|

|

Post by dave1800 on May 26, 2017 11:41:49 GMT

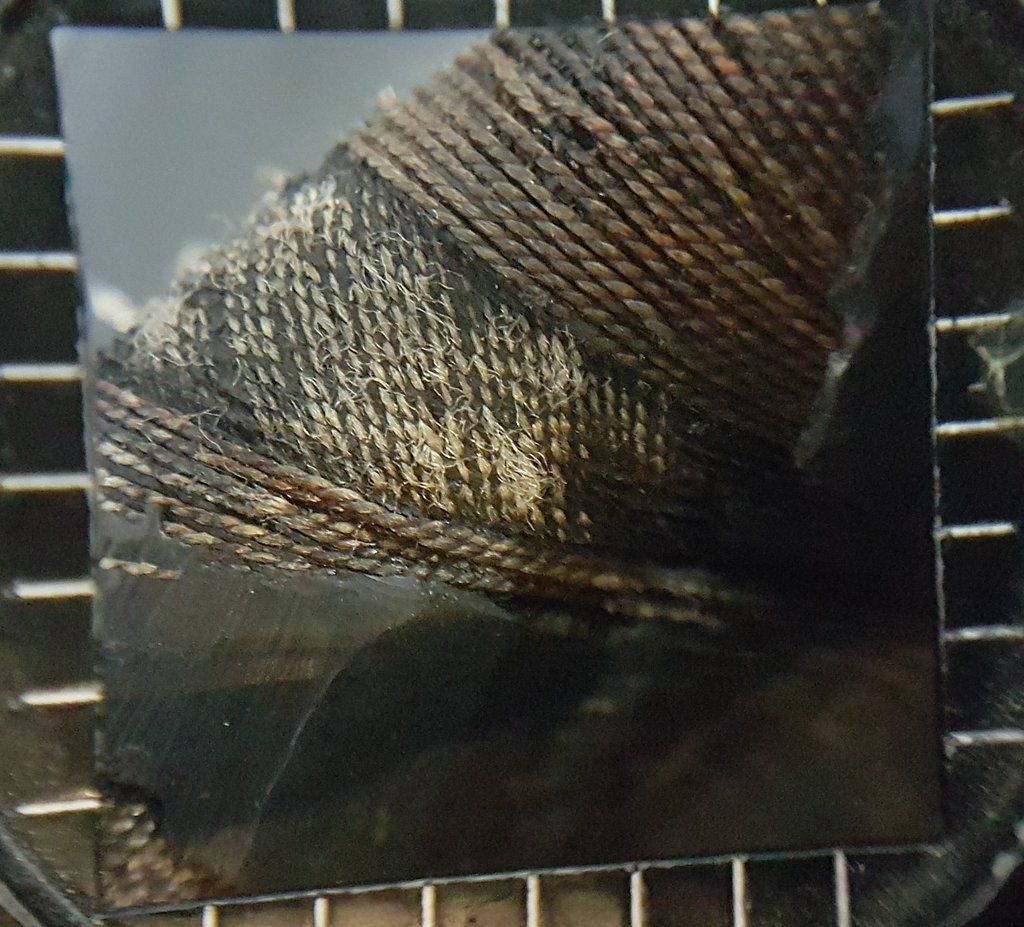

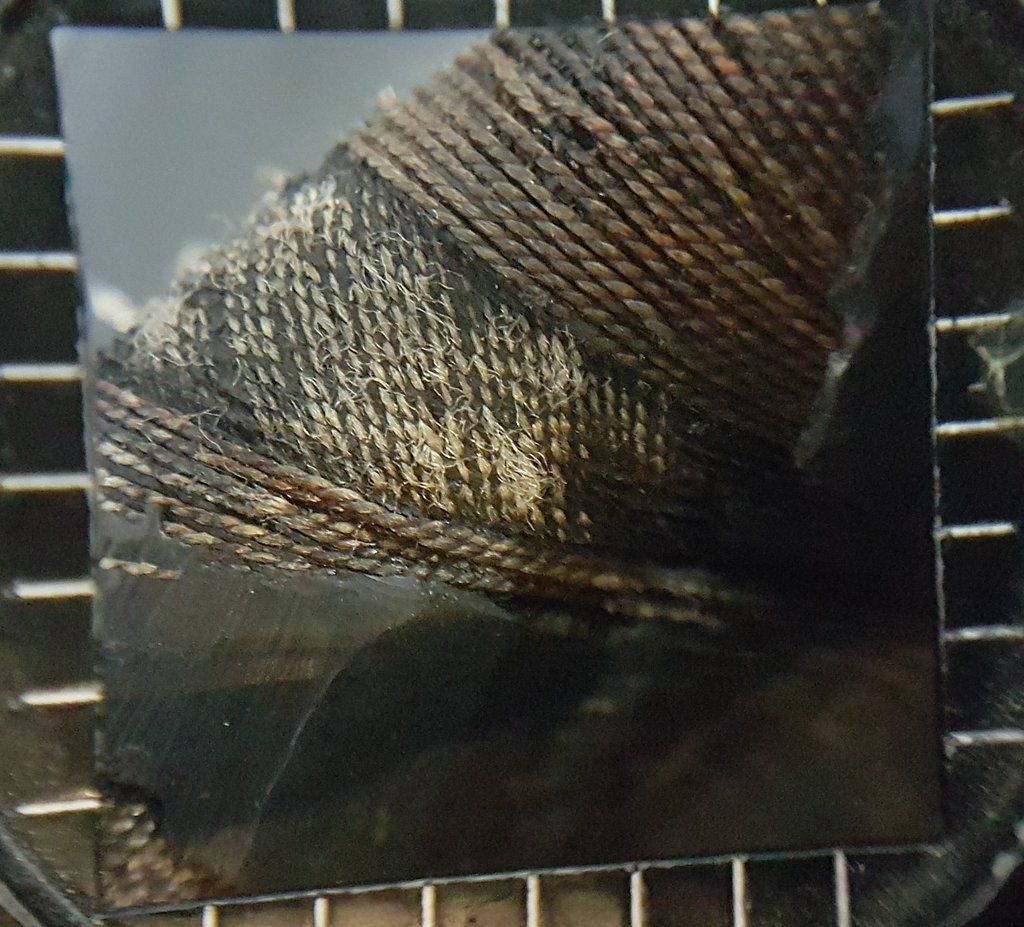

Nick (1800heap) has been working hard dismantling failed displacers as part of the project to remanufacture the units. Attached are a selection of high quality photos showing the various components and the type of corrosion he has encountered. He used electrolysis to clean them up as far as possible they looked far worse when opened! You will see that despite the metal components being cadmium plated the years have taken their toll. There was never any official advice offered, as far as I am aware, covering the service interval for changing the fluid, however it is likely that the anti-corrosion compounds do get used up. Failure to evacuate the system when replenishing may well add to the problem by not minimising the amount of oxygen. If anyone has experience of a NOS unit suffering premature failure please could you let us know if the unit was "scragged" as per the BMC /BL manuals.

It would be helpful if you do not discard any failed units at this time if you are able to store them as there could be a range of options for their renovation or remanufacture.

Many thanks again to Nick for his excellent contribution.

David The weave of the nylon  The dreaded rust  Not looking healthy  Diaphragm   A neat job  Looking up the hose    Rear unit cast  All the bits  Close up of the nylon weave  Nylon fibre  Cleaning  |

|

|

|

Post by steve4487 on May 26, 2017 20:11:51 GMT

Hello Dave

I served my apprenticeship at a BL dealer from 1971 to 1975 and I worked on Landcrabs on a very regular basis. As far as I can remember there was never a change period for the hydrolastic fluid.

When a Landcrab came in for a suspension retrim which a mechanic was allowed 1.5 hours per side the correct method was to depressurize each side in turn, evacuate and re-pressurize, checking for leak, which involved pumping up to maximum height and "scragging", which was basically shaking the fu*ck out it, letting the car settle and then re-trimming to the correct height.

When a Landcrab came in for a retrim they only ever got pumped up, and let back down to the normal trim height, run up the road and checked again. When mechanics were on bonus these jobs were good earners.

With regard to re-manufacturing hydrolastic displacers a way round this issue would have to be found as without this type of suspension system the cars would be worthless, as to use a modern expression the hydrolastic suspension system is a Landcrabs unique selling point.

Trying to adapt another suspension system would entail all sorts of issues with regard to insurance and claims should any such systems fail. This would also apply to re-manufacturing the standard units.

Steve

|

|

|

|

Post by dave1800 on May 27, 2017 0:57:17 GMT

Thanks Steve

You have confirmed my uderstanding that there was no advice about changing the fluid. I have read on various forums that people have used other fluid mixes, possibly without any corrosion inhibitors so it is very difficult to fully understand the reasons for internal failure.

Your point about insurance is very valid. I wonder what the approval process was for the MGF hydragas to coil conversions? With the hydrolastic crab issues what actually constitutes remanufacture, changing the hose fittings, replacing internal components, making new canisters? The crab suspension arrangement is such that in the case of displacer failure the car's handling, stability and braking were claimed to be unaffected. This may not be true for the huge number of after market coil over type conversions available for many other vehicles.

Maybe a good time to remind owners to ensure their crabs rubber bump stops are in good order!

Something that needs to be properly researched and costed; I will feed your comments to the 1100 group in the project lead.

I do agree with you that a crab without hydrolastic lacks appeal for me, but a number of members here have indicated they would want to consider coil or other alternatives. There is a Citroen DS here in the classic car club converted to coil suspension and Honda Prelude ruuning gear... it has quirky looks in its favour that I like, but other than that it is disappointing as was reflected in its recent sale price.

Thanks again

David

|

|

|

|

Post by steve4487 on May 27, 2017 20:51:14 GMT

David

As far as I am aware when a manufacturer alters a production car such as when the MGF was changed from Hydragas to coil suspension the changes would have had to be re-homologated. What constitutes re-manufacturer is a point an insurer would need to define.

From a car owners point of view any changes from a standard specification would have to be notified to an insurer no matter what that might be. Not notifying any changes can have very serious consequences see (http://www.dailymail.co.uk/news/article-4544528/Harlee-Pendergast-jailed-ploughing-pedestrians.html)

Though this is an extreme case this basically involved not disclosing modifications and this applies to any car when it comes to insuring. I was involved in this case and I inspected this chaps Mini following the accident. Though some might view having to inform an insurer of any modification from a standard specification nit picking it is when sometime terrible happens such as the above an insurer will use anything they can to absolve themselves of a responsibility to pay out.

Steve

|

|

|

|

Post by dave1800 on May 28, 2017 0:44:34 GMT

Thank Steve. That is very good advice. Strange that the modifications listed in the article were nitrous and LED lights, but it was the DM. I imagine many owners of modern cars have no idea when garages fit non OEM parts that include electronic units that can leave you stranded with the engine cut out in the fast lane which can be life threatening. A far as homologation is concerned this is something that needs to be further explored. The message is clear for classic (and other) car owners, declare everything it is then up to the insurers to determine whether they are satisfied. regards David David As far as I am aware when a manufacturer alters a production car such as when the MGF was changed from Hydragas to coil suspension the changes would have had to be re-homologated. What constitutes re-manufacturer is a point an insurer would need to define. From a car owners point of view any changes from a standard specification would have to be notified to an insurer no matter what that might be. Not notifying any changes can have very serious consequences see (http://www.dailymail.co.uk/news/article-4544528/Harlee-Pendergast-jailed-ploughing-pedestrians.html) Though this is an extreme case this basically involved not disclosing modifications and this applies to any car when it comes to insuring. I was involved in this case and I inspected this chaps Mini following the accident. Though some might view having to inform an insurer of any modification from a standard specification nit picking it is when sometime terrible happens such as the above an insurer will use anything they can to absolve themselves of a responsibility to pay out. Steve |

|

|

|

Post by steve4487 on May 29, 2017 10:01:41 GMT

David

You have got it spot on with regards to modifications from standard. The Mini inveigled in that horrific had a few more modifications that nitrous and LED lights. there were suspension and exhaust changes as well. With regard to LED head lights they can't be retro fitted to cars that are not fitted with head lamp washers and automatic height adjustment as that should result in an MOT fail.

Going back to the displacers my first recollection of a displacer failure was in 1989. The normal causes for low ride height was always a leak from one of the joints or valves. In all the years that i have worked on hydrolastic suspended cars '89 was the first time i had seen a failure. That's not bad when you consider how many springs and dampers failed over the same period.

Steve

|

|

|

|

Post by foglaursen on May 30, 2017 7:08:34 GMT

I can supply with this picture from the internet.  Peter  |

|

|

|

Post by 1800heap on May 30, 2017 9:43:12 GMT

Nice picture Peter That shows the shape of the rubber spring very nicely thanks. I hadn't realised the rubber ended up so close to the valve plate like this. Thanks Nick |

|

|

|

Post by foglaursen on May 30, 2017 10:30:48 GMT

I hadn't realised the rubber ended up so close to the valve plate like this.

Thanks

Nick[/quote]

I wondered about that too. In fact it doesn't. The displacer has been cut in two, so a small part of the metal in the middle is missing.

|

|

|

|

Post by Penguin45 on May 30, 2017 13:50:49 GMT

Fascinating. Have a big version.   Chris. |

|

|

|

Post by 1800heap on May 30, 2017 21:23:59 GMT

I hadn't realised the rubber ended up so close to the valve plate like this. Thanks Nick I wondered about that too. In fact it doesn't. The displacer has been cut in two, so a small part of the metal in the middle is missing. So it is, well spotted Peter. I didn't notice the second crimp missing! Much easier to see thanks Chris. Nick |

|

|

|

Post by hydrolastic on Aug 13, 2017 15:39:17 GMT

Hello, Cleaning up a rear displacer i saw a yellow dot on the side of it. just wondering if in the process of making the displacers there was a difference between the green (early 1100) and blue (late 1100) displacers? I know the cone is shorter on the green dot(vs blue) displacers but other than the cone was there an internal difference? Aaron

|

|

|

|

Post by 1800heap on Aug 14, 2017 3:41:15 GMT

Hi Aaron

At the moment the list of part numbers for the displacer type you are looking at is

47H9543 - 1800 / 1100

11H1888 - 1800

11H2158 - 1800

31G731 - 1100

31G8122 - 1100

37G5559 - 1100

Any additions or corrections to the list would be appreciated.

I have seen red dot (1800) and a blue dot displacer fitted to crabs. Mostly reds. I have not made any correlation for dot colour to part number as yet. I can't help you much with 1100 colours. I can tell you the likley differences will be to the cone, the rubber compound (Stiffness) of the spring (pipe end) and the damping rate set on the inturnal valves. I am unaware of any design difference inturnally. They certainly seem to be interchangeable given cone differences and hose length.

From the testing I have done on displacers to date, condition has a dramatic effect on the the displacer performance. I would say more so than any differences in the units given the correct length setting and ancillary parts.

A good indication of the condition of the spring rubber is the position of the hose crimp relative to the back of the displacer can, when depressurised. If you look accross the back of the displacer edge to edge, on a unit in good condition you will not see the hose crimp, just the hose. Imagine a straight edge accross the back of the can, the more the metal hose crimp crosses the straight edge the more deformed the rubber is! This is generally not good.

You can play with the length/pressures up to a point if you want to change how the displacer reacts. This will effect trim heights though.

Matching displacers is a good idea.

Pre-filling the unit before fitting it to the car is also a good idea. This is especially the case with the crab, as they lay on the side. If you are not evacuating the air before pressurising, prefilling the unit will help keep air to the minimum. Not evacuating happens alot as people generally use hand pumps for filling. Note this is only required when replacing displacers. Any air in the unit between the diaphram and valve plate will effect damping and any air effects the spring rate because of its compressability.

Hopefully I have been of some help!

Regards

Nick

|

|