it   +1. I just don't understand electronic devices which is why I avoid them  |

|

|

|

Post by Penguin45 on Apr 9, 2017 18:59:10 GMT

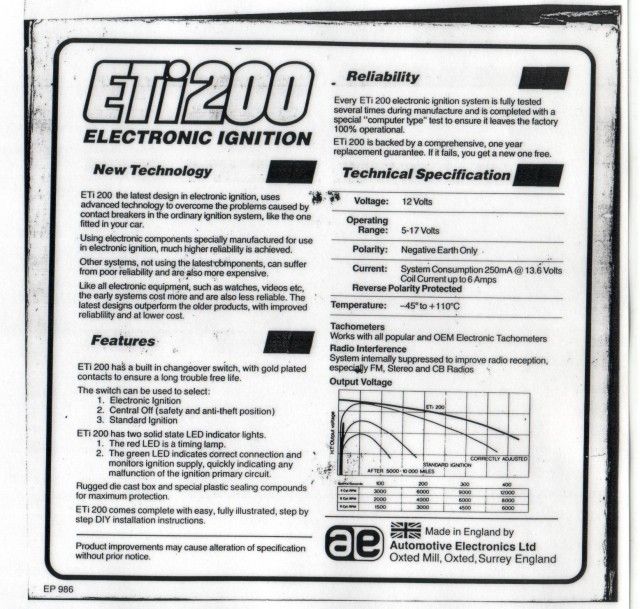

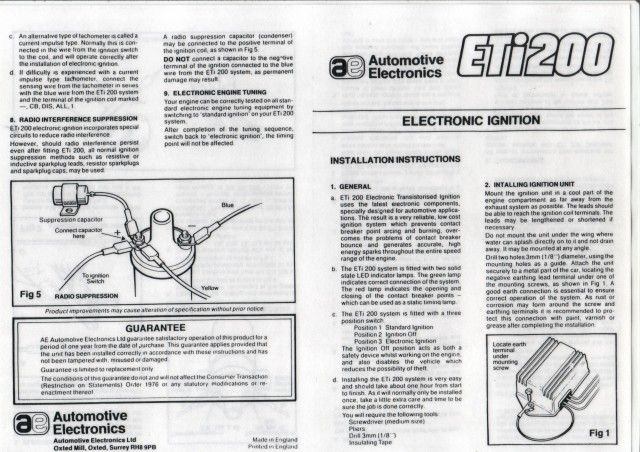

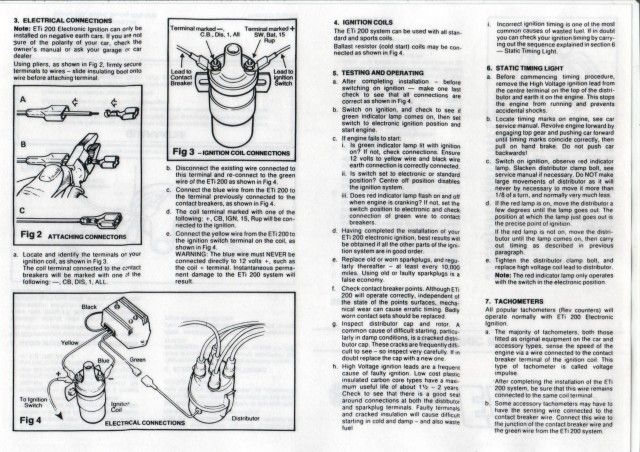

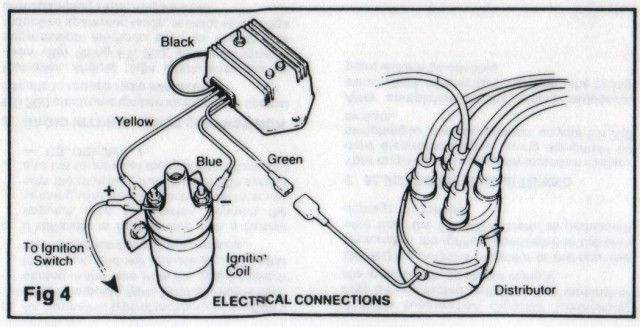

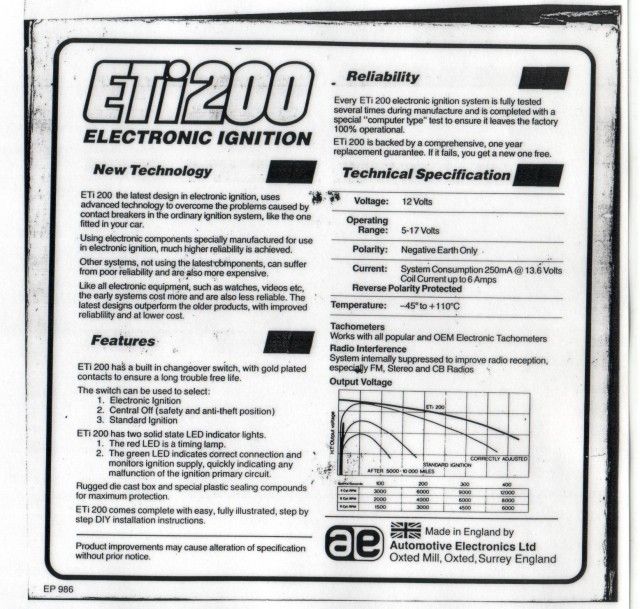

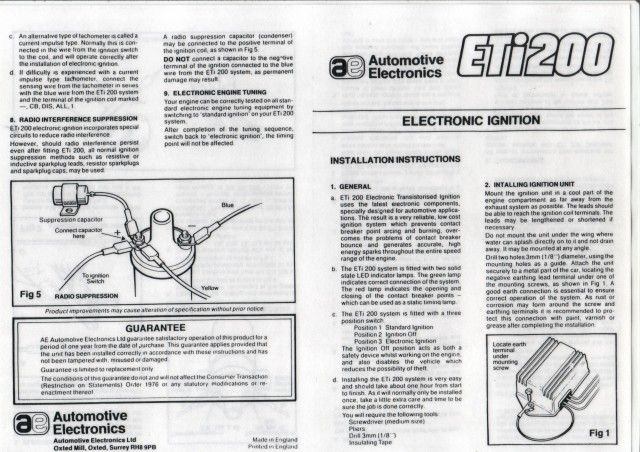

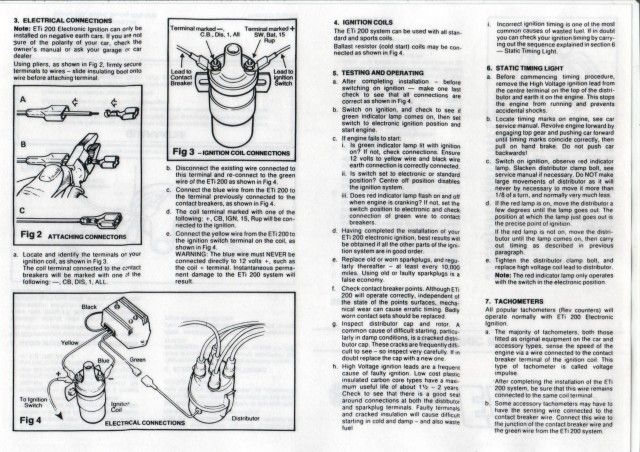

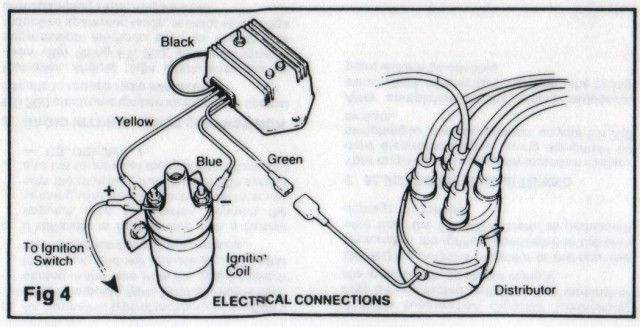

Interesting responses, thanks to all. Except Snoopy. Idiot.  As Dave1800 has observed, there are no limits to the information which can be dug up on the internet. So for your information, delectation and entertainment, here are the instructions for the Automotive Electronics ETi200. This is the same unit with addition of a switch allowing you to flick between electric and points ignition, as well as an off position.     I was none the wiser, but better informed. I have also been playing with my insulation tester. This is normally used to test electrical safety in domestic appliances and can pass 500vDC or even 1000vDC through electric objects. What better then than to test condensers? The one removed from the car yesterday showed a reading to earth of 2.8MΏ @ 1000vDC. A brand new condenser showed ∞Ὠ @ 1000vDC. The first reading is effectively a high voltage short circuit - the path to earth will be easier with the higher voltage (30Kv?) of the ignition. Also worth noting that the faulty condenser showed no reading to earth when tested with a standard 9vDC multimeter. Chris. |

|

|

|

Post by 1800heap on Apr 9, 2017 22:33:45 GMT

Hi chris

Be a bit carefull what you use your insulation tester on. Caps have a rated voltage and you may damage them by zapping them with a 1000v insulation test. Not sure what condensors are rated at. David said they run at about 400 volts so may only be rated as an example at say 800v. If you insulation test to 1000v you could breakdown the insulation and cause premature failure! If the cap is rated at 2000v then no problem using a 1000v insulation test. Definitely don't test any electronic devices with it unless they are destined for the bin!!

Nick

|

|

|

|

Post by 1800heap on Apr 9, 2017 23:03:42 GMT

A quick search reveals insulation test ok at 500v and best not to test any highter as you may damage the condensor. Anything under 40 meg ohms the condensor is bad so it said.

Nick

|

|

|

|

Post by Penguin45 on Apr 9, 2017 23:05:55 GMT

Mmm - yes and no - current is minimal although voltage is high (ish). For appliance testing, 500v is standard and a requirement if you are doing the job properly and issuing a signed certificate. Paper trails and all that regulatory tat, you know. As for a £3 Chinese fake condenser; who cares? I found out what I wanted to know, which was that the unit removed had developed a pathway to earth, which a new £3 Chinese fake condenser hadn't. I suppose the proviso will be "yet". Snoopy's comment about Lucas is really rather unfair. Their original product was absolutely fine, it's the modern stuff coming through now badged up as Lucas which is the real problem.

I'm assuming that the condenser had already failed or was in a failing state prior to the switch to the electronic unit. Not unreasonable as it came out of one of the spares boxes in order to give Gordon his own distributor back. She seems happy enough at the moment, so fingers crossed.

Chris.

|

|

|

|

Post by dave1800 on Apr 10, 2017 3:32:07 GMT

Interesting results from the capacitor testing. With the electronic unit the points capacitor will only be subjected to the vehicle's 13.8V or so and not any inductive high voltage load. They typically switched around 100ma through the points to keep them clean. However, the fact that it showed a resistance albeit quite high at 500v confirms the capacitor is faulty and what it was doing at 100C or so inside a vibrating distributor is unknown.

Testing with an insulation tester at 500v is worthwhile because a points capacitor would be expected to have a 600V or more specification to withstand the 400v or so during normal running.

Where I used to work, the whole electrical system was tested with an insulation tester as part of the regs each year. We were asked to ensure all equipment was left plugged in. The first year, my section's fax /scanner wouldn't work the next day, coincidence? It took about about a month to be fixed which was a real pain and very inconvenient. The same thing happened twelve months later. While the insulation withstood the test clearly some of the components were not isolated from the power source, maybe due to the standby circuitry? Just a warning.

There is an interesting question here given the high failure rate of many modern automobile capacitors. If as they fail the capacitance diminishes then the induced voltage on the coil primary will rise above its designed level. This could in theory lead to breakdown of the capacitor and also the coil insulation leading to premature failure. I have seen videos on Youtube showing such capacitor failing in electronic circuits as the foil is gradually eaten away in modern LED lamp drivers.

This is also a reminder to keep the distributor cap and all plug leads and plugs in good condition. Any increase in resistance in the coil secondary circuit from bad plug leads etc will also allow the primary voltage across the condensor to rise and possibly cause damage.

Testing for a spark with other than a proper spark tester can quickly weaken an electronic unit as all the energy is dissipated across a few microns of silicon inside the output transistor. I often see videos of mechanics still ignoring this advice putting customer's ECUs (or coil packs depending on the design) at risk maybe a few months down the line. I guess they don't care as they aren't paying the big repair bills!

David

|

|

|

|

Post by 1800heap on Apr 10, 2017 9:19:57 GMT

I found out what I wanted to know, which was that the unit removed had developed a pathway to earth, which a new £3 Chinese fake condenser didn't. Chris. The Chinese condensor probably hasn't got anything inside it, thats why it passed! I wonder sometimes how many have a chuckle to themselves when the take our money! Its your megger tester you go for it!! Not trying to tell a sparky how to use or where to put his megga tester all good ha ha. You may be confusing killing someone with killing a cap though!! Nick |

|