|

|

Post by dave1800 on Aug 23, 2014 1:26:11 GMT

John Twist has posted a video showing what happens if you ride the clutch on a MGB. This can happen on the 1800 if there is any residual pressure in the clutch hydraulics due to sticking pistons or problems with the pipe collapsing as the soft graphite is designed to be in light contact with the clutch at all times. Worth remembering; it's a pain to replace. John TwistDavid |

|

|

|

Post by cptkennykidna on Sept 6, 2014 11:04:11 GMT

solution may be on the way, don't know how to post pictures but after 5 different experiments we think we have a roller thrust bearing that is up to the job, it is self centring and flat faced, it will fit old carrier if O.D. is enlarged down to same depth as carbon. there is one other mod but since your unit is out & the man on the lathe is being used, it's simple.

the part No will not bring you happiness as I think it is from an industrial application, but I can get it.

keep in touch.

|

|

|

|

Post by dave1800 on Sept 7, 2014 1:50:06 GMT

If you email me the pics I will post them for you regards David solution may be on the way, don't know how to post pictures but after 5 different experiments we think we have a roller thrust bearing that is up to the job, it is self centring and flat faced, it will fit old carrier if O.D. is enlarged down to same depth as carbon. there is one other mod but since your unit is out & the man on the lathe is being used, it's simple. the part No will not bring you happiness as I think it is from an industrial application, but I can get it. keep in touch. |

|

|

|

Post by tommydp on Sept 9, 2014 18:59:07 GMT

No doubt a clear message from Mr Twist!

Here's a technical tip from recent experience as a follow up..

I've always found the clutch operation on my white one far better than the blue. It used to be the other way around, but I changed over the complete hydraulic system when the blue was laid up:-). So I figured it had to be down to the hydraulics.

On the blue one I've really had to press it down to the floor to engage, likewise when shifting gears it has engaged almost as soon as the pedal is released. Pumping the pedal has sometimes improved things for a short while. Even after fitting a new master cylinder and new pins at pedal and slave pushrod, to take up slack, the pedal was sloppy and the actuating point way down against the floor.

I then had a look inside the slave cylinder. Pushed the piston all the way back, no need to remove the fluid, just open the master cylinder cap and put a rag under it in case it overflows.

The slave cylinder bore didn't look too bad, but I cleaned it with brake fluid and GENTLY used some 800 wet grind paper all around the bore. I guess the correct thing to do is to use a mini hone tool, but I don't have one:-)

Anyway, cleaned it all up and put it together. It improved amazingly, and it now feels even better than the white one. Very precise and firm, and the actuating point is way higher. Now it shifts into gear like a hot knife in butter. I guess some dirt etc inside the slave cylinder bore prevented the piston/ seal to go back as far as it should after clutching.

So, worth thinking of if you have a sloppy pedal and low clutch actuating point.

Regarding the release bearing, I think it's vital not to fit a longer slave pushrod as it could prevent the clutch fork/ release bearing from going back as far as supposed to. This could lead to extra wear on the bearing. The pushrod should be 63 mm if I remember correctly.

Regards, Tommy

|

|

|

|

Post by cptkennykidna on Sept 10, 2014 11:48:44 GMT

I hope people are listening to you tommy, keep it standard but clean.

a year or two out of service & you would be surprised at the build up of contaminants in your braking & clutch system, the seals are not expensive so don't risk it.

|

|

|

|

Post by dave1800 on Sept 11, 2014 1:25:50 GMT

Tommy This is very helpful and interesting and supports my belief that many of the strange clutch engagement problems are due to residual pressure in the hydraulics which also leads to and may be the primary cause of premature release bearing wear. As to the length of the pushrod, Tony's (Webmaster) excellent article on his website Austin Eighteenhundred indicates that there were three different push rod lengths, 68.25mm; 63.5mm and 58.7mm - in Australia as the design of the clutch components varied over the years. Whether this applied to UK produced cars I have no idea. So cptkennykidna's comments about the importance of keeping the seals in good condition fits in well with your findings. I wonder it it's worth considering having stainless steel inserts fitted into the clutch cylinders next time they are overhauled? I just wish I had thought all this through when I was younger it would have saved me money and many hours of unnecessary work.  But it wasn't just me, the BL garages routinely extended the pushrods to address complaints about clutches engaging with the pedal on the floor, potentially their action caused damage! Regards David No doubt a clear message from Mr Twist! Here's a technical tip from recent experience as a follow up.. The slave cylinder bore didn't look too bad, but I cleaned it with brake fluid and GENTLY used some 800 wet grind paper all around the bore. I guess the correct thing to do is to use a mini hone tool, but I don't have one:-) Anyway, cleaned it all up and put it together. It improved amazingly, and it now feels even better than the white one. Very precise and firm, and the actuating point is way higher. Now it shifts into gear like a hot knife in butter. I guess some dirt etc inside the slave cylinder bore prevented the piston/ seal to go back as far as it should after clutching. So, worth thinking of if you have a sloppy pedal and low clutch actuating point. Regarding the release bearing, I think it's vital not to fit a longer slave pushrod as it could prevent the clutch fork/ release bearing from going back as far as supposed to. This could lead to extra wear on the bearing. The pushrod should be 63 mm if I remember correctly. Regards, Tommy |

|

|

|

Post by cptkennykidna on Sept 11, 2014 13:07:13 GMT

I just spent 30 minutes typing my thoughts on clutch problems & pressed the green reply button, I think it is really a delete button, is that true?

|

|

|

|

Post by dave1800 on Sept 11, 2014 13:22:31 GMT

Sorry to hear that; I guess you probably have more experience of these clutches than the rest of us put together. I usually highlight what I have written and copy it into the computer memory (Control C) before I press the reply button as I have had this happen on just a few occasions. I can then paste it into a new reply by using (Control V). Of course the ones I lost were the lengthy answers! I will ask Chris our administrator to follow this up to see if it is a known fault that Proboards can resolve. regards David I just spent 30 minutes typing my thoughts on clutch problems & pressed the green reply button, I think it is really a delete button, is that true? |

|

|

|

Post by tommydp on Sept 11, 2014 14:01:40 GMT

Sorry to hear that.. It's happened to me too,lots of times, but I've always blamed the computer which is old and the net, which falls out now and then.

I have also made a habit of ctrl c when my post is getting long, in case I should lose it. If I have to write it again, I always feel I've lost something compared to the first draft..

I hope you'll give it another try later, as your knowledge is valuable. I'm sure others, like myself enjoy and learn a lot from other crab owners' knowledge.

It's important to share, to keep the cars on the roads and it sure can help many owners around the world, who have problems with the cars. I used to think I knew all about the 1800, but it's amazing how you learn new stuff almost every day through the internet. It's thanks to this I now feel I have two very reliable and well functioning 1800s in daily use! So keep up the good work. Perhaps a technical tip section could be an idea? Earth conversion, clutch mechanism, part interchange overview, modifications to name a few.

Regards, T

|

|

|

|

Post by Penguin45 on Sept 12, 2014 11:36:38 GMT

This may help if you use the "Quick Reply" box:  I'll try and write up a "How-to" at some point soon. Chris. |

|

|

|

Post by cptkennykidna on Sept 12, 2014 12:26:42 GMT

instead of 30 minutes, I am going to see if I can explain some clutch problems in 5.

1. clutch plate installed wrong way round, bold spring face has been installed facing flywheel.

result of incorrect installation is springs binding on flywheel bolts, but clutch can still work, in the ignorance of the installer you could still be better off than problem 2.

2. there where so many different applications for the clutch plates and pressure plates on so many different cars that you could end up with parts that will cause your car to want to move in any gear with clutch depressed and this can even happen after a years use of your clutch fix up.

what can cause it ?.

the pressure plates can have different inner diameters e.g. 122mm -129.5mm - 130mm - 145mm, and more. I am not talking about the machined recess, but the most inner i.d. .

now your clutch plate will also have as many variables with the raised spring face e.g. 116mm - 118mm - 120mm - 128mm and so on.

there must be clearance between raised spring o.d. on clutch plate & smaller i.d. on pressure plate or you are going to f up, and even the best of us do that, best wishes.

|

|

|

|

Post by dave1800 on Sept 13, 2014 1:53:07 GMT

Thanks for this info. It looks as though plenty of checks and measurements need to be made before installation. Gone are the days of a manufacturer's clutch kit with all the supposedly matched components. I think it's best to avoid the "Quick Reply" button altogether and use the "Quote" to avoid accidentally deleting your work. Weird and stupid labeling of the green "Reply" button. David instead of 30 minutes, I am going to see if I can explain some clutch problems in 5. 1. clutch plate installed wrong way round, bold spring face has been installed facing flywheel. result of incorrect installation is springs binding on flywheel bolts, but clutch can still work, in the ignorance of the installer you could still be better off than problem 2. 2. there where so many different applications for the clutch plates and pressure plates on so many different cars that you could end up with parts that will cause your car to want to move in any gear with clutch depressed and this can even happen after a years use of your clutch fix up. what can cause it ?. the pressure plates can have different inner diameters e.g. 122mm -129.5mm - 130mm - 145mm, and more. I am not talking about the machined recess, but the most inner i.d. . now your clutch plate will also have as many variables with the raised spring face e.g. 116mm - 118mm - 120mm - 128mm and so on. there must be clearance between raised spring o.d. on clutch plate & smaller i.d. on pressure plate or you are going to f up, and even the best of us do that, best wishes. |

|

|

|

Post by tommydp on Sept 16, 2014 19:37:53 GMT

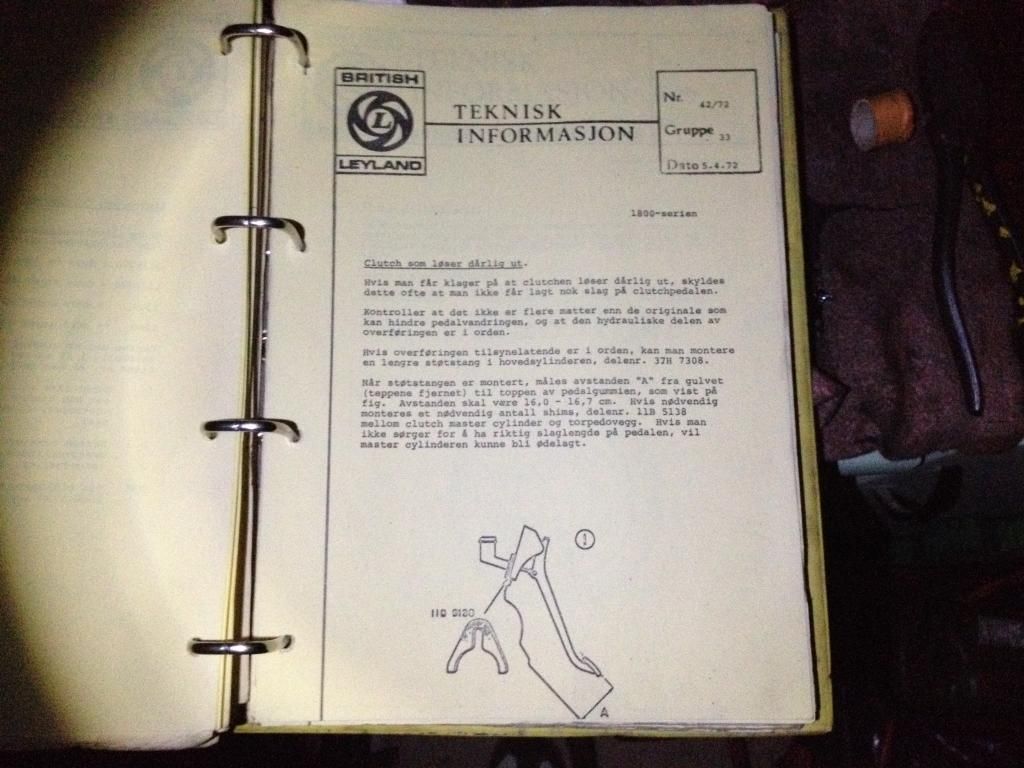

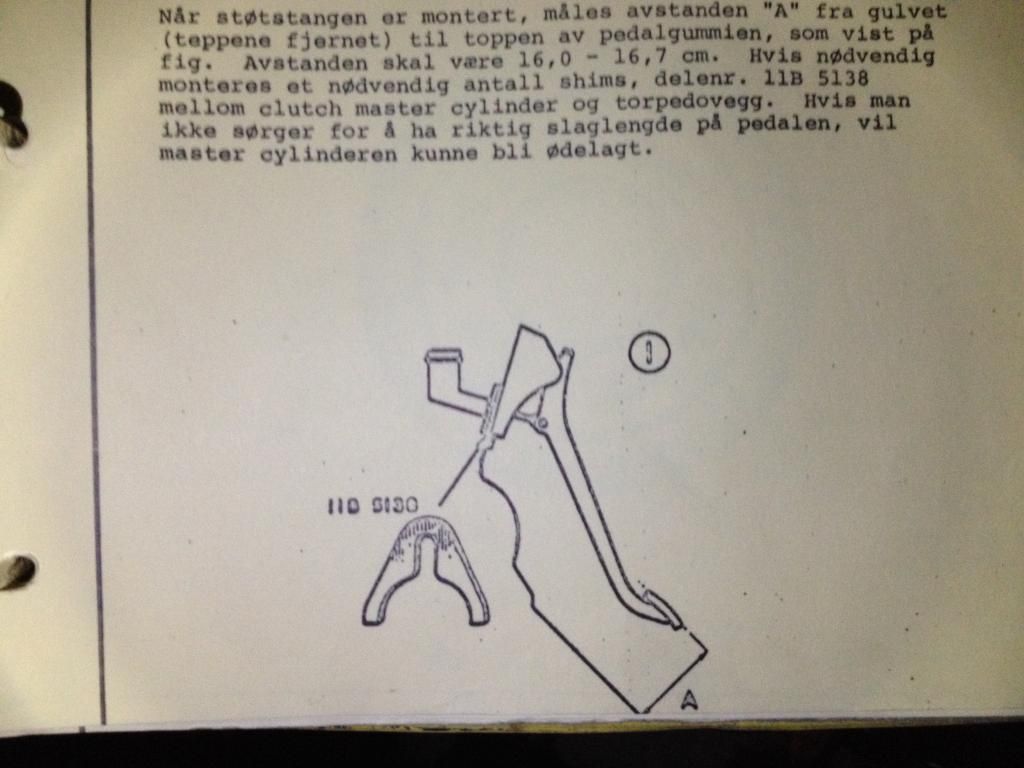

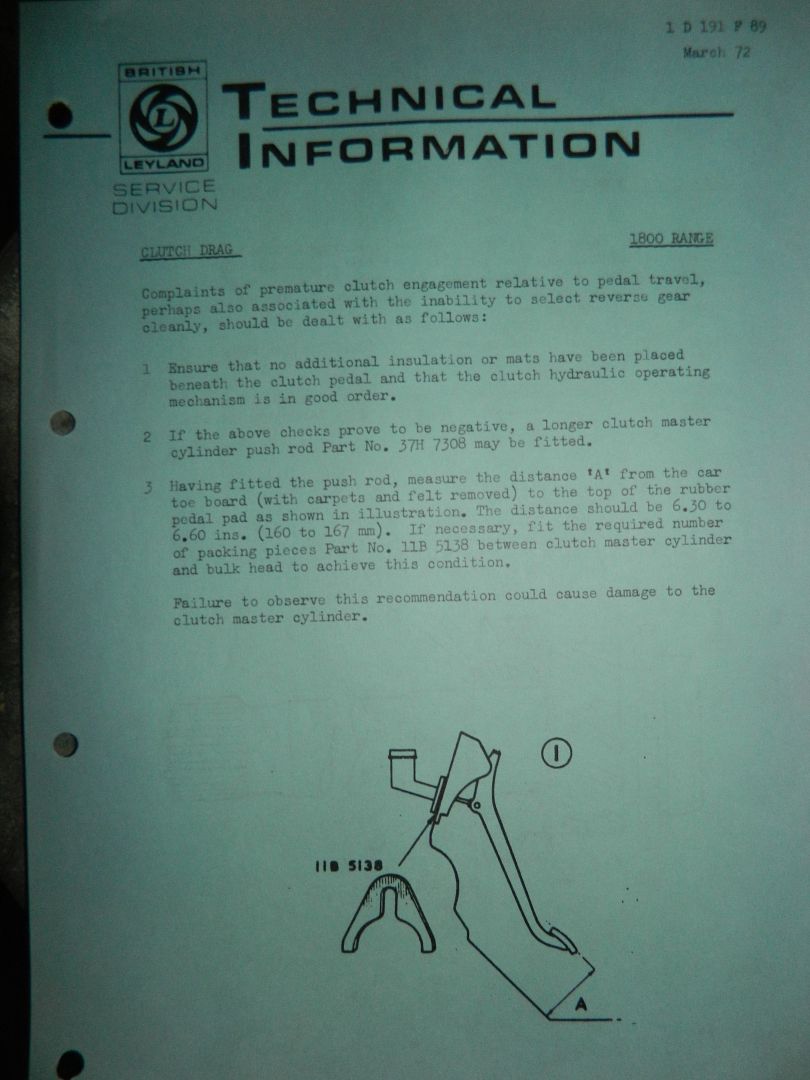

Perhaps not interesting or relevant at all, but as we're on the subject of clutch release here's from my folder of service bulletins from BL Norway, dated April '72. It goes more or less like this: "Clutch releasing insufficiently. Complaints on this is often down to too little stroke on the pedal. First, make sure there are no carpets or mats fitted, in addition to the original(!). Make sure the hydraulic parts are all in good order. If hydraulics are found OK a longer master cylinder pushrod, part number 37 H 7308, can be fitted. Distance A, see pic, from floor (carpets removed) to top of pedal rubber should be 16,0 - 16,7 cm. A selection of shims, part number 11 B 5138, can be mounted between bulkhead and master cylinder to achieve the correct pedal stroke. Inceorrect stroke of the pedal, may ruin the master cylinder". Well, for what it's worth. At least, I've never seen this distance mentioned anywhere else. I'm also starting to believe there could be differences between LHD and RHD models.   Regards, Tommy |

|

|

|

Post by dave1800 on Sept 17, 2014 11:49:06 GMT

Do you have the part numbers for the clutch components on LHD cars? I don't see why they should differ but this whole area seems to be cause for confusion. I think some of the extracts from your Norwegian manual look similar to the service notes issued in Australia (see Oz website and Tony's article)- and maybe also in the UK. But I've not seen them consolidated in any UK w/s manuals I have read. I think if you have a problem that develops over time your solution of ensuring all the seals and clutch hydraulic cylinders are perfect is where you should start. (Don't forget to check if the crankshaft thrust washers are worn by feeling for forward movement of the harmonic damper when the clutch pedal is depressed - this will cause the clutch to engage close to the floor). If the problem occurs after a clutch change then it could be a component mismatch that requires adjustments via changing the pushrod length or shimming of the m/s cylinder.

Any more thoughts or experiences from anyone here would be helpful.

David

|

|

|

|

Post by Penguin45 on Sept 25, 2014 19:45:01 GMT

Further to Tommy's extract from the Technical Bulletins, I've found a copy in English with Imperial measurements for us oldies.  Chris. |

|