How I set the preload.

I did a dry run first to work out what shims I needed before I covered everything in goo! If you are using OEM gaskets and have shims you won't need to do a dry run.

The WM suggests any shims you find when dismantling the diff should be replaced on the same side that they came from, so remember where they were!

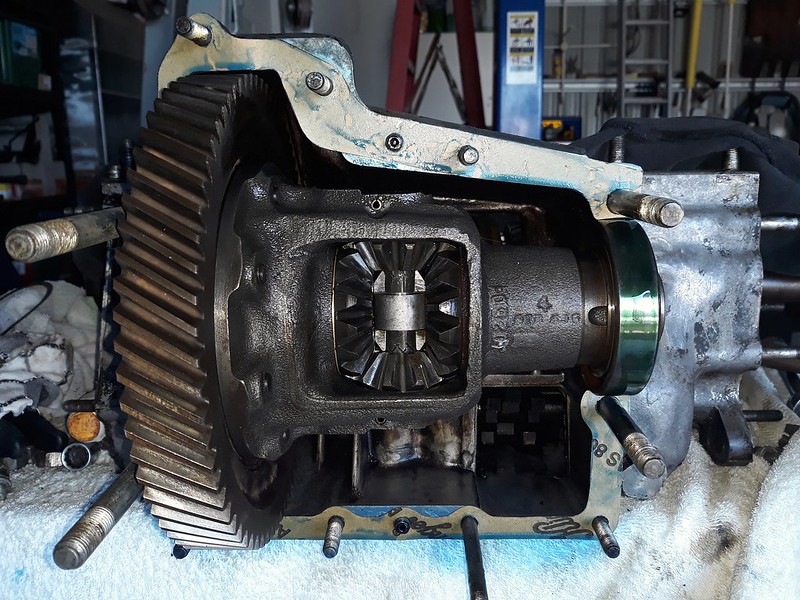

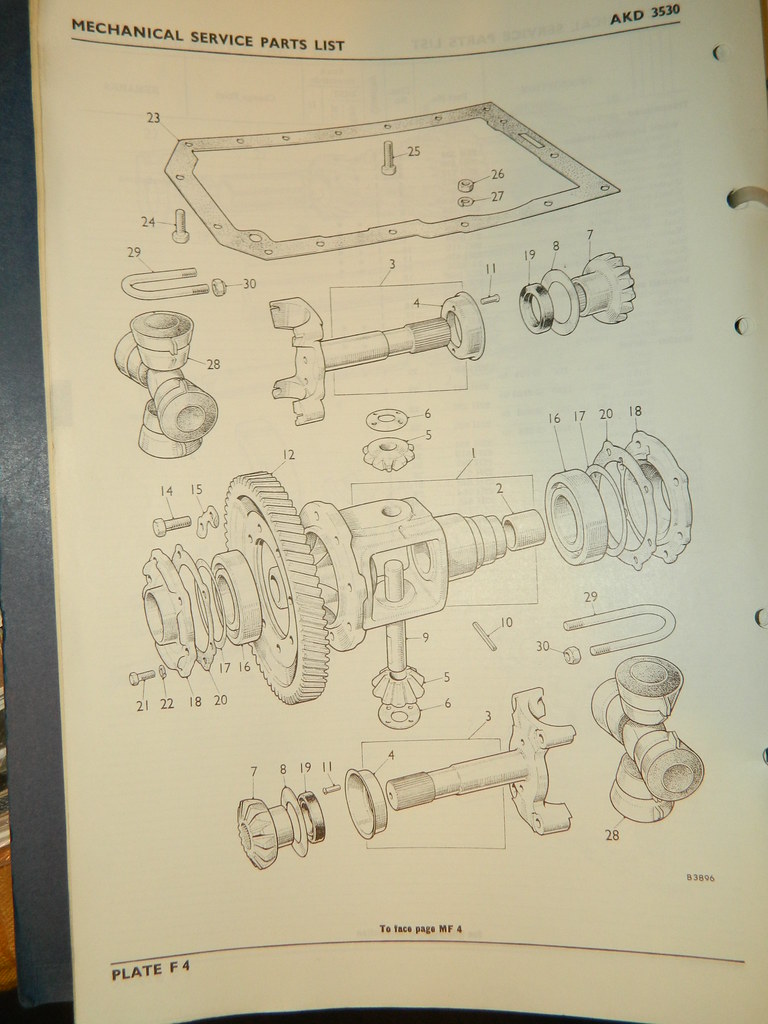

Assuming you have repaired the diff, checked bearings, cleaned it all up and are good to go. First put the upper and lower diff casing gaskets on the the gearbox.

You may need to trim your cover gaskets if they overhang here

and here

If you have no intention of removing it again put on some Hylomar or similar.

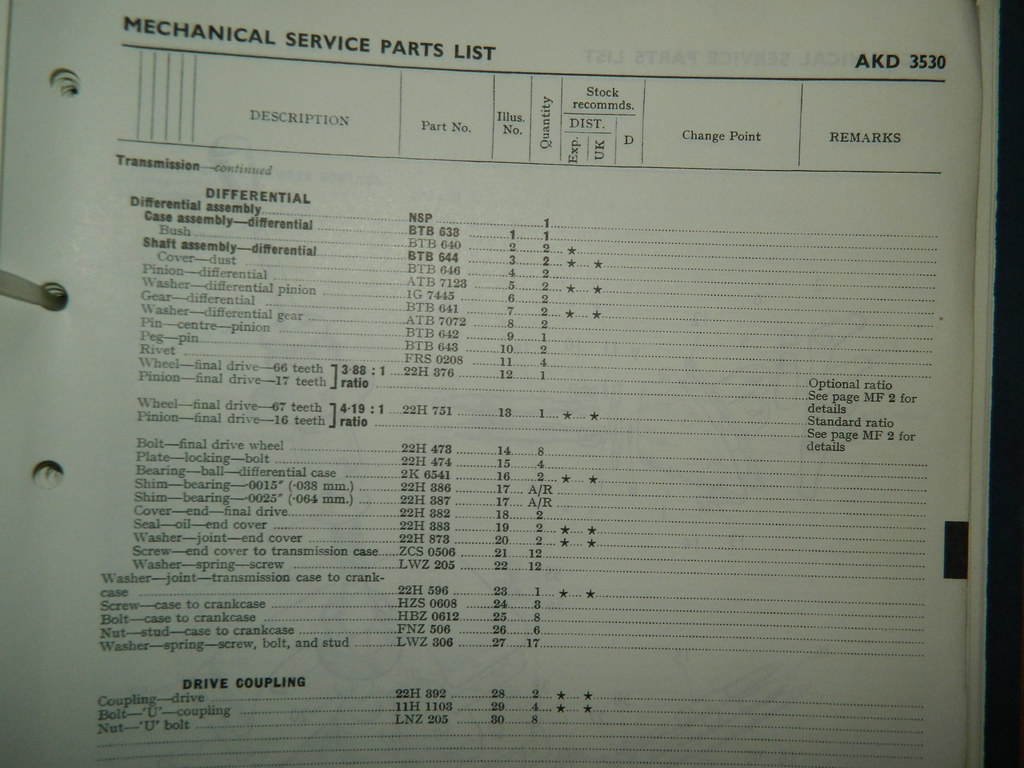

My gearbox was not fitted with shims so I have opted for the standard side for my shims. You can expect to required shims even if you didn't have any to start, with unless you have replaced both diff bearings. In this case you may not required any. Otherwise wear will usually make them necessary. The WM suggests the radiator side or closest to the front of the engine is where you normally put any shims bearing in mind the note above. You need to bias the diff to the right side for correct fitment of shims fitted on the radiator side or left. If you want the shims on the other side bias the diff to the left.

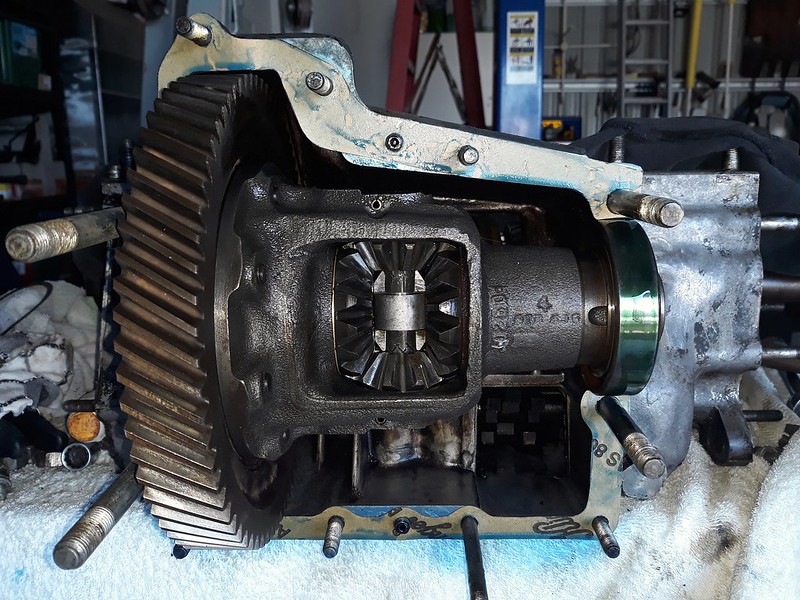

So in other words I am putting the diff back in more to the right than it should be. In the photo below the object is to get the gap shown by the arrows smaller on the right than the left. If you go too far the diff will bind on the casing though so check it turns OK before you put the cover on. Take care when turning the diff with the cover off as it may fall back out on your toes! Not something that happened to me I'm glad to say!

Now you have biased the diff put the main cover on and nip up the 11/16 nuts but don't bother with the others unless you are not taking it off again.

Next put the RH end cover and gasket on like this.

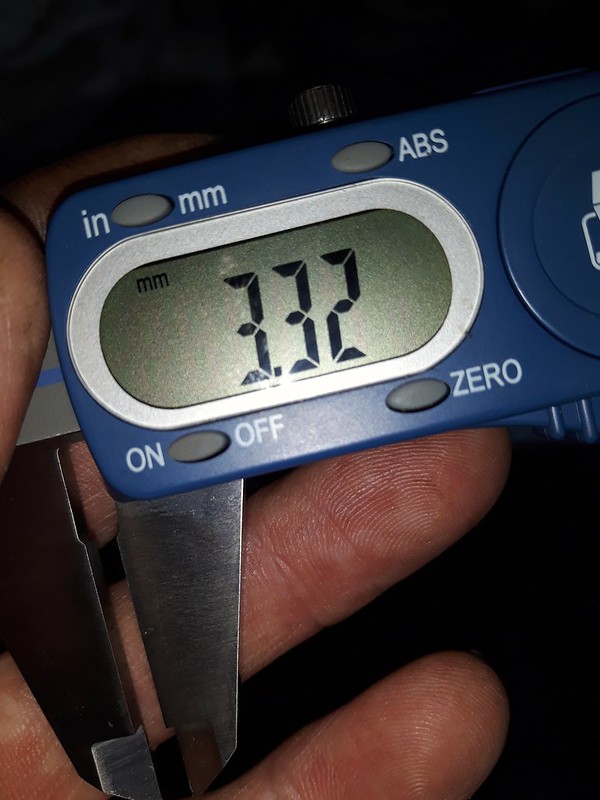

If you have got your bias correct the cover will not go all the way on when lightly nipped up. This is because it is hitting the outer race of the RH bearing. In the photo you can see I can get a feeler gauge in the gap. You will need enough gap here to take up all the play on the two bearings left and right. As you tighten the cover evenly the diff assembly is pushed to the left by the cover. To check if I had enough gap I used a set of calipers to check the distance on the left side before and after tightening the right hand cover.

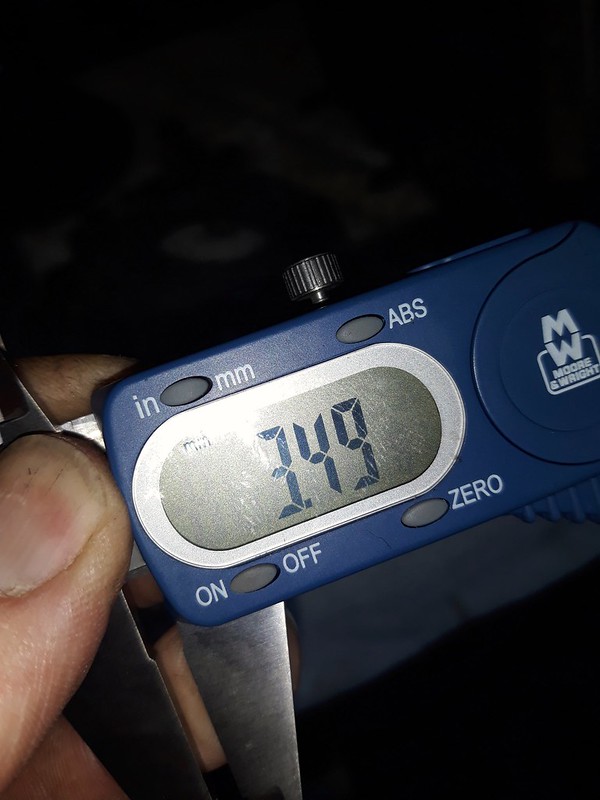

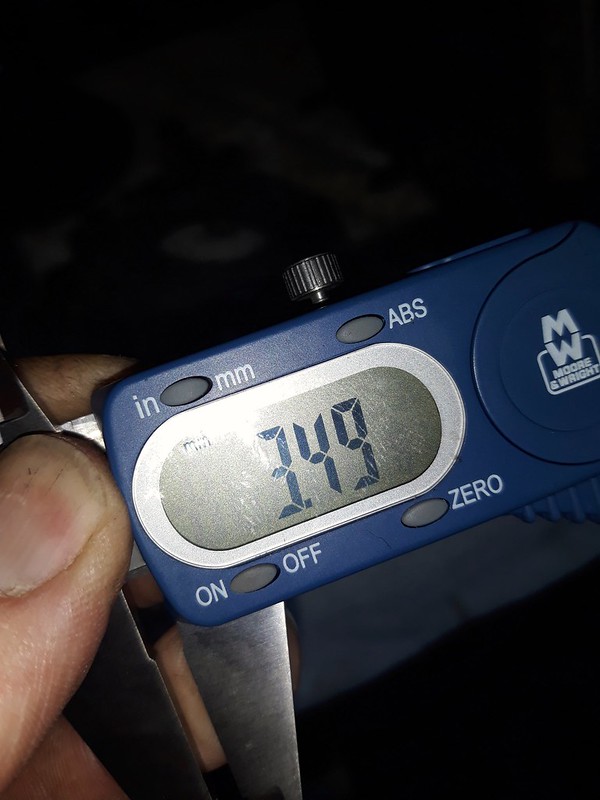

Distance before

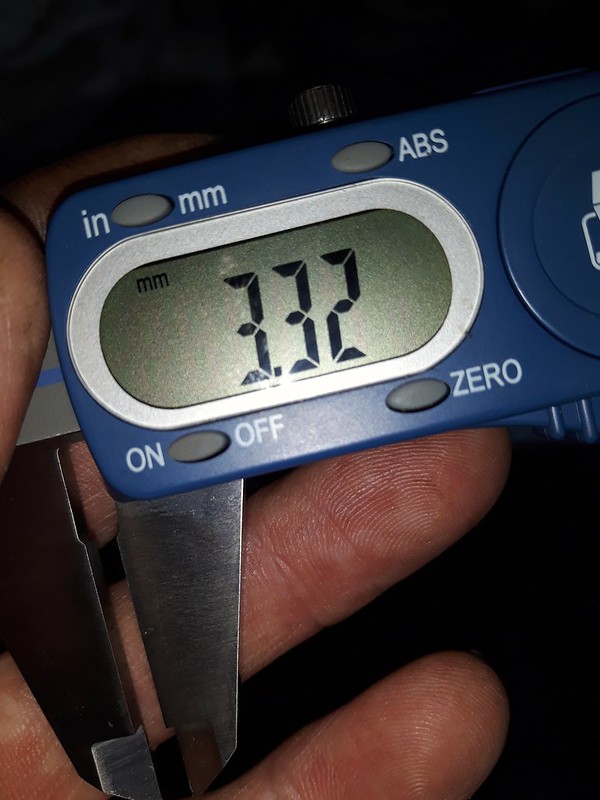

Distance after

The diff has moved sufficiently to the left to move the outer race of the left bearing. All the slack is gone and the preload is at zero now.

You need 0.003in to 0.005in which is where the shims come in, fitted under the LH cover.

I have not used standard gaskets so I can't use the table or calculation in the manual at this point. Also I am using metric sizes of gasket paper so sorry about the swap to metric units!! The method is similar though. Put the left hand cover on the diff without the gasket and see if you have a gap. Follow the WM from this point if you are using OEM gaskets to get your shim size.

Unfortunately I forgot to take a photo of putting the shims in. They go between the cover and the bearing outer race.

In this photo I have departed from the WM and have the cover gasket in place and initially had no gap. So a feeler gauge would not fit unlike with the one in the photo. I put a shim made of 0.24mm gasket paper in and still had no gap. I tried a 0.4mm one and had a gap of 0.07mm measured in several places with a feeler gauge. Obviously if you do not nip up the plate evenly the gap will not be even and the feeler gauge will not fit in all positions. You want an even gap for an accurate measurement. 0.4mm shim gave me about 3 thou and as I want to squash my shim a bit, being gasket paper not metal, I want a bit more than that so I moved to a 0.5mm gasket shim.

At this point I have 0.17mm or about 7 thou so Im happy, as my cover gasket will squash a bit and give me a bit more load than this. Remember my shim will squash as it is a gasket, so I can get away with a fair bit and not overload the bearings. The big disadvantage is the bearing may move because it is not sitting against something solid like a metal shim. I don't advise using as gasket shim because of this, as at this point I am taking a chance that this will work! I have however used a product on my outer bearing races called cyber bond to stick them to the case, so I am hoping this will keep them still.

You should be using the WM to calculate your shim size, as it accounts for the squash in the gaskets and you must get no more than 5 thou preload otherwise your diff will not be happy!!

Cyber bond applied to the outer races on my diff

I pulled it all apart and used Hylomar to reassemble after the dry run so here are a few more pictures of this.

you can see the green cyber bond on the bearing race.

That's about it I think apart from tightening it all up to the WM spec

Nick

Book of Records guys.

Book of Records guys.