|

|

Post by Penguin45 on Aug 30, 2013 20:52:40 GMT

It's done. Level, fuel tight, washer system re-primed...... Just a good clean and perhaps a bit of a polish for Sunday to go.

Tommy, it never occurred to me to push the displacer home with the suspension housing - I had shoved it all the way down the tube and was trying to engage the ball virtually blind behind the housing. I've made a note of that in case there is a next time.

Otherwise, thanks for the support. Always nice to know there is help and advice available.

Chris.

|

|

|

|

Post by dave1800 on Aug 31, 2013 2:21:30 GMT

Alexander, Chris, Tommy (in alphabetical order  Very interesting. I have been looking at the construction of the hydrolastic units and the only suspect thing I can see is the rubber damper valve if this were somehow possible to become (temporarily) trapped to act as a one way valve to satisfy Alexander's pumping up observations or in Tommy's case it may not fully open creating too firm damping. Pure speculation by me of course. Chris, you did not say whether pumping up the suspension on the side with the new unit settled the other side or whether you left it as it was or released some of the pressure? I do recall reading somewhere that they hydrolastic units with firm medium and softer settings. Whether this is true I have no idea but maybe they matched units to take into account manufacturing tolerances? David I guess the moral of the story is to block the front suspension arm from moving down when changing the engine. However the blue one seems to have this condition almost permanently, on the left side. When this occures, it appears to me the front damping on the affected side is very stiff, while the rear is very soggy. Could the displacer stick in some way? I mean, there is a valve in there? Perhaps this is what happened to yours too? It falls down on one side, as a result of this it raises on the opposite side and the displacer(s) on this side stick(s) in raised position, also when you pump the other side up. Just a thought... We once had a displacer fitted to the LH front of my father's crab, that seemed to have a one-way valve installed: During driving it would receive some fluid when the rear wheel went over bumps, but the fluid would not go back - so jacking up the corner of the car. We did not find the fault in the unit (it was one received from Tony Wood with a new hose clamped onto it and had this fault immediatly after installation). It acted a bit like it happens occasionally with brake hoses that are locking up inside. While the garage men scratched their head how to extract the unit that would not let the fluid go, the blockage went and it could be taken out as if nothing has happened.... Sure enough, coil springs are pretty boring in comparison! Regards, Alexander |

|

|

|

Post by Penguin45 on Aug 31, 2013 8:17:03 GMT

We had to bleed off some fluid on the off-side - went a trifle low and pumped it back up again.

Chris.

|

|

|

|

Post by dave1800 on Aug 31, 2013 11:52:49 GMT

Found it on Austin America (1100/1300) website: link"In essence, until about 1972-73 all ADO16 displacers are the same, colour coded green. Front and rear ones (apart from the obvious valve difference) had a different knuckle joint connecting rod, short at the front, long at the back, but these are interchangeable. The blue coded ones were having only a slightly longer rod, to compensate for the heavier transmission of the automatic cars. The last cars had displacers with stiffer internal valves and were coded orange." Now as the front 1100/1300 displacer is I believe the same as the 1800 rear perhaps there are some odd mixes around. How about the 1800 knuckle joint con rods weren't there some changes between Mk1 and Mk11/111? David Alexander, Chris, Tommy (in alphabetical order  I do recall reading somewhere that they hydrolastic units with firm medium and softer settings. Whether this is true I have no idea but maybe they matched units to take into account manufacturing tolerances? David |

|

|

|

Post by Penguin45 on Sept 1, 2013 23:36:51 GMT

Did the Hutton-Le-Hole do on Sunday; a most pleasant day out - see Picture Forum for the pictures. She ran very nicely (and - finally - quietly!) the 60 some miles each way. Bit of a joy, really.

A whine from the front turned into a Brrrrr on the way up, and a Grrrrr on the way back. Front near side wheel bearing, I think. No immediate panic as there are no more runs out planned immediately and there is little obvious play on the wheel. On the list......

Chris.

|

|

|

|

Post by dave1800 on Sept 2, 2013 1:06:09 GMT

Great pics! Now replacing the front wheel bearing would make a great video. You can liaise with Kels. I know he just loves that job  . I found it a bit daunting first time, but is something most owners will probably face some time. regards David Did the Hutton-Le-Hole do on Sunday; a most pleasant day out - see Picture Forum for the pictures. She ran very nicely (and - finally - quietly!) the 60 some miles each way. Bit of a joy, really. A whine from the front turned into a Brrrrr on the way up, and a Grrrrr on the way back. Front near side wheel bearing, I think. No immediate panic as there are no more runs out planned immediately and there is little obvious play on the wheel. On the list...... Chris. |

|

|

|

Post by Penguin45 on Sept 2, 2013 18:07:51 GMT

Now replacing the front wheel bearing would make a great video. Should have seen that one coming..... I will definitely liaise with the movie camera man (Alex), producer (Alex) and director (Alex). I'll possibly need an editor (Alex) and title maker (Alex) as well. Looking at that lot, I might have to pay him. I found it a bit daunting first time, but is something most owners will probably face some time. hammer.  Hugely satisfying. Chris. |

|

|

|

Post by Penguin45 on Oct 6, 2013 15:41:48 GMT

Not done anything to the car for a while. Did the engine steady this afternoon - SEE TECHNICAL FORUM and then had some fun with cavity wax.  Lovely messy stuff. I really wanted to fill the void space behind the wheel arch repair that I did last time, and did both sides. There were a couple of very long flexible lances in with the cans - perfect for poking right inside these blind spaces. Otherwise, I've not done much at all. College and work together are taking a bit of a toll. College is immensely enjoyable though. Chris. |

|

|

|

Post by Penguin45 on Oct 12, 2013 0:22:17 GMT

Wheel bearing - must do wheel bearing.......... Sunday perhaps.

Chris.

|

|

|

|

Post by Penguin45 on Dec 2, 2013 0:04:55 GMT

Hmm - time has passed. Wheel bearing not done, but then she hasn't really been out for two months. Today, she stubbornly refused to start at all. My fault, she's jealous of the new resident in the garage.

Fuel, yes. Sparks, yes. Run? No...... If cranked for a while, little pops in the exhaust and at one point a most satisfying backfire. It's almost as if the timing has slipped way out. Should be impossible. One more thing to investigate. Time - need more time.

Chris.

|

|

|

|

Post by dave1800 on Dec 2, 2013 1:10:24 GMT

Perhaps the fuel has gone off? David Hmm - time has passed. Wheel bearing not done, but then she hasn't really been out for two months. Today, she stubbornly refused to start at all. My fault, she's jealous of the new resident in the garage. Fuel, yes. Sparks, yes. Run? No...... If cranked for a while, little pops in the exhaust and at one point a most satisfying backfire. It's almost as if the timing has slipped way out. Should be impossible. One more thing to investigate. Time - need more time. Chris. |

|

|

|

Post by Penguin45 on Mar 1, 2014 18:57:44 GMT

She's off again. Tut, tut, laid up for four months......

No doubt this will definitely amuse David - I got her going aqain by converting her back to points and standard coil. Stop laughing at the back - I can see you. Brand new high quality points, condenser and red rotor arm into a 45D 41415 distributor and a standard coil. Set gap to 15thou". Set timing to 12°BTDC and she was off second turn of the key. I'll drive down to college on Monday and see how she behaves.

Chris.

|

|

|

|

Post by snoopy11 on Mar 1, 2014 23:21:14 GMT

That's what you get for laughing at me and my sticky clutch the other week.

Glad your going again.

|

|

|

|

Post by dave1800 on Mar 2, 2014 1:22:44 GMT

Now what was it you do to feed the family? Oh yes repair electronic home appliances. How about getting rid of those pesky bits and fitting clockwork timers? Actually maybe not a bad idea  Great to hear the car's up and running again. Perhaps as a sop to the modern world you could consider setting the points with a dwell meter, much easier and more accurate than setting the gap imho. I'm still laughing! regards David She's off again. Tut, tut, laid up for four months...... No doubt this will definitely amuse David - I got her going aqain by converting her back to points and standard coil. Stop laughing at the back - I can see you. Brand new high quality points, condenser and red rotor arm into a 45D 41415 distributor and a standard coil. Set gap to 15 thou". Set timing to 12°BTDC and she was off second turn of the key. I'll drive down to college on Monday and see how she behaves. Chris. |

|

|

|

Post by Penguin45 on Mar 2, 2014 15:35:15 GMT

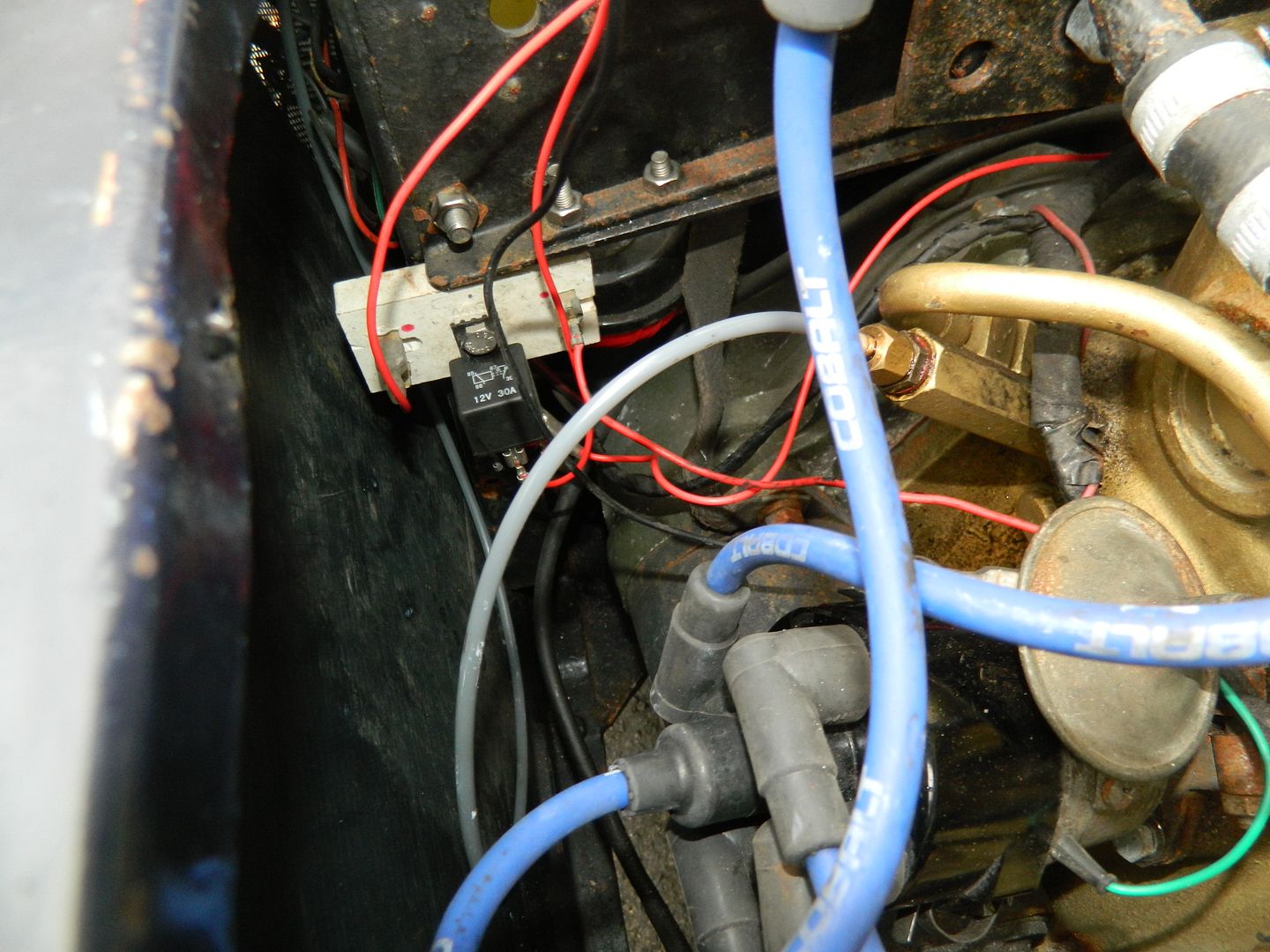

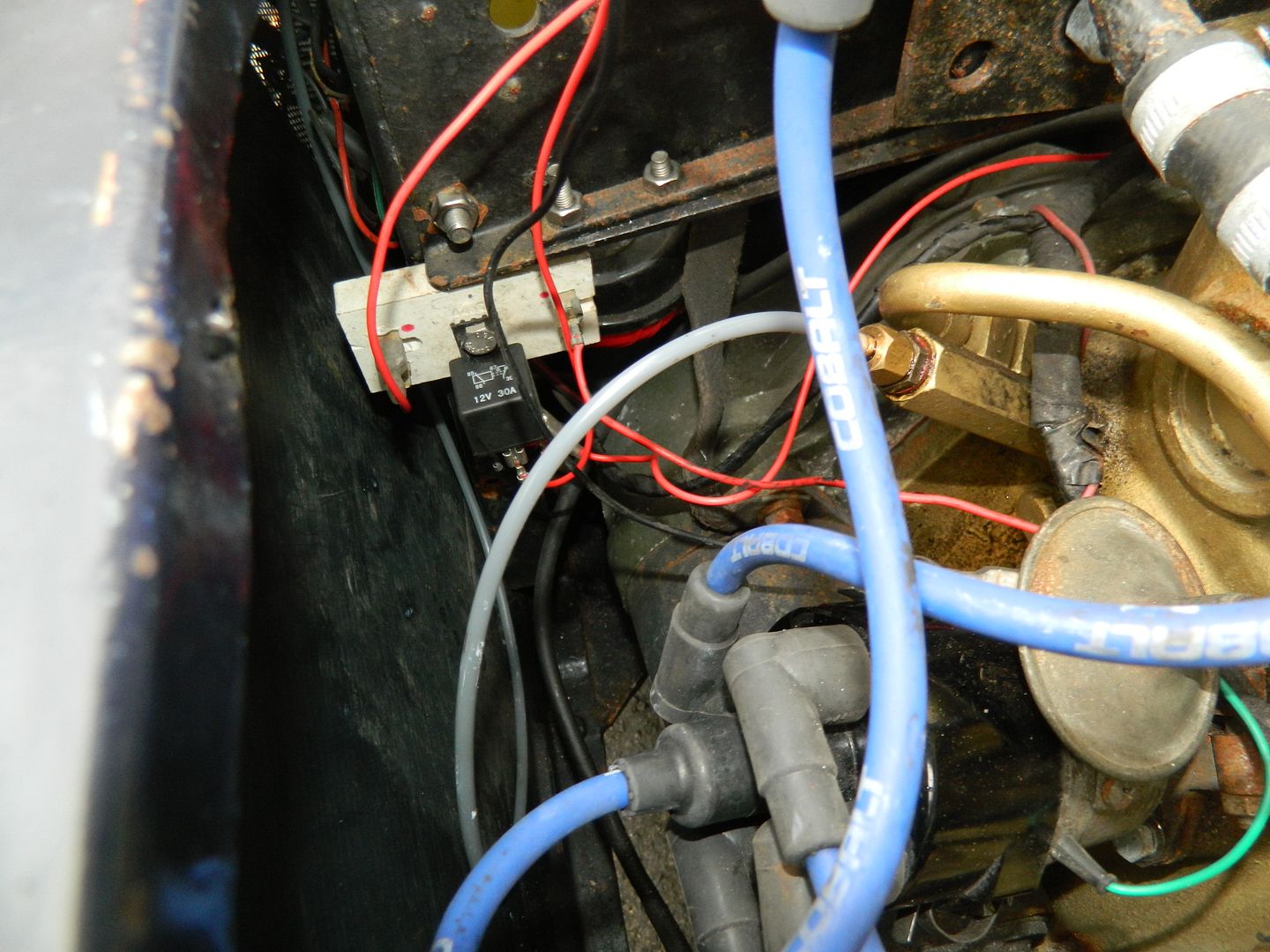

All right, I see, I see.............  Explain these then:   Being mindful that none of my electrical fixes ever seem to be quite standard, of course. Chris. |

|

.

.