|

|

Post by Penguin45 on Jun 2, 2015 23:40:47 GMT

I see. I've attacked what were deemed to be the affected areas with the angle grinder and wire brush. It's going to take me a while to sweep up.  Front end of drivers sill. This has now been cut to a regular shape and a panel let in flush. Peering through the hole and down the inside of the sill, it doesn't look too bad. Nothing that a gallon of preservative wax won't sort.     These are of the o/s floor at the front. There's a big, solid, very well fitted panel on the inside of the car above this damage. I suspect that the PO didn't quite understand the structure of the car. This'll all have to be cut away and replaced. I should be able to plug weld the new metal to the metal above, which would be very strong. Chris. |

|

|

|

Post by Penguin45 on Jun 6, 2015 23:31:56 GMT

Welding repairs completed. Electric fuel pump conversion has failed - the pump on the shelf has a cracked cover. Something else required pronto. Indicator switch and column shroud sorted. Power steering pump and dynamo stripped off car. "New" pump found to be highly rusted, so lots of cleaning and polishing carried out.

I have pictures which I will post when Photobucket decide that I am the owner of my "Bucket"......

Chris.

|

|

|

|

Post by peppib on Jun 7, 2015 9:40:10 GMT

Ah, the unique feeling after altering pipework, supplying power and turning the ignition on only to see the precious fuel persisting from some unknown pump orifice and onto the garage floor. Another pump arrives, is fitted and then found to be so noisy all the pipework alterations are removed and the original mechanical pump reinstated. After 4 years the electric one still lurks somewhere in the boot, unloved, amongst sundry spares, tools, and other junk I have in there.

Dave

|

|

|

|

Post by Penguin45 on Jun 7, 2015 11:43:02 GMT

Facet pump? Noisy little blighters, even if you hang them on rubbers.

Chris.

|

|

|

|

Post by peppib on Jun 7, 2015 13:55:44 GMT

Facet pump? Noisy little blighters, even if you hang them on rubbers. Chris. Oh yes. It was hung on rubbers but even so the noise was intolerable on a long journey. I did look at one similar to that fitted to my Moggy (no, not the originalSU one) but decided the mechanical one had lasted over 40 years (well, a replacement mechanical one was fitted a couple of years go) so that should see out my time driving. Mind you, she was parked in direct sunshine whilst in pub for lunch today (no alcohol consumed) and took a few moments cranking to get the petrol flowing again Dave |

|

|

|

Post by Penguin45 on Jun 7, 2015 20:04:37 GMT

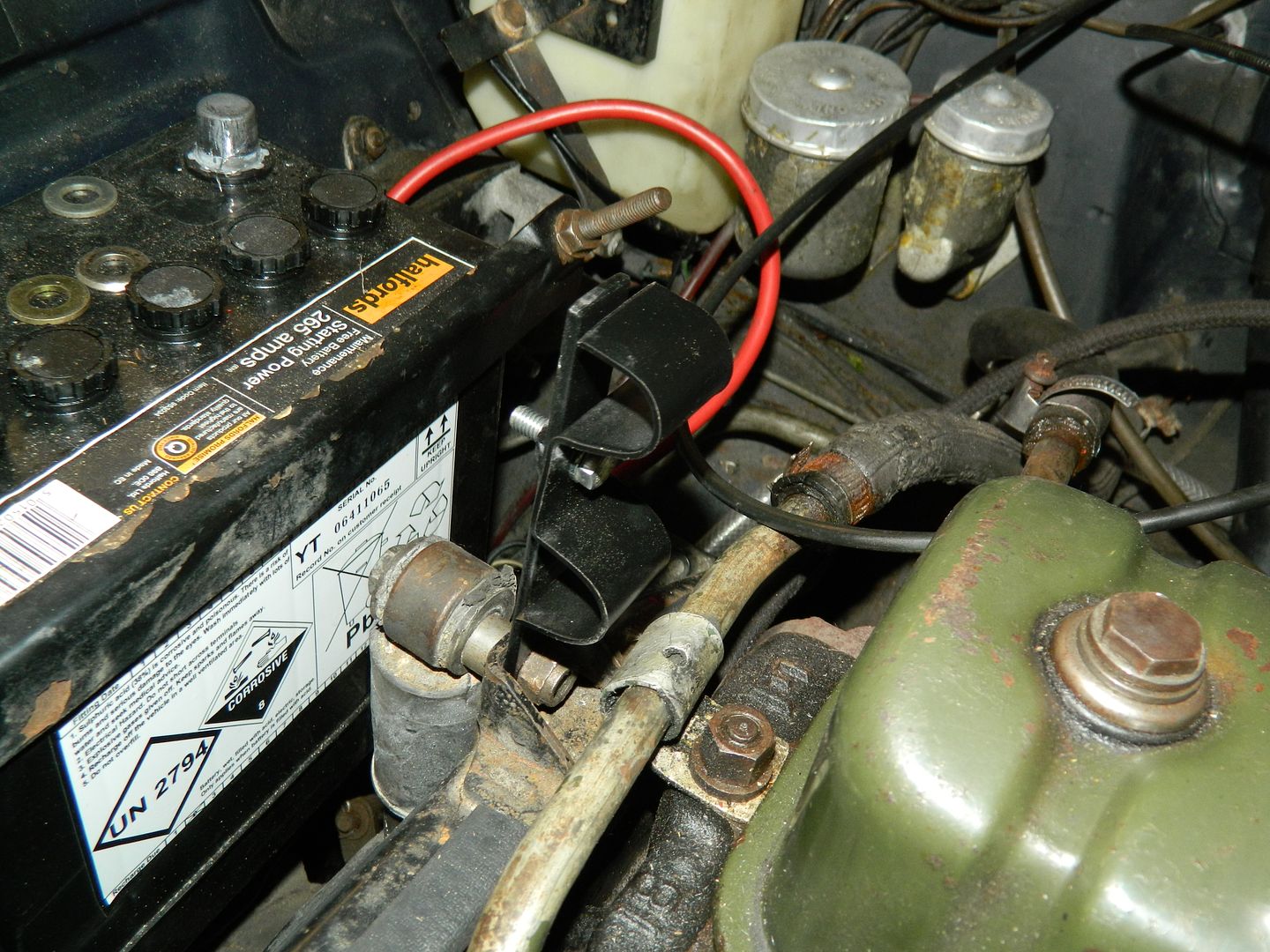

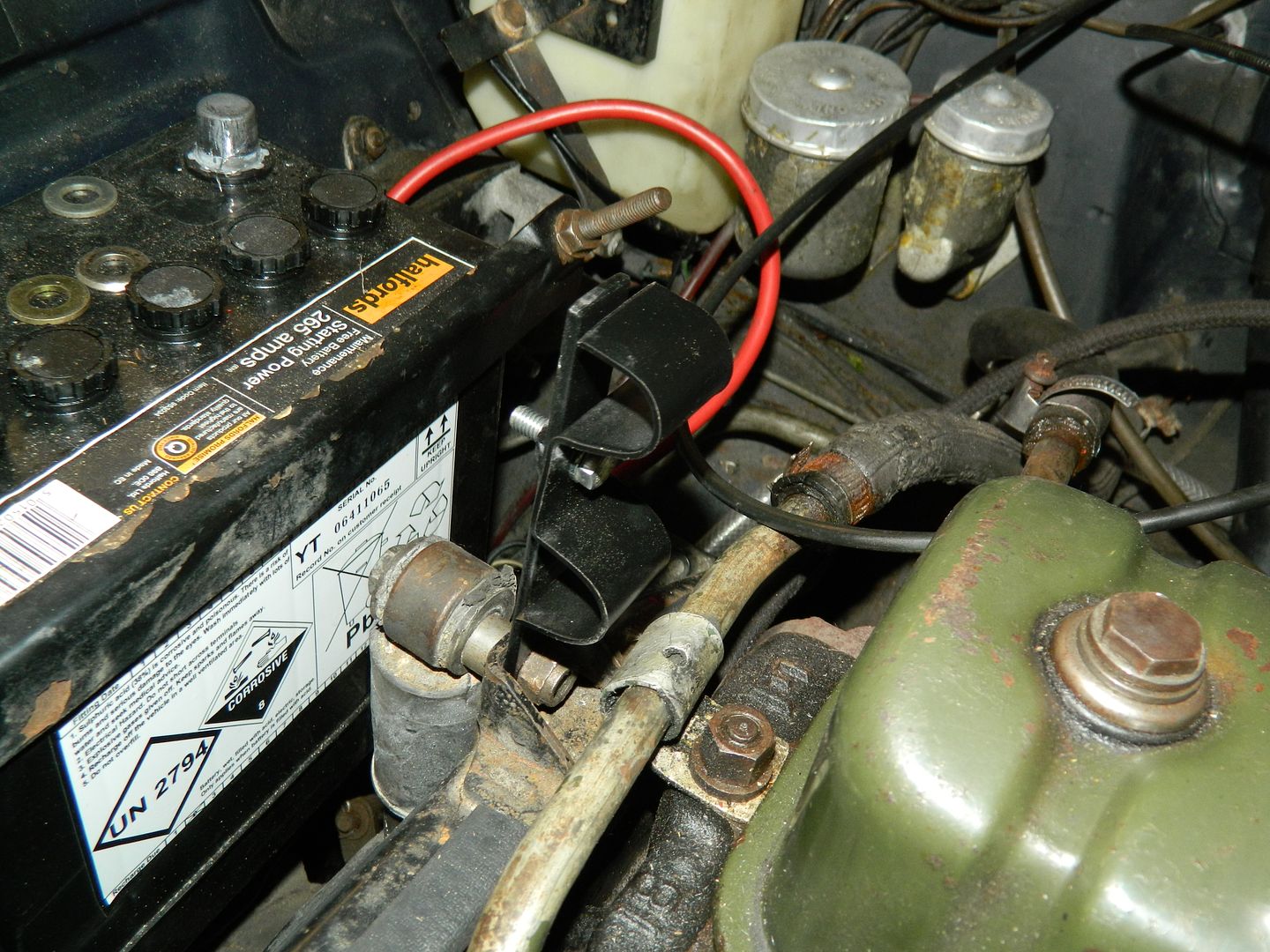

Finally managed to get into one of my Photobucket accounts....  Welding sanded back and treated with etch primer.      Coat of primer, coat of random dark blue paint.   And a thorough coating of underseal should see this area protected for a few years.   Fuel pump:  Mini exhaust bobbins. Wonderful things.   Under the boot floor.  And plumbed up. Power was spurred from a switched live behind the fuse box and fed through the connector blocks before being tied off neatly under the car. It powered up nicely, then tiddled fuel everywhere. The cover is cracked.  A new replacement is on the way.  SU air filter fitted.  Rubber strip fitted to radiator shroud - should cool the engine bay a bit better. Clock refused to run. A closer inspection the words "Positive Earth" at the top of the face. Negative earth car. Hmmm. Took the case off.  Nope - that looks complicated. I know a man who can, so I'll drop it off to be reversed during the week. A considerable amount of time was expended sorting out Snoopy's "new" power steering pump. Seized and lots of rust inside. It's now spotless and free turning. Painted the end casing, bolted it to a replacement dynamo and fitted it back in the car.  Fingers crossed. Snoopy's bringing some new PS hoses over next weekend, so fingers crossed. Last major task is to drain the hydrolastics, flush out the hydraulic fluid and refill with the pukka fluid. Nice little project. Hopefully I'll get my car back (intact!) next weekend and Snoopy can take his away. Chris. |

|

|

|

Post by indianajones on Jun 7, 2015 20:47:33 GMT

Nice update and pics Chris, as always.

Keen to see and follow the procedure of doing the fluid, as that's something I think I should address on my car.

Cheers,

Andrew

|

|

|

|

Post by Penguin45 on Jun 10, 2015 21:09:04 GMT

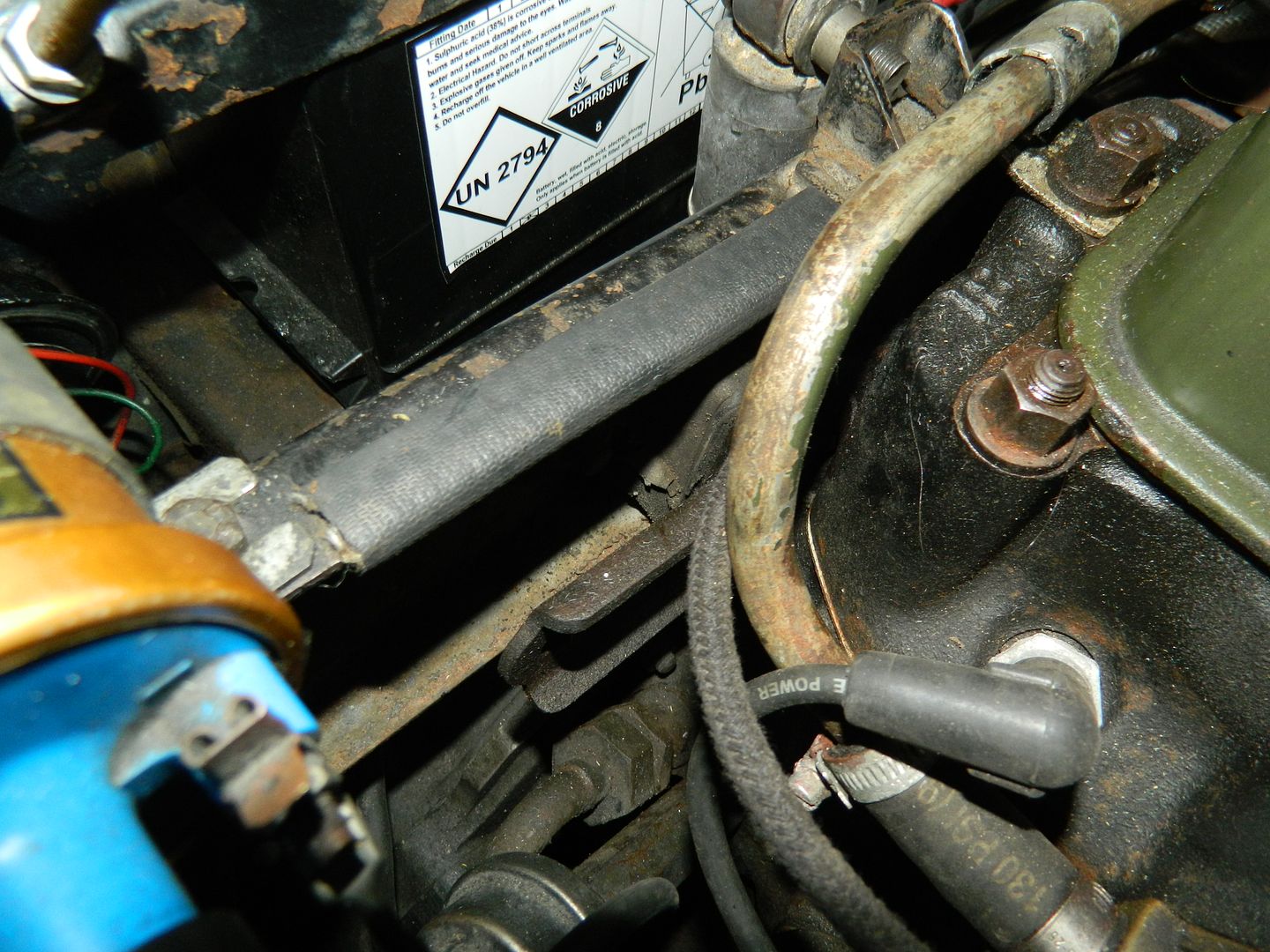

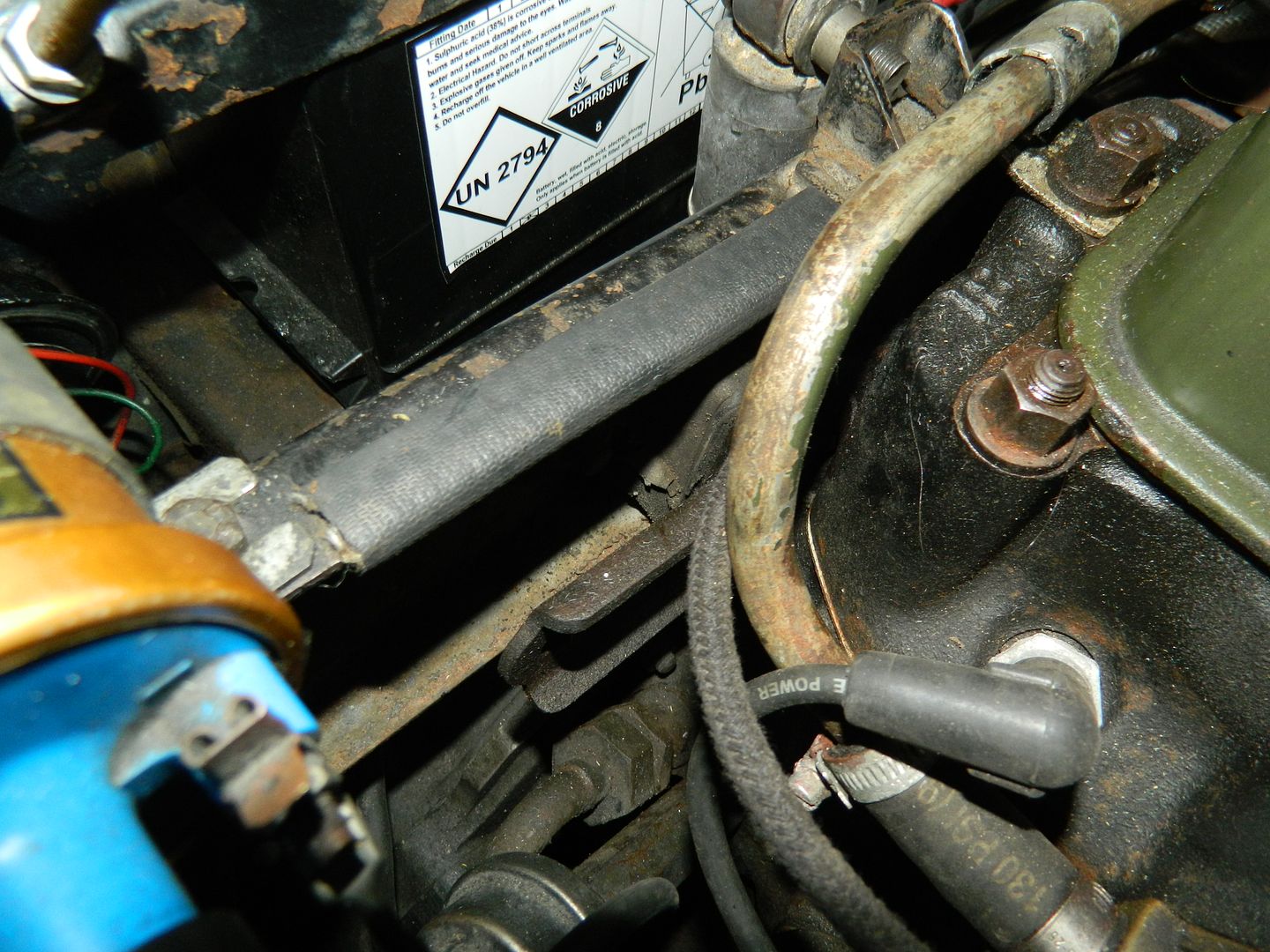

Fuel pump business now sorted.  Pumps well. "Brrred" a bit until it filled with fuel, then couldn't be heard over the engine.  Mechanical pump removed and blanking plate fitted. This should release another 5 IBHP*.   Edge protection added to the engine steady to help prevent the P/S pipes chafing. I have started making the hose clamp to lock the pipes in place, but somebody needs to tell me the diameter of the new pipes pretty soon or it won't be done for Saturday.  Tappet chest cover fitted with silicone rubber gasket. Coated both surfaces with Loctite 5922 on the belt and braces and safety pins principal. Might not leak... For a while, anyway.  Oddly enough, the other one, with the breather on it, is bone dry, so I've left it alone. Chris. *Imaginary Brake Horse Power. Usually added in the form of dropped suspension, dodgy body kits, enormous bass bins and the like.  |

|

|

|

Post by Penguin45 on Jun 12, 2015 14:27:42 GMT

Last bit done ready for tomorrow:  Clamp for P/S hoses. Never actually seen one on a car, so this is mugged up from the illustration in the Workshop Manual. Should work  Chris. |

|

|

|

Post by Penguin45 on Jun 13, 2015 21:12:30 GMT

What a day. There were two principal objectives to today's activities. Plumb-up the power steering and flush out and refill the suspension. Due to the restrictions of space, we decided to do the suspension first, as the access was better without the P/S hoses in place. The system had been filled with hydraulic fluid rather than hydrolastic fluid, so we drained the o/s down using the valves on the über pump to control the flow and to stop air entering the system. We then filled and drained the system with plain water three times, observing that what came out each time was increasingly less oily. Some small amount of time was spent pondering the vagaries of the system when inflating. The o/s would rise to about 360mm, then go "Boing!" and surge up to 400mm! We bled some fluid out to bring things back to the correct height. Bouncing the car vigorously then showed it too low..... This is still with water, not hydro fluid. We repeated the process on the n/s. With the third flush out, the rear displacer exploded. Snoopy was doing the pumping at the time, so it's obviously his fault.  So, with the car now canted over at an interesting angle, we set about plumbing up the power steering. We spent a lot of time getting the hoses routed the most natural way to avoid fouling and chafing on the body work and each other. The designer hose steady worked a treat. The system was then filled, the battery re-connected and the car started. There was the mosy godawful racket...... None the less, we bled it thoroughly and it quietened down. A bit. If I'd been slightly quicker off the mark, I could have entertained you with some footage of a lopsided 'Crab going for a quick run up the road. Upshot is that the "new" pump is just as noisy as the old pump. Rats. Right. The car isn't going back to Bolton today, so we might as well get the rear displacer out. From lifting the car to pulling out the displacer - 12 minutes. I love my windy gun.  Found a new hole to be welded.  Decisions had to be made about the steering. I have an unused, reconditioned manual rack on the shelf, so we're going to put that on. Started by stripping out the pump, dynamo, new pipework and got covered in ATF as a consquence. We're currently having a complete 'mare trying to extract the powered steering rack. We might have to get the ram off it before it'll come through the inner wing. Have a few pics:   When I said "exploded", I meant exploded! I doubt Tony will want that as an exchange.   Good messy fun. Not.  Snoopy's turn to go paddling in the ATF. We're going to try and get the steering sorted tomorrow. Hopefully Tony will send a displacer out during the week. Beer o'clock - see you all later. Chris. |

|

|

|

Post by dave1800 on Jun 14, 2015 1:50:44 GMT

Definitely the fault of the person doing the pumping  Difficult to see from the photo but had the hydraulic fluid damaged the displacer rubber? I don't see why it should but just curious. How about converting to non PAS/ It's much nicer in my opiniion. David What a day. The system had been filled with hydraulic fluid rather than hydrolastic fluid,...... With the third flush out, the rear displacer exploded. Snoopy was doing the pumping at the time, so it's obviously his fault.  Chris. |

|

|

|

Post by snoopy11 on Jun 14, 2015 17:19:33 GMT

I just want to really thank Chris for all his help with the car over the last couple of weeks. A lot of this just would not have happened at the moment due to trying to juggle work and family commitments and having a close relative seriously I'll in hospital. The car would probably not have been sorted this summer. Again. Thanks Chris. You have been a bit of a hero. |

|

|

|

Post by Penguin45 on Jun 14, 2015 20:31:32 GMT

Cheers Mark. We'll get there.

David, yes, we'll swap over to manual steering.

I got the power rack out in the end and the manual one is partially attached. Have had to order up some new bolts, so we're stopped again now. I can be getting on with the odd bits of welding during the week, so stuff to be doing.

Chris.

|

|

|

|

Post by dave1800 on Jun 16, 2015 2:51:24 GMT

You know the bits you need to change, reference the exercise on the suspension warning? Let me know if you want originals of the spreadsheets. D David, yes, we'll swap over to manual steering. I got the power rack out in the end and the manual one is partially attached. Have had to order up some new bolts, so we're stopped again now. I can be getting on with the odd bits of welding during the week, so stuff to be doing. Chris. |

|

|

|

Post by Penguin45 on Jun 16, 2015 16:16:52 GMT

Not sure how far we can go with that at the moment, David. It also depends on Mark's longer term plans - whether or not to get the P/S pump sorted professionally and re-instate the whole system, or to try it on manual and see if he likes it and develop it properly from there.

Displacer arrived today, so rear suspension is now back in the car. Took me 25 minutes, but I was working single-handed this time. New brake line made and fitted as the one fitted was passing between the handbrake spring and the actuating rod on the back plate. Not a good plan. That's all bled off, so just blowing it up now. An unfortunate choice of phrase seeing as it literally blew up last time!

Right - go and do some more.

Chris.

|

|

A new replacement is on the way.

A new replacement is on the way.

Found a new hole to be welded.

Found a new hole to be welded.