wolseley1800

Member

Posts: 127

Attribute: The Voice of Doom!

|

Post by wolseley1800 on Sept 22, 2016 23:01:40 GMT

Would only grease splines, preferably with an anti seizure type. Why make life harder. Maybe worth reminding people to first use a thick flat washer to tighten the hub then remove it and tighten against the cone. If there is no wear in the splines then it should be assembled in the same position (so mark it), however is there is wear a different position can be tried. If this does not cure the problem it may be that the preload on the wheel bearings is incorrect and this is critical. The quote figure is 0-4 thou but in practice this is difficult to measure. You should just be able to feel it. I believe that the shims for the ball joints are the correct diameter to help obtain the correct clearance if it is too tight. The advice in the w/s manual is to tighten to allow the split pin to be fitted to the next hole, not back off? That's what you indicated in an earlier post. Am I misunderstanding? Use of Loctite on the splines and hub nut worth considering. David Was thinking about the squeak on way t'house. Since cone washers are new could be the hub worn or as I suggested, may just need torquing up. No not F.T. but with a proper wrench (wrench not wench). I got the socket and wrench if needed. For those that do not know, the correct torque on the hub is vital. The MOT tester should try to fail it on loose wheel bearing. Trick is to over-torque then release and put correct on. this way you have a better chance of settling it all down. If split pin hole does not line up it is better to undo rather then tighten. Another point is not to grease the stubshaft threads as this can give a false reading. Degrease it and nut and fit dry. Sorry to preach to the converted but some one may thank me as the split cones are rarer than hens teeth. |

|

|

|

Post by dave1800 on Sept 23, 2016 1:26:49 GMT

You may well be right, but that advice was given by a manager for a BL main agent. Not sure if it was from their experience or covered in a service bulletin. Having driven crabs for hundreds of thousands of miles I never again suffered hub problems after using Loctite and tightening to the next hole, so I am just relaying what worked for me. I believe BMC/BL never truly acknowledged there was a problem so didn't redesign the hub. David Would only grease splines, preferably with an anti seizure type. Why make life harder. Use of Loctite on the splines and hub nut worth considering. David |

|

wolseley1800

Member

Posts: 127

Attribute: The Voice of Doom!

|

Post by wolseley1800 on Sept 24, 2016 20:27:42 GMT

Ok, time and experience count so will consider this next time.

As for the service bulletin, nothing in the ones I have.

|

|

|

|

Post by Penguin45 on Sept 25, 2016 23:06:19 GMT

Wheel bearing done. Exactly and precisely as per the book. The only thing I could find wrong when I stripped it was that the tension spring from the outboard bearing seal had popped off. More to follow fairly soon.

Chris.

|

|

|

|

Post by Penguin45 on Oct 13, 2016 23:30:08 GMT

The wheel bearing write up has been over in Technical for a while now, if you want to know how it's done.

Anyway, Sunday saw the purchase of an offside Hadrian sill from the bay of evil things for a reasonable sum. Trouble is, it was "collection only" in Northfleet in Kent. I did ask Ahctog1 if he could collect it for me before I hit "Buy It Now", thinking I'll pick it up at a show next Spring. Not only did he pick it up for me Monday evening, he said he'd be in Catterick on Wednesday! Superstar! Now that's only a bit over an hour away, so I set off to pick it up late Wednesday afternoon. Nice little trundle up the A1 to the roadworks. The junction to Catterick isn't there anymore...... Satnav has nervous breakdown. Spotted a new junction about a mile up the road, satnav wakes up, took the junction and the alternative route now doesn't exist anymore either. Turned round, ran back to the junction, found a second roundabout, ran back down the A1 to take the southbound Catterick junction, missed what little signage there was and went for a grand tour of north Yorkshire. It's now pitch dark and I'm creeping round a bunch of country lanes with the headlights on in a dynamo car with the charging light flickering just a little more frequently as time passed. I got there eventually. Ahctog had a similar experience..... The cheerful locals at the pub weren't much help, as they explained that the road layout was changing week by week! Turned all the electrics off and left the car idling whilst wew sorted out the sill and had to head straight back south again. Fortunatley a good blast down the A1 put some charge back in the battery and I got home safely.

Big thanks to Barry (and Anita) as the sill must have been a major inconvenience on their trip north. I can hopefully do a better job on PeppiB's other sill now.

Mick and I finished off the little green monster this evening, so that can come out of the garage now and go for it's re-test and PeppiB can bring UMO back down during next week.

Apart from that, it's been really quiet.

Chris.

|

|

|

|

Post by Penguin45 on Oct 27, 2016 23:42:14 GMT

Popped up to York on Wednesday afternoon and collected a bonnet which has a sound front edge and hasn't been sat on by an elephant. It's just blue. And - a clock. The little miniature rectangular clock which fits into the MkII faux wood trim above the dashboard and can't be read by the driver anyway. Mmmm - nice. Oh, and a brand new grill badge and escutcheon. Also very nice.

Wonder when I'll get a chance to fit them?

Chris.

|

|

|

|

Post by dave1800 on Oct 27, 2016 23:51:33 GMT

You can fit the clock when you have the time  |

|

|

|

Post by Penguin45 on Oct 28, 2016 20:18:01 GMT

You can fit the clock when you have the time  It looks like there's another pair of sills heading my way once PeppiB's car has gone home. Possibly with wings and valance to do as well..... Chris. |

|

|

|

Post by Penguin45 on Apr 6, 2017 22:51:45 GMT

Gosh. October for the last write up. She's been absolutely fine and getting some regular use. Unfortunately, the MoT date has slipped past me and she's now in the garage. Second exhaust box has had to be welded up and it all needs new suport bobbins. I've bought polyurethane ones in the hope that they will last longer than two years. I'll get some pics over the next day or so.

Test on Monday.

Chris.

|

|

|

|

Post by Penguin45 on Apr 7, 2017 19:09:16 GMT

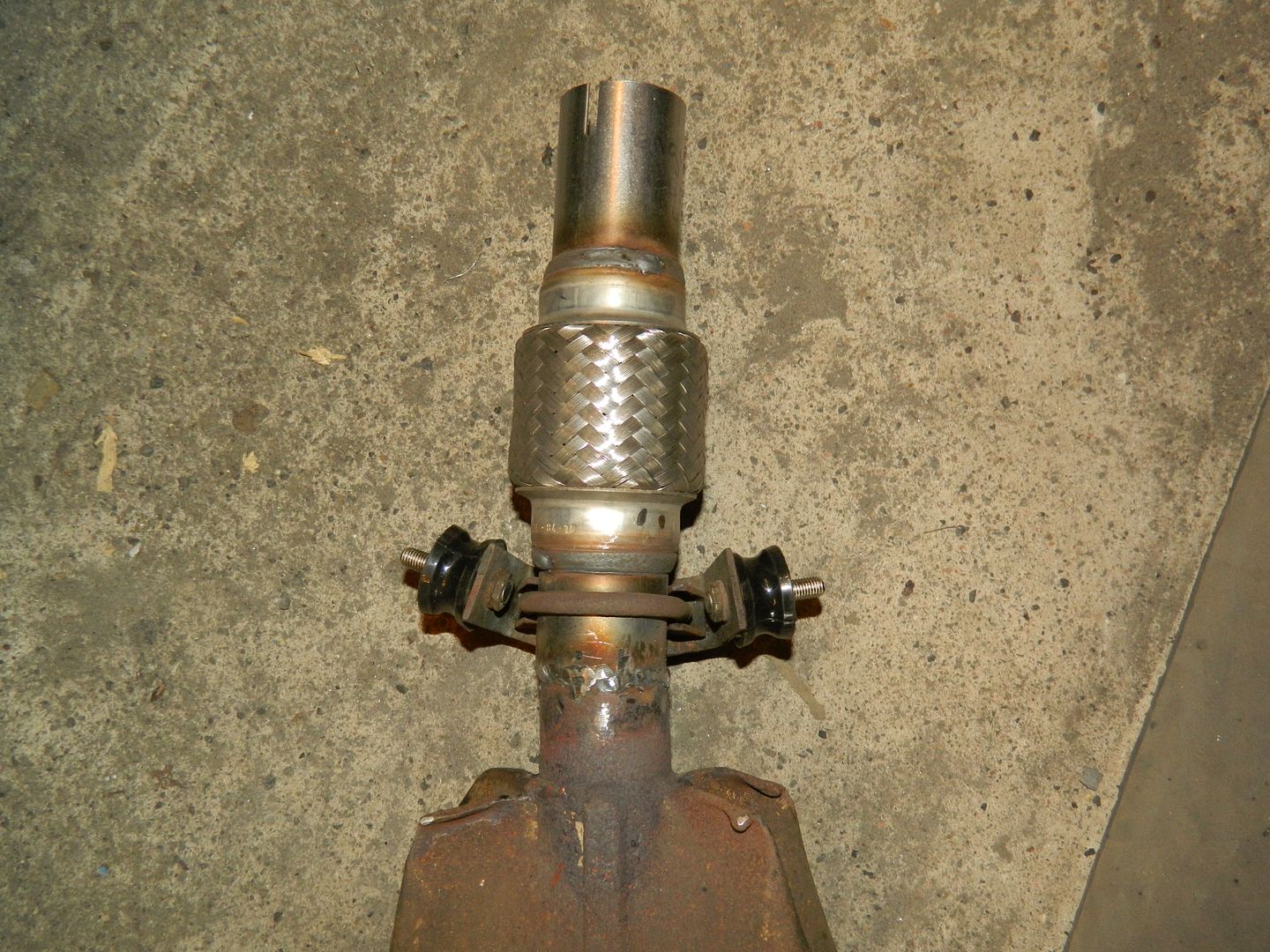

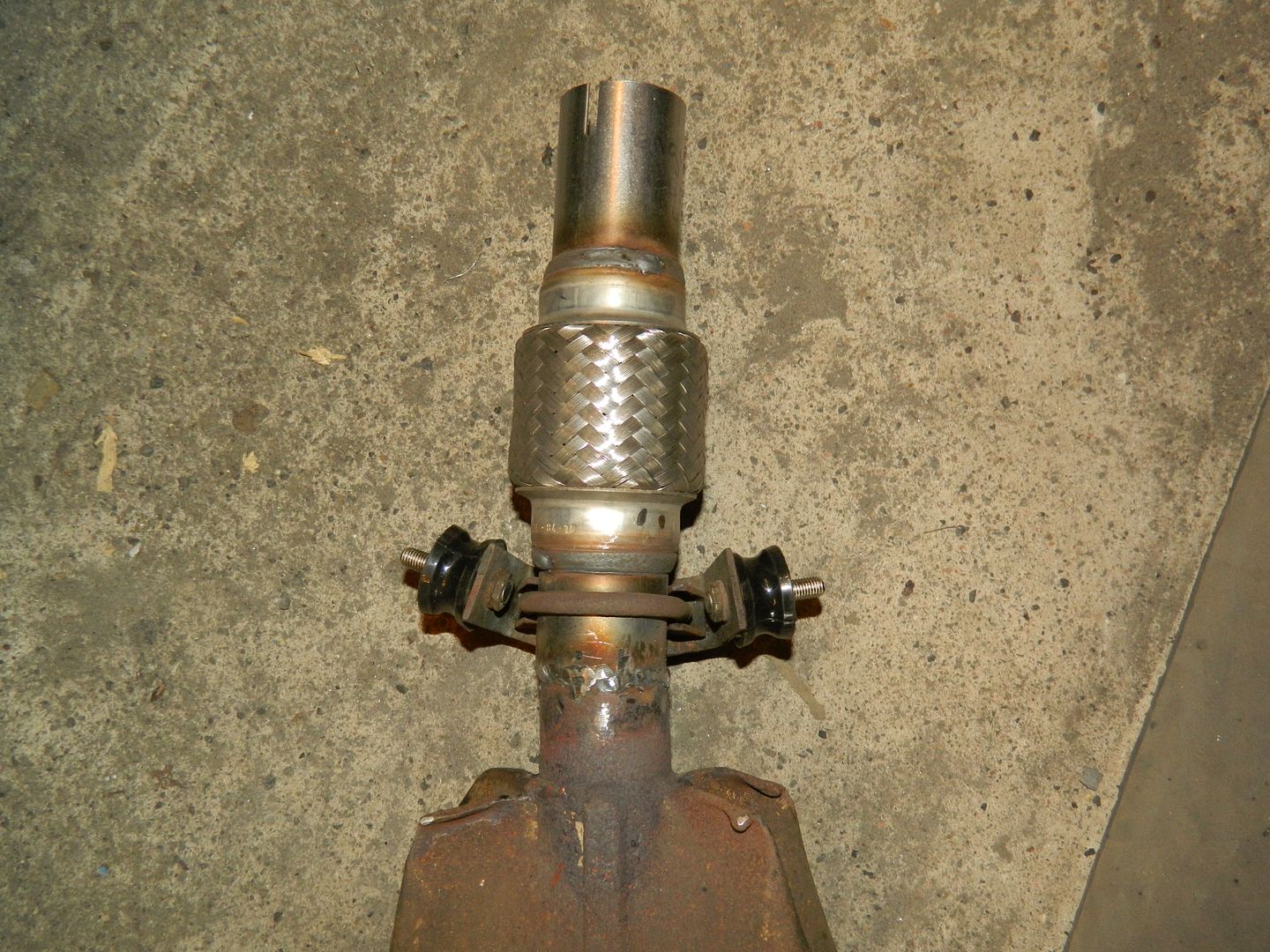

Second box welded up and painted with high temperature silver paint.  Centre support clamp. All rubber bobbins replaced with poly ones.  Inlet pipe cut back, then extended in order to move the joint into the front pipe frowards.  Like that. Front support bracket proved to have a bolt missing, so that was replaced. Manifold to pipe joint is a well known pain in the behind. There are four components plus the nuts and bolts to be arranged around the joint and it can take for ever. I had a minor epiphany and tack welded the bolts to one of the outer clamp halves. Assembly then literally took 5 minutes. I suspect that it could even be done one-handed. Chris. |

|

|

|

Post by dave1800 on Apr 8, 2017 3:09:53 GMT

Good luck wth the MOT! It will be interesting to see whether the pu bobbins introduce any more noise, at least they should last a lot longer. The trick with the manifold to exhaust pipe clamp was well known by BMC agents in the sixties and seventies and was the first thing I did after fighting that joint a few times! David Centre support clamp. All rubber bobbins replaced with poly ones. Manifold to pipe joint is a well known pain in the behind. There are four components plus the nuts and bolts to be arranged around the joint and it can take for ever. I had a minor epiphany and tack welded the bolts to one of the outer clamp halves. Assembly then literally took 5 minutes. I suspect that it could even be done one-handed. Chris. |

|

|

|

Post by peppib on Apr 8, 2017 7:24:30 GMT

Nice work.

I couldn't weld Mo's box so she sports one from a Vauxhall Corsa - cheap, a good fit and it does the job, although sounds different

|

|

|

|

Post by Penguin45 on Apr 10, 2017 13:54:33 GMT

She's just passed the MoT test without even an advisory.  Chris. |

|

|

|

Post by peppib on Apr 10, 2017 15:45:52 GMT

Well done

Dave

|

|

|

|

Post by indianajones on Apr 18, 2017 4:56:44 GMT

Nice work _b

-Andrew

|

|

Maybe worth reminding people to first use a thick flat washer to tighten the hub then remove it and tighten against the cone. If there is no wear in the splines then it should be assembled in the same position (so mark it), however is there is wear a different position can be tried.

Maybe worth reminding people to first use a thick flat washer to tighten the hub then remove it and tighten against the cone. If there is no wear in the splines then it should be assembled in the same position (so mark it), however is there is wear a different position can be tried.  Was thinking about the squeak on way t'house. Since cone washers are new could be the hub worn or as I suggested, may just need torquing up. No not F.T. but with a proper wrench (wrench not wench). I got the socket and wrench if needed.

Was thinking about the squeak on way t'house. Since cone washers are new could be the hub worn or as I suggested, may just need torquing up. No not F.T. but with a proper wrench (wrench not wench). I got the socket and wrench if needed.