|

|

Post by dave1800 on Mar 22, 2014 1:06:27 GMT

I had a first hand lesson yesterday of why it is important that a car's integrity is maintained for your safety. A new Mazda 2 failed to stop at a junction and rammed the side of my 2.5 ton SUV hitting it so hard it was knocked sideways. Fortunately I was only travelling at walking pace and no one was hurt. The strong bodywork prevented any intrusion. I though afterwards about what would have happened if my vehicle had been old with rusty sills and door panels as may be the case with some Landcrabs putting you and your loved ones at risk. The 1800 has the benefit of high rigidity and deep sills which may help considerably in a side shunt as long as the metal is sound. Chris and others, your pictures here of what you have found and how you have dealt with them are a revelation. I hope they act as a warning for those possibly taking short cuts. No matter how careful you are you never know when an accident may occur that is not your fault. Mine occurred in a shopping mall car park! David Chassis plate now cut out: Chris. |

|

|

|

Post by Penguin45 on Mar 22, 2014 11:11:16 GMT

Ouch! Glad to hear that you're OK. Will they fix yours?

Chris.

|

|

|

|

Post by Penguin45 on Mar 22, 2014 17:43:33 GMT

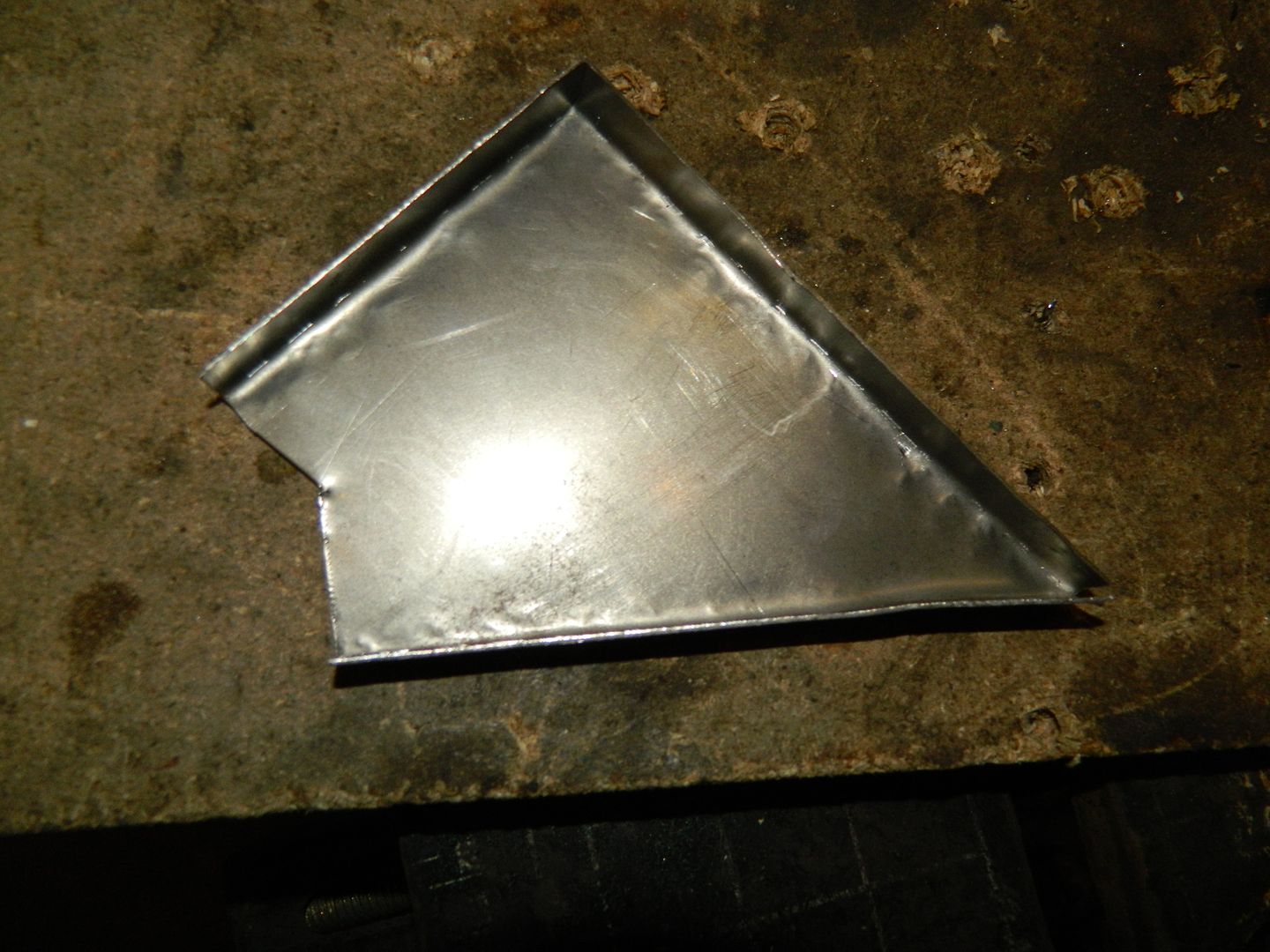

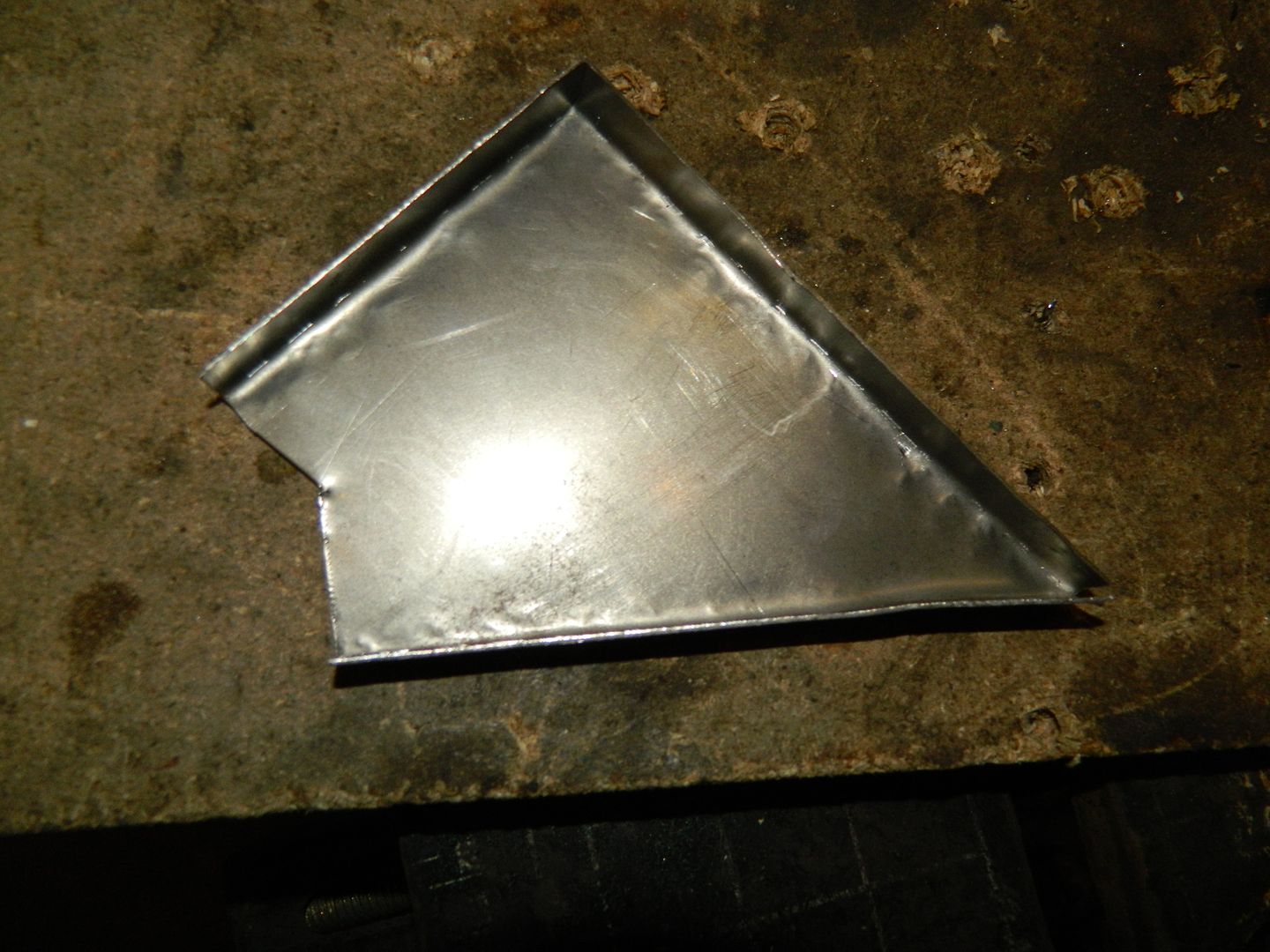

Edges folded over, holes flanged. This is now immensely rigid. Hard work though - I've had enough for today. Chris. |

|

|

|

Post by dave1800 on Mar 23, 2014 1:30:07 GMT

Yes. The insurers work 24/7 and send someone to the crash site to take photos. You can't move any vehicle until after the police and insurers have inspected them which can cause some spectacular jams. The repairers have now taken their photos, inspected the vehicle and ordered the parts. With luck repairs will start the end of next week. I will lose my no claims though as the other party was uninsured but my insurers will take action to try and recover from the other driver who now faces massive bills to restore the very broken Mazda. David Ouch! Glad to hear that you're OK. Will they fix yours? Chris. |

|

|

|

Post by dave1800 on Mar 23, 2014 1:31:24 GMT

Do you think you could make a complete car from scratch  ? Impressed (again). David  Edges folded over, holes flanged. This is now immensely rigid. Hard work though - I've had enough for today. Chris. |

|

|

|

Post by Penguin45 on Mar 24, 2014 0:14:35 GMT

The plate is welded in. As a spectacle, there's not really anything to see. 18 plug welds through the floor, three through the plate into the front inner wing and a seam down the side. Technically, the interesting bit was the difference in the metal thicknesses doing the floor. Floor section is 1mm, chassis plate is 3mm. Turned up power and wire speed to get the heat through the chassis plate quickly - seemed to work. Front end was really "give it power and get some wire in there". Don't think it's going to fall off.

I'll see about some of the lighter metal panels tomorrow and get some pics up.

Chris.

|

|

|

|

Post by bullyboy on Mar 24, 2014 7:22:56 GMT

Edges folded over, holes flanged. This is now immensely rigid. Hard work though - I've had enough for today. Chris. Nice bit of tin bashing, that should last another 40 years PAUL |

|

|

|

Post by Penguin45 on Mar 24, 2014 18:41:34 GMT

Hmmm - what could we make from scratch..........?  Paul, it had better do another 40 years - that was damn hard work!  There it is.  Floor's going to need a serious going over with the angle grinder to tidy up those plug welds. I reverse welded the floor panel from the other side for added strength as well, before the big panel went on.  Made this panel this morning. I suppose it's a TWAIN (Thing Without An Interesting Name), although MrsP decided it was a "gozzin" when she arrived with a cuppa as I was offering it up.  "Why?", I asked, falling headfirst into the trap. "'Cos it gozzin there". She seemed inordinately pleased with that. Anyway, a combination of butt, plug and lap welding saw it home nice and solid. Came to a stop at that point, as the remains of the gigantic bolt which retains the lower engine steady is still stuck very solidly through the suspension housing. Once it's out, I can offer it up and drill the locating hole in the correct place. And finally.......  It's never too late to find new holes.  Chris. |

|

|

|

Post by Nick RS on Mar 24, 2014 22:14:02 GMT

The world of welding is full of double entendres

butt, plug, lap.

The body parts list from BMC also refers to the large chassis plate you made as a 'gusset - side member to dash' ........

......... I'll get my coat.

Nick

|

|

|

|

Post by dave1800 on Mar 25, 2014 3:42:28 GMT

Starting to sound like a "Carry On" film, just need Barbara W to appear in tight fitting clothing with a gusset:) David (Sorry, it's meant to be a joke for sad old UK readers!) The world of welding is full of double entendres butt, plug, lap. The body parts list from BMC also refers to the large chassis plate you made as a 'gusset - side member to dash' ........ ......... I'll get my coat. Nick |

|

|

|

Post by Penguin45 on Mar 26, 2014 18:41:35 GMT

The world of welding is full of double entendres butt, plug, lap. Blame the plumbers - Victorian plumbers started it with "male and female fittings".  Starting to sound like a "Carry On" film, just need Barbara W to appear in tight fitting clothing with a gusset:) Go on then:  Anyway, fairly successful day on the panel front.  Made this chappie.  Had to tweak it slightly, but it's welded home. No access to grind the welds, so bent the flanges to the inside, as they'll finish up boxed in.  View inside out - You can see where I had to tweak the flange under the steering rack. Might revisit that.  Closing piece across the bottom of the inner wing. Quite pleased with that. One bit of fabrication to finish this area off - there is a tube and bracket on the backside of the suspension housing panel. The remains of the engine stabiliser bolt is firmly jammed through the housing, which is now stopping me offering it up to make the bottom hole and thus align the tube and brackets. Tomorrows job perhaps. Chris. |

|

|

|

Post by dave1800 on Mar 27, 2014 1:14:03 GMT

I remember this being an absolute pig on a Mk1 car which was only about 5 years old; it took lots of heat to free it; good luck David One bit of fabrication to finish this area off - there is a tube and bracket on the backside of the suspension housing panel. The remains of the engine stabiliser bolt is firmly jammed through the housing, which is now stopping me offering it up to make the bottom hole and thus align the tube and brackets. Tomorrows job perhaps. Chris. |

|

|

|

Post by indianajones on Mar 27, 2014 8:39:15 GMT

I am in awe mate  -Andrew |

|

|

|

Post by Penguin45 on Mar 28, 2014 17:41:04 GMT

it took lots of heat to free it; good luck Read on - I needed it! I am in awe mate  Aw - shucks.  I did it......  Remains of through-bolt, otherwise known as "Evil Spawn of Satan". Removed bottom arm and rubber bushes, before two hours of bashing, heating, levering, and windy-gunning*.  There you go, it's out. Note tool kit: Blow torch, breaker bar, scaffolding pole, copper faced hammer and windy gun. Managed to induce a small amount of movement with the breaker and scaffolding pole through the bush housing after about 20 minutes of heat. The windy gun then broke it fully free. It's not much to look at, but I'm taking that one as victory. In January, I wouldn't even have contemplated doing this. Mind you, I'm having a breather in the house now as the housing cools down. Being aluminium alloy, it doesn't change colour with heat, so I'm leaving it for an hour. Chris. *If it isn't a word it jolly well ought to be! |

|

|

|

Post by dave1800 on Mar 29, 2014 2:45:03 GMT

I did say it takes a lot of heat  . Aluminium is such a great conductor of heat; did you pour yourself a beer? David I did it...... Remains of through-bolt, otherwise known as "Evil Spawn of Satan". Removed bottom arm and rubber bushes, before two hours of bashing, heating, levering, and windy-gunning*. Chris. |

|

? Impressed (again).

? Impressed (again).