|

|

Post by Penguin45 on Jul 26, 2015 20:19:31 GMT

Spent most of today in Bolton getting soaked, trying to sort out the recalcitrant GLE. Car's run nicely, apart from a rather worrying drop in oil pressure as the car drops down to idle. Plenty of oil, so will have to be investigated more fully.

Chris.

|

|

|

|

Post by Penguin45 on Jul 30, 2015 15:52:38 GMT

Been out working from the car during this week. It started to run very rough in Otley today. As I pulled away from a customers house, there was a metallic clang. The shiny thing lying in the road turned out to be a cover from one of the K&N filters. Put it back on with a nut from the other cover, so they're on with one each. Probably leaking air, so it'll be running lean. This was followed two hours later by the clutch plate collapsing and a tow home by the nice RAC man. So, engine out to come. I'm a bit miffed, as that was a completely new clutch kit when this engine went in, so it's probably only done about 7,000 miles. Not really in a very good place at the moment. Chris. |

|

|

|

Post by Nick RS on Jul 30, 2015 16:21:34 GMT

Chris, Sorry to hear of that, you don't seem to be having a good run of luck with the cars lately. That's probably the same RAC van that visited me on the Otley Road coming out of Leeds last year.

hope the investigation and fix isn't too traumatic.

Nick

|

|

|

|

Post by dave1800 on Jul 31, 2015 2:28:58 GMT

So sorry Chris. I'm sure you have other things you would rather be doing with your time and cash. It may be worth trying to establish the cause of the low oil pressure at idle when hot while the lump is out even though that's more work. Do you recall what brand of clutch plate, cover etc was fitted? Were there any warnings at all or just the catastrophic failure? Things will get better  regards David |

|

|

|

Post by Penguin45 on Sept 25, 2015 19:08:51 GMT

She's finally in the garage. Snoopy's coming over tomorrow. Oil draining as I type.

So - clutch, thrust washers, valve stem seals and oil pressure to look at. I was pretty sure that the oil pump was new when I looked before fitting the engine to the box. Relief valve kit is pennies, so might do that anyway.

Chris.

|

|

|

|

Post by snoopy11 on Sept 25, 2015 22:04:00 GMT

She's finally in the garage. Snoopy's coming over tomorrow. Oil draining as I type. So - clutch, thrust washers, valve stem seals and oil pressure to look at. I was pretty sure that the oil pump was new when I looked before fitting the engine to the box. Relief valve kit is pennies, so might do that anyway. Chris. I hope this clutch is a tad easier than the matiz. |

|

|

|

Post by Penguin45 on Sept 25, 2015 22:45:22 GMT

If we can pull the engine and split it off the gearbox, I'll be happy with that as a day's progress.

Chris.

|

|

|

|

Post by peppib on Sept 26, 2015 7:16:25 GMT

Good luck. Still have nightmares (and sore bits) from when I did mine. Worst problem was finding a spanner to undo that huge nut that has to come off. Eventually borrowed on from a guy who was restoring a fire engine!

|

|

|

|

Post by tommydp on Sept 26, 2015 8:07:18 GMT

Best of luck! Looking forward to updates.

Did you find the cause of the low oil pressure, Chris? It could be 15 - 25 at slow idle.

Regards, Tommy

|

|

|

|

Post by dave1800 on Sept 26, 2015 11:03:40 GMT

Oil pressure relief valve worth replacing as you say it is low cost and the spring weakens over time. The consensus seems to be that the oil pump is pretty robust and is not normally the primary cause of low oil pressure (but you can examine the inner surfaces quite easily just to be sure after all the work getting there). Do you have the original Wolseley electric sender, if so can you calibrate it to make sure you really do have an issue and not just a sender gone out of spec - they weren't too accurate when new I recall (sorry should have mentioned earlier but you are probably 10 steps ahead of me anyway!).

If you find thrust bearing wear worth a quick look at the main and big end shells as they are the main cause of loss of pressure.

Good luck; another fun weekend.

Regards

David

|

|

|

|

Post by Nick RS on Sept 26, 2015 14:35:04 GMT

I think Penguin and Snoopy will be like one of the Apollo missions on the dark side of the moon. Radio silence until they come out the other side.

Nick

|

|

|

|

Post by Penguin45 on Sept 27, 2015 0:05:48 GMT

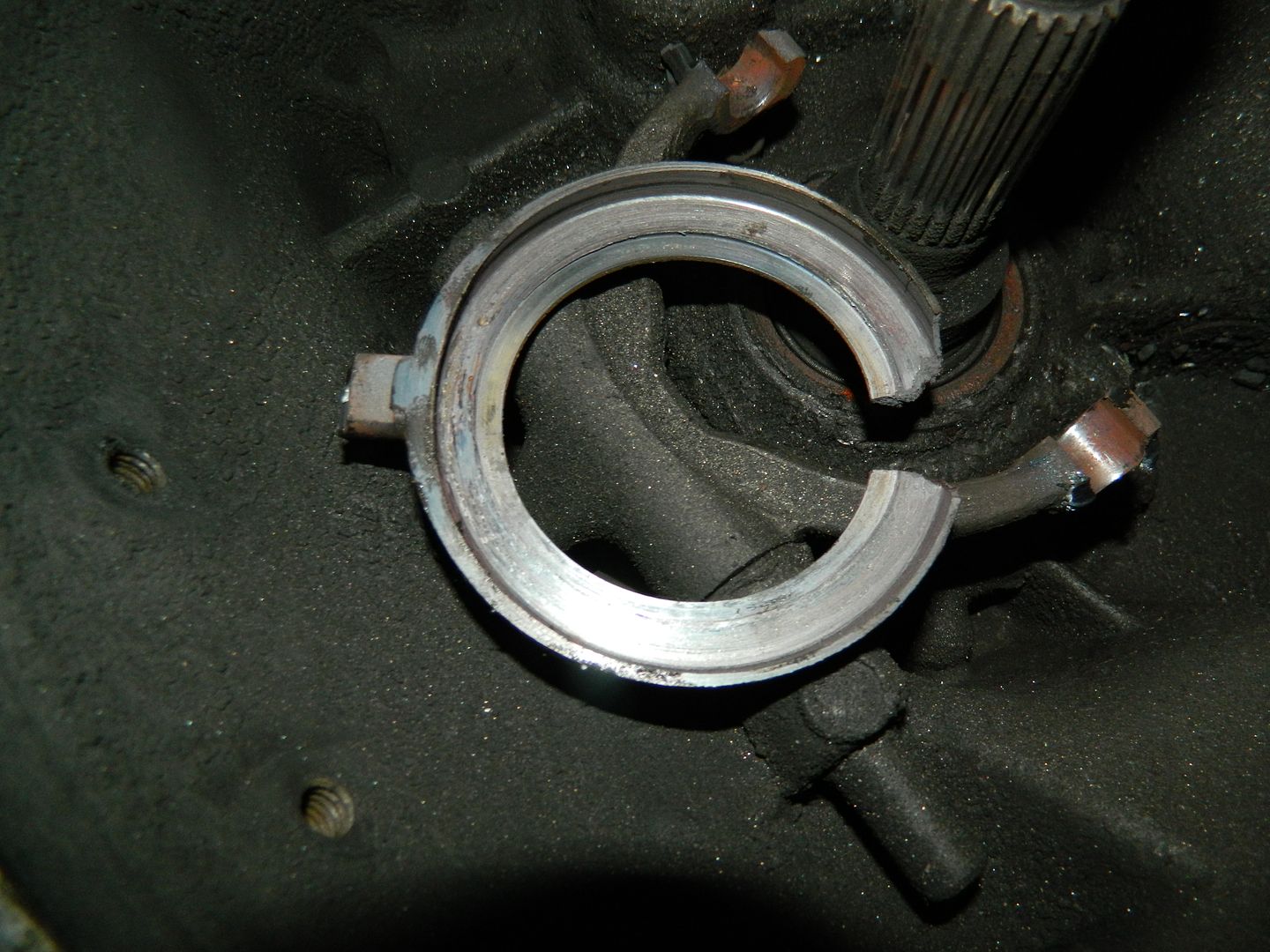

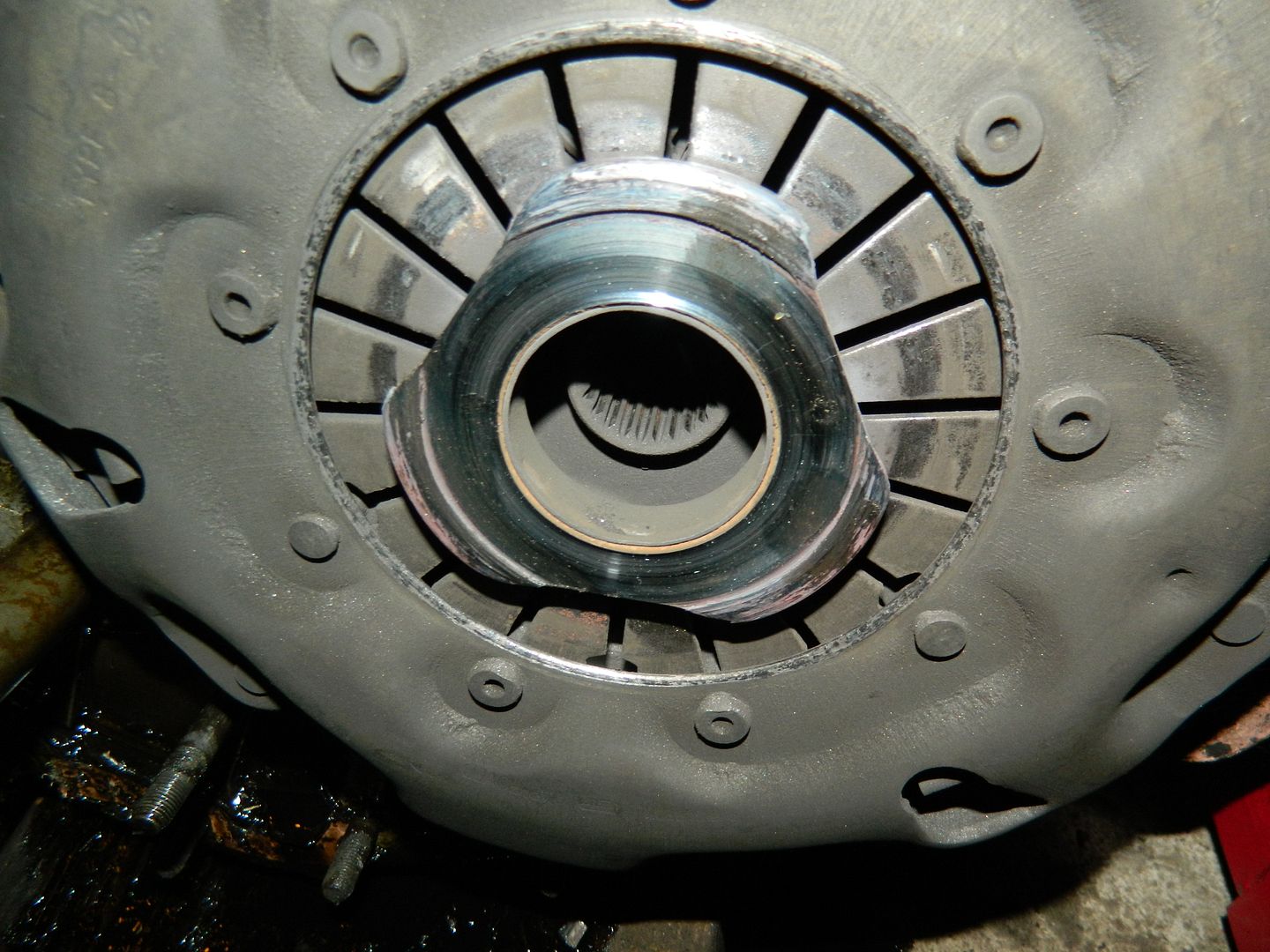

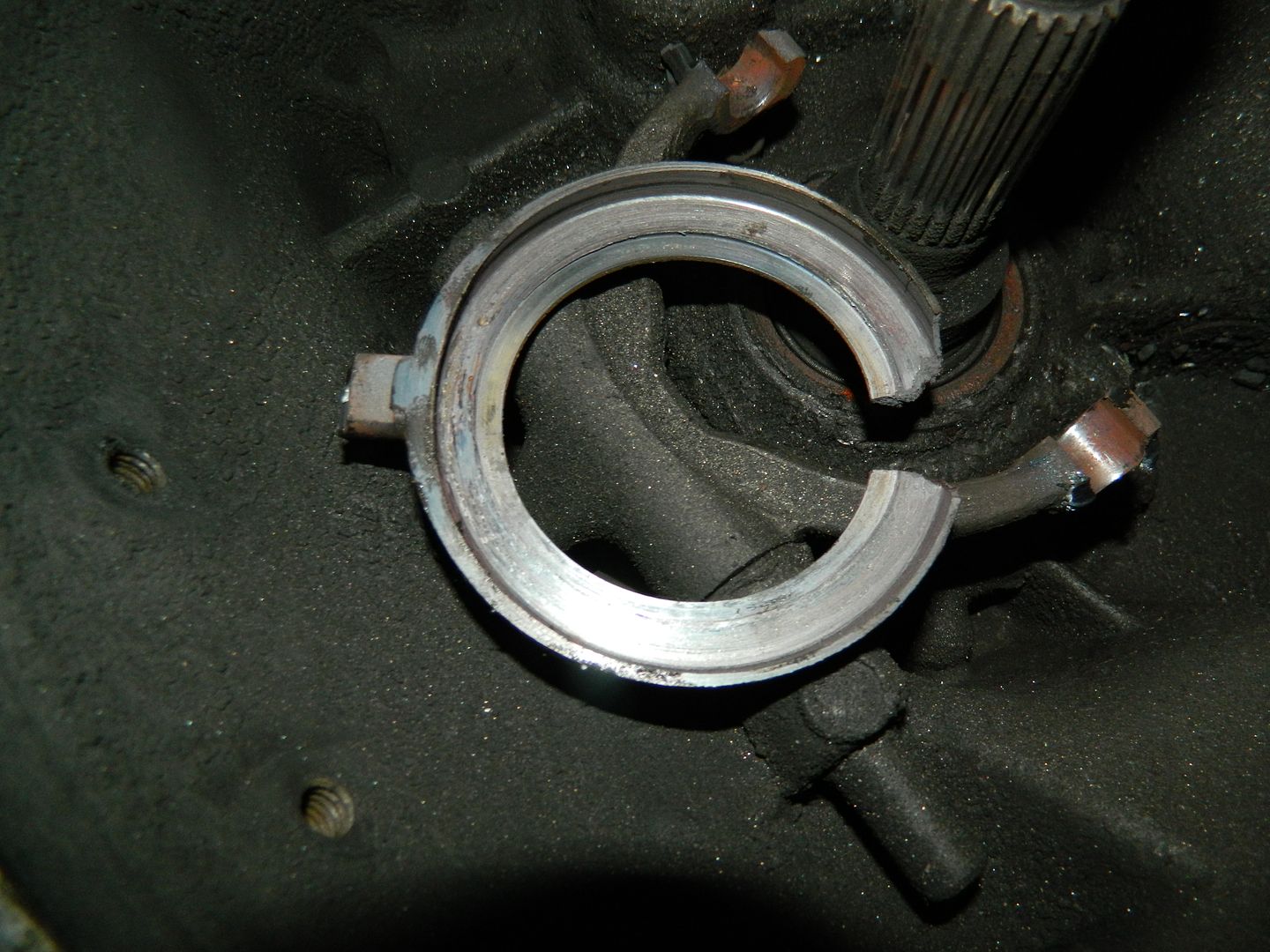

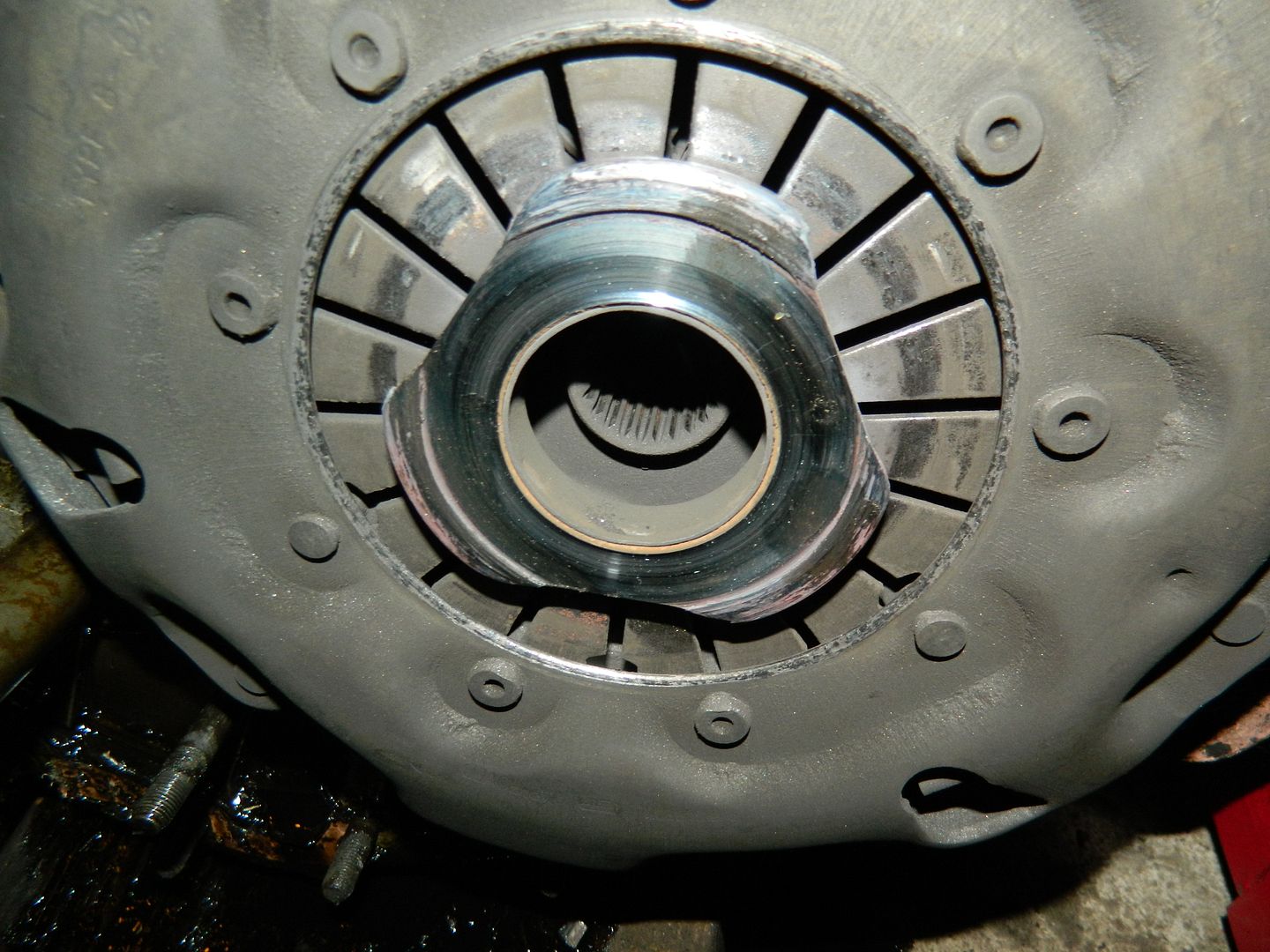

It would be fair to say that we've been a bit busy.......  The power unit is out and is split into the major assemblies. It's been a complete and total cow and Mark and I finished up completely filthy. Good old fashioned "Fun for Boys" then. It really was extremely reluctant to hand over 450lbs of cast iron. Anyway, we did it and managed to pull things apart. My primary concern was what had happened with the clutch, so the housing was eventually removed. I was expecting to find a broken diaphragm spring, but found this instead.   Broken release bearing. The carbon apppears to have shattered and it's then run metal on metal until it's worn through. Honestly, you couldn't feel it through the clutch pedal. The first clue I got was when it went "Ting!" and changing down became very difficult.  Bearing surface on the diaphragm is deeply grooved and is therefore scrap. They've only done about 7k miles. Disappointing. In answer to a question from David earlier I *think* this was an AP old stock clutch kit. Anyway, it'll all be replaced. Taking the head off the engine revealed another surprise.  Head gasket gone between 2 + 3. Astonished - the car was running really nicely, no smoke and even the plugs are a good colour. So, that will have to be investigated. The engine has been taken off the gearbox. The rear joint was soaked in oil and Mark commented that the bolts and studs didn't seem to be particularly tight. Having had a bit of a tinker, I'm inclined to agree, so that may have been the cause of much of the oil loss. Oddly enough, the O ring from the oil pump in the flange seemed to have shrunk significantly, so that may have been adding to the leakage and the oil pressure problem at low revs. The good news bit is that there is virtually no fore and aft play in the crank, so the thrust washers are probably fine. Will do some proper measuring tomorrow. An end lug on the exhaust manifold has snapped off (and has been for a while, looking at the soot) so that will need to be dealt with. The engine bay itself will need some attention as there are a few areas of rust that need some attention and there is definitely something wrong in the n/s bottom corner where the towing loop fits. Hammer and MIG may be required. Apart from that, it's fine. Thanks to Mark for what turned into a pretty mega days work - really appreciated. Chris. |

|

|

|

Post by dave1800 on Sept 27, 2015 0:39:44 GMT

So now we know why you've been advertising for old clutch release bearings  . Amazing there was no squealing or clutch engagement near the floor. I think you need to investigate the cause eg too much residual pressure in the clutch hydraulics, or could just be a rubbish crb, difficult to detect the latter in it's absence! A good quality reinforced head gasket (Payen?) is clearly needed. Maybe the head wasn't torqued down sufficiently, refer to earlier discussions on head torque dry v wet and when to use new studs. As you say the lack of crank movement back and forth is a good sign re the thrust washers. Good hunting! regards David |

|

|

|

Post by Penguin45 on Sept 27, 2015 12:04:11 GMT

I need to check that the head is true. Payen gasket set - definitely. The oil gauge was changed to a capillary type (W6). Will need to find new engine mounts for the cross bar mounting. These are apparently from a Land Rover. The small rubber (Mini exhaust bobbin?) has ripped apart and one of the LR one's is delaminating.

Little shopping list being created!

Chris.

|

|

|

|

Post by dave1800 on Sept 27, 2015 12:13:08 GMT

Worth a check the block as well I guess. Probably not an issue just a bad gasket with luck. Feeling tired? You should get a job painting the Forth bridge.  David |

|