|

|

Post by Penguin45 on Oct 25, 2012 0:33:47 GMT

Cheers, chaps. It was definitely an educational afternoon and the main thing that sticks in my mind is that it's almost impossible to do single handed. Anyway. The run back now allowed me to hear the erratic "clonk" much more clearly. Sunday afternoon, I popped her up on the axle stands, chocked the suspension and worked out that the the offside lower balljoint is shot; having at least 3mm of play in it. Removed it by splitting the joint and zapping it with the windy gun. Not quite straightforward, as I don't have a deep 1+ 3/4" socket, so had to chop the pin off with the angle grinder before the socket would fit. Having successfully destroyed and removed the joint, I found that I didn't have a replacement; having used the last one for the MoT advisory. My stock management is evidently rubbish. Monday evening saw an extensive rummage on eBay and the very reasonable purchase of some ball joints, a 45mm deep impact socket and a seal kit for my supposed brand new Lockheed servo, which has chosen to start weeping fluid at this time. Got home this evening and they were all waiting for me. There are times when I love ebay. That said, there are times when it is a complet pain in the behind. Indy and I have made a joint purchase of some new OS indicator lenses and the the seller is being a complete tw@t. Two months have gone by, lots of talk and no lenses. I suspect that the bargain price we got them for has upset him. I do have slightly bulldog tendencies, so now that I've got hold, I ain't letting go..........  P45. |

|

|

|

Post by dave1800 on Oct 25, 2012 3:32:32 GMT

I thought your car's last MOT wasn't many miles ago? Any idea why the rapid wear? Regards David the offside lower balljoint is shot; having at least 3mm of play in it. ....having used the last one for the MoT advisory. P45. |

|

|

|

Post by indianajones on Oct 25, 2012 6:32:00 GMT

Indy and I have made a joint purchase of some new OS indicator lenses and the the seller is being a complete tw@t. Two months have gone by, lots of talk and no lenses. I suspect that the bargain price we got them for has upset him. I do have slightly bulldog tendencies, so now that I've got hold, I ain't letting go..........  P45. lol it's been a while hasn't it? I reckon I get them by the time my first child is born! -Andrew |

|

|

|

Post by Penguin45 on Oct 25, 2012 20:05:03 GMT

I thought your car's last MOT wasn't many miles ago? Any idea why the rapid wear? Regards David Curious, isn't it? Did the nearside lower for the MoT advisory and done perhaps 2.5k miles this summer. Anyway, I love my windy gun. Zap on new ball joint, measure gap at flange, zap it off, add tab washer and shims, zap it on, job done; 10 minutes. Having a deep 45mm impact socket is the answer. Indy - I will win......... Chris. |

|

|

|

Post by Penguin45 on Oct 28, 2012 19:29:38 GMT

This weekend I have rebuilt the servo (leak, sticking front calliper), bled the brakes and levelled up the suspension (nearside kipping a bit).

Got a charity stunt for the Wolseley Owners Club to do on Wednesday in Golcar. Golcar isn't exactly flat, so thought she'd better be in the best of fettle.

Chris.

|

|

|

|

Post by Penguin45 on Mar 3, 2013 15:59:53 GMT

Ooh - not put anything in here for a while. MrsP has been driving down to Horsforth and back in Eugenie every morning since the New Year. She has driven the car further this year than I have! This winter driving is not good....... Today I've given the car a very thorough wash and towel down - she looks much happier now. Skipped out the assorted rubbish which has been accumulating due to the kids being run around in it. Dropped in the rather more "period" floor mats for the front. Dismantled and repaired the door mechanisms for the nearside doors. Studied the damage to the paintwork across the front of car. Decided to pretend it's not there.  Easter perhaps. Have had to do some work on the new van - heater fan burnt out the wiring again. Ripped it all out and remade the wiring with uber-heavy-duty stuff and a 16 amp switch. Finally sorted out the lack of screen washer. Removing front wheel and arch liner allowed access to the washer bottle and motor. This showed that the unused front fog-light connector was connected to the washer motor. Replacing it with the other dangling connector restored function. Oh, I nicked a couple of wheels from the old van, as they were brand new just before it conked. And we won't mention the Matiz. B@gger - just did. Chris. |

|

|

|

Post by Penguin45 on Mar 10, 2013 19:52:23 GMT

Another failure to get the ignition working........  Dealt with the "clonk" MrsP had reported during the week. N/s tie bar bushes had failed.  Windy gun to drop the housing down, then strip out old bushes.  They'll be completely knackered then!  Old and new - bit of a difference.  I was concerned to see the wear on the shaft, compared with the new one. However, the new rod is significantly longer, so is not a direct replacement. Offering everything up suggests that the rod is not running straight through the housing. Winding up the new nylock nut compressed everything really tightly, so I've left it as is. I took the opportunity to de-rust and paint the inside of the housing, as well as the gusset panel above, then bolted it all back together. No clonk. I should of course do the other side as well, but Brain of Britain here has mislaid the rubbers for the other side. I had them out to photograph for Indy............ Chris. |

|

|

|

Post by indianajones on Mar 11, 2013 0:12:16 GMT

My bad! sorry mate!

-Andrew

|

|

|

|

Post by dave1800 on Mar 11, 2013 2:24:37 GMT

Definitely Andrew's fault! Have you checked (a) the camera bag (b) outside when you went for a smoke (c) the fridge when you went to get a beer or (d) the other side tie rod which you may have done in a bored trance  Have you ever discovered why there is a thick polythene gasket between the tied-rod carrier and the gusset plate - alignment bodge maybe? Maybe that has disintegrated over the years? regards David Old and new - bit of a difference.  I was concerned to see the wear on the shaft, compared with the new one. However, the new rod is significantly longer, so is not a direct replacement. Offering everything up suggests that the rod is not running straight through the housing. Winding up the new nylock nut compressed everything really tightly, so I've left it as is. I should of course do the other side as well, but Brain of Britain here has mislaid the rubbers for the other side. I had them out to photograph for Indy............ Chris.[/quote] |

|

|

|

Post by Penguin45 on Mar 17, 2013 16:53:53 GMT

I gave in and ordered a pair of bushes from Tony Wood. Immediately after I fit them I will (Of course!) find the missing pair......... Complete disaster this afternoon. Whilst out for a potter this afternoon with my lovely new ignition system, the green flasher on the end of the stalk stopped working. ;D ;D ;D Back in the garage, I dropped the steering column cowls and removed the switch.  Red wire broken. Dob of solder, red and white wires into that little clip and function was restored. Whew...... Refitted the weather shield across the grill. By pure fluke, this has a one inch gap at the top, thus encouraging airflow across the ignition module. I thought that this was supposed to get quite hot - after an hours running, it was stone cold. Presumably the heat sink is doing its job. Front carpet has worked loose, so that's now secured. Chris. |

|

|

|

Post by dave1800 on Mar 18, 2013 0:56:39 GMT

They do get very hot without an effective heat sink as I found out on my Saab 900 (different unit but similar) when the mounting bolts worked loose and it overheated causing misfiring. I actually burned my fingers on the unit. I see you have fitted an aluminium heatsink whch is a far better thermal conductor than steel. regards David Refitted the weather shield across the grill. By pure fluke, this has a one inch gap at the top, thus encouraging airflow across the ignition module. I thought that this was supposed to get quite hot - after an hours running, it was stone cold. Presumably the heat sink is doing its job. Chris. |

|

|

|

Post by Penguin45 on Apr 6, 2013 23:23:44 GMT

Working on the n/s wing at the moment. It's taken all week, but we now do appear to have primer sticking to the metal around the sidelight pod area. Rest of the wing has been rubbed back and primed, so one final flatting tomorrow and we might get some top coat shot on. Weather forecast is hopeful........

Chris.

|

|

|

|

Post by Penguin45 on Apr 7, 2013 21:04:04 GMT

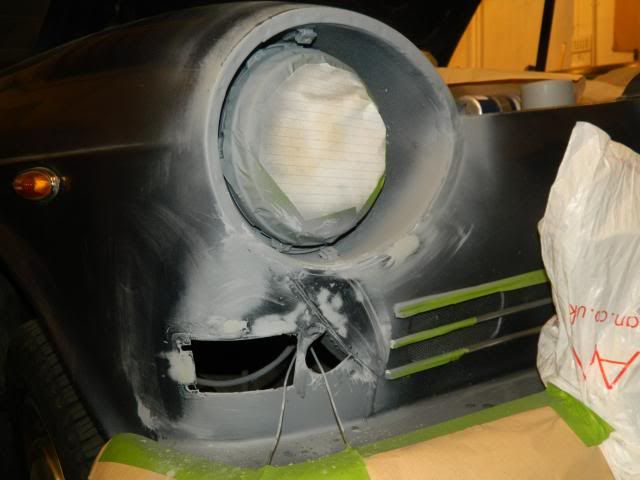

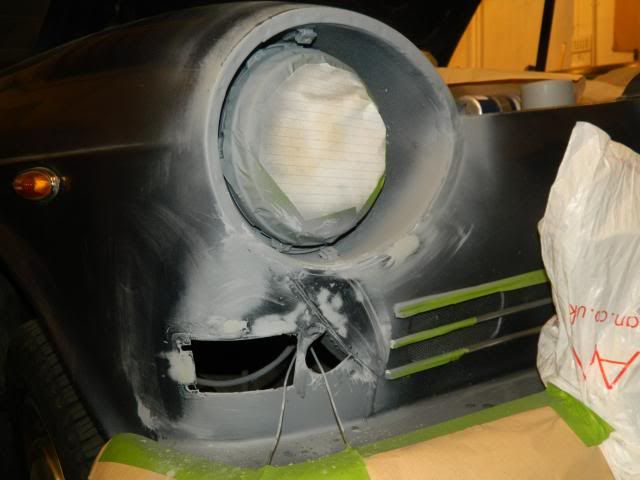

Here we go:  Primer flatted back. There is etch primer and high build primer under there, so it should hold up this time.  Guide coat - more flatting followed.  First two coats of colour. Lots of orange peel, so copious flatting back with 600 grit.  Getting started on the off side. Going to try and keep this as a localised repair - the rest of the wing's not too bad. I've left plenty of time between coats and treatments, and everything has been scrupulously cleaned, so hopefully this time the paint will stay on the car. More soon. Chris. |

|

|

|

Post by dave1800 on Apr 8, 2013 8:47:57 GMT

The weather must have improved at last! Just one query your guide coat looks to be a different colour to the top coat - is this intentional or just a trick of the light? I found this website that others may find useful that provides what I think is a good summary of how to achieve a good paint finish by getting the priming right. hereRegards David Working on the n/s wing at the moment. It's taken all week, but we now do appear to have primer sticking to the metal around the sidelight pod area. Rest of the wing has been rubbed back and primed, so one final flatting tomorrow and we might get some top coat shot on. Weather forecast is hopeful........ Chris. |

|

|

|

Post by Nick RS on Apr 8, 2013 20:38:42 GMT

Chris, I'm sure all your of hard work and patience will pay off with a great looking car. I found some crusty bits in my offside rear arch this weekend, probably shouldn't put it off too long.

Nick

|

|

Easter perhaps.

Easter perhaps.